Grex Power Tools X1000 User Manual

Page 2

705 South Electric A

ve. Alhambra CA, 91803

626.289.7618 Fax: 626.289-8121 [email protected]

© 2005 Grex Power T

ools. All Rights Reserved.

All

Grex

spray

guns

are

warranted

against

manufacturing

defects

of

material

and

manufacture

or

workmanship

for

a

period

of

ONE

year

from

the

original

date

of

purchase.

This

warranty

does

not

cover

fluid

needles,

fluid

nozzles

and

o-rings

since

these

parts

need

to

be

replaced

occasionally

due

to

normal

wear

. Any

parts

of

the

product

covered

under

this

warranty

will

be

repaired

or

replaced

at

our

option,

which

after

examination

proves

to

be defective in workmanship or material during the warranty per

iod.

This

warranty

does

not

apply

to

repair

or

replacement

parts

required

due

to

misuse,

abuse,

normal

wear

and

tear

or

repairs

and

alterations

attempted.

In

no

event

shall

Grex

be

liable

for

any

indirect,

incidental,

or

consequential

damage

from

the

sales

or

use

of

this

product.

This

disclaimer

applies

both

during

and

after

the

term

of

this

warranty

.

This

is

the

only

warranty

and

our

company

makes

no

warranties

express

or

implied,

including

merchantability

and fitness for a practical purpose, after the one year term of

this warranty

.

This limited warranty gives you specific rights and you may als

o have other rights, which vary from state to state.

