2 generator compartments, 3 suspended mounting, 4 generator restraint – Generac 004702-0 User Manual

Page 25: 1 compartment size, 2 compartment construction

Generac

®

Power Systems, Inc.

23