W

ARRANTY

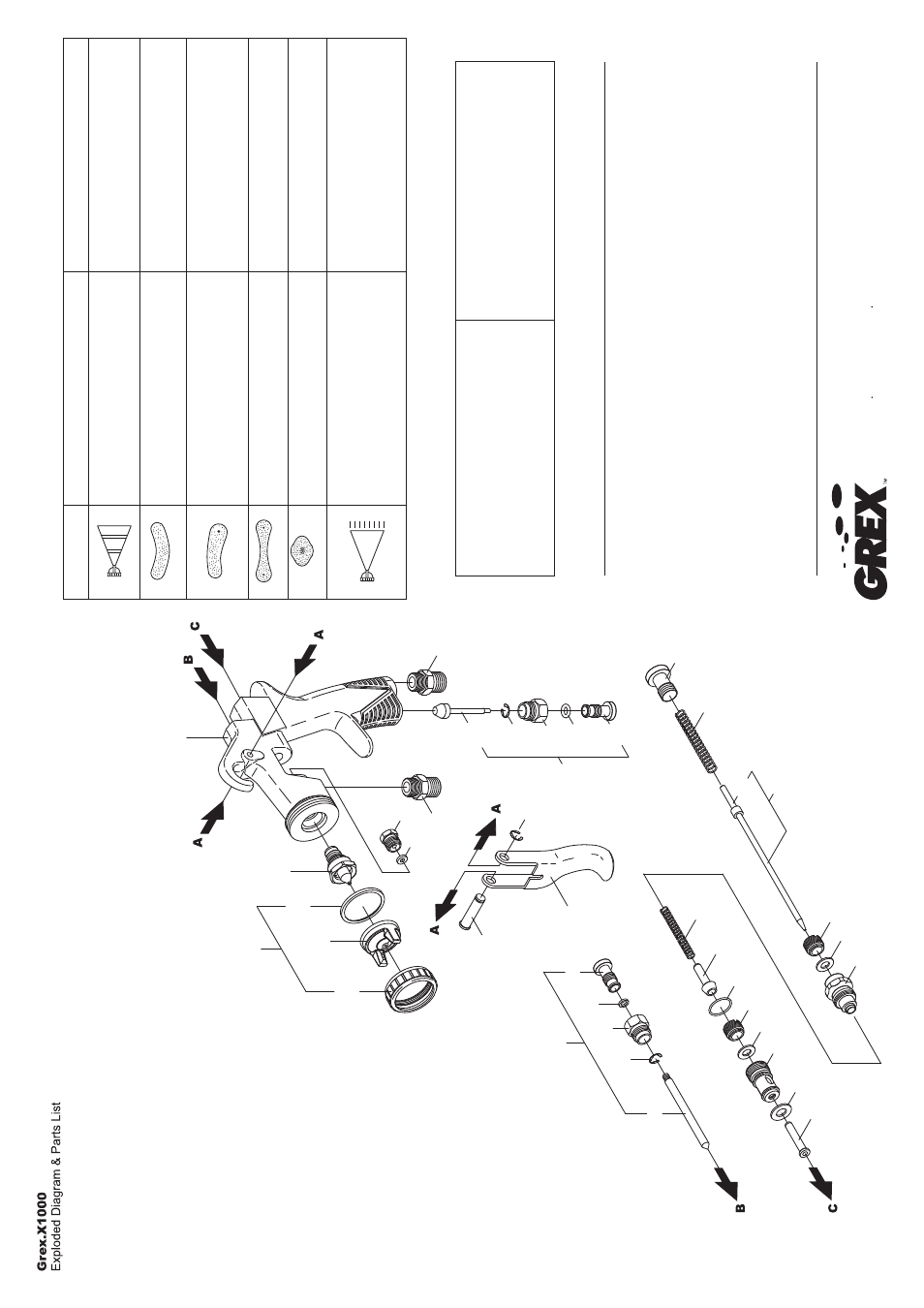

No.

1 1-1 1-2 1-3 2 3 3-1 4 5 6 6-1 6-2 6-3 6-4 6-5 7 8 9 10 11 12 12-1 12-2 12-3 13 14 15 15-1 15-2 16 17 17-1 17-2 17-3 17-4 17-5 18 19 20

Part No.

X1000NCS A150027 A041000 A120006 A051000 A021000 A150028 A120008 A150029 X1000ACA A150030 A150031 A150032 A120009 A150033 A01

1000

A1

10006

A150034 A150035 A120007 A150036 A120010 A150037 A060008 A150038 A1

10007

A150039 A12001

1

A150040 A150041 X1000A

VA

A150042 A150043 A150044 A120012 A150045 A150046 A150047 A150048

Part Description

Air Nozzle Cap Set Brass Ring Air Nozzle Teflon Ring Fluid Nozzle Fluid Needle Fluid Needle Seat Needle Packing Needle Packing Seat Fan Air Control Assembly Air Piston E-Ring Air Control Seat Teflon O-Ring Air Control Knob Spray Gun Body Fluid Needle Spring Fluid Adjust Knob Air V

alve Stem

Teflon O-Ring Air V

alve Seat Set

Gasket Seat Nut O-Ring Air V

alve

Air V

alve Spring

Fluid Adjust Guide Set Teflon O-Ring Guide Nut Air Nipple Air Regulator Air Piston E-Ring Air Control Seat Teflon O-Ring Air Control Knob Trigger Stud Trigger E-Ring

TROUBLESHOOTING GUIDE

Air

enters

between

fluid

nozzle

and

seat

of gun body

.

Air is suctioned from fluid needle

packing.

Paint

buildup

on

air

cap

partially

clogs

horn

holes.

Air

pressure

from

both

horns

dif

fers.

Paint

buildup

on

air

cap

partially

clogs

horn

hole

or

air

cap

center

hole,

or

causes

damage

Loose fluid nozzle

Paint viscosity too low

Fluid output too high

Paint viscosity too high

Fluid output too low

Fluid

nozzle

and

fluid

needle

set

are

not

seated properly

.

The

first

stage

travel

of

trigger

(when

only

air discharges) decreases.

Paint buildup inside air cap set.

1.

2.

1.

1.

2.

1.

2.

1.

2.

1.

2.

3.

Remove fluid nozzle to clean seat

Tighten fluid needle packing.

Remove

obstructions

from

horn

holes,

but

do

not

use

metal

objects

to

clean

horn

holes.

Remove obstructions. Replace if damaged

Remove nozzle and clean seated

section

Add paint to increase viscosity

Adjust fluid or pattern adjustment knob

Reduce viscosity

Increase fluid output

Clean

or

replace

fluid

nozzle

and

fluid

needle set.

Replace fluid nozzle and fluid needle set.

Clean air cap set.

1.

2.

1.

1.

2.

1.

2.

1.

2.

1.

2.

3.

Problem

Remedies

Spray Pattern

Spit

Heavy Center

Split

Inclining

Crescent

Fluttering

Air Consumption Fluid Output Air Inlet Fluid Inlet W

orking Pressure

7 cfm (200 L/min) 115 mL/min 1/4” NPS 1/4” NPS 30 ~ 45 psi

TECHNICAL

SPECIFICA

TIONS

Fluid Nozzle Feed T

ype

Fluid Capacity Container T

ype

Pattern Width W

eight

1.0 mm Side Gravity 8.5 oz. (250 ml) Side detachable cup 11” (280 mm) 1.3 lbs. (0.58 kgs)

6-5

6-2

6-1

6-4

6-3

6

1-1

1-2

1-3

2

16

1

4

16

17-1

17-2

17-3

17-4

17-5

17

20

19

18

5

7

3-1

15-2

15-1

15

3

8

9

10

11

12

12-1

12-2

12-3

13

14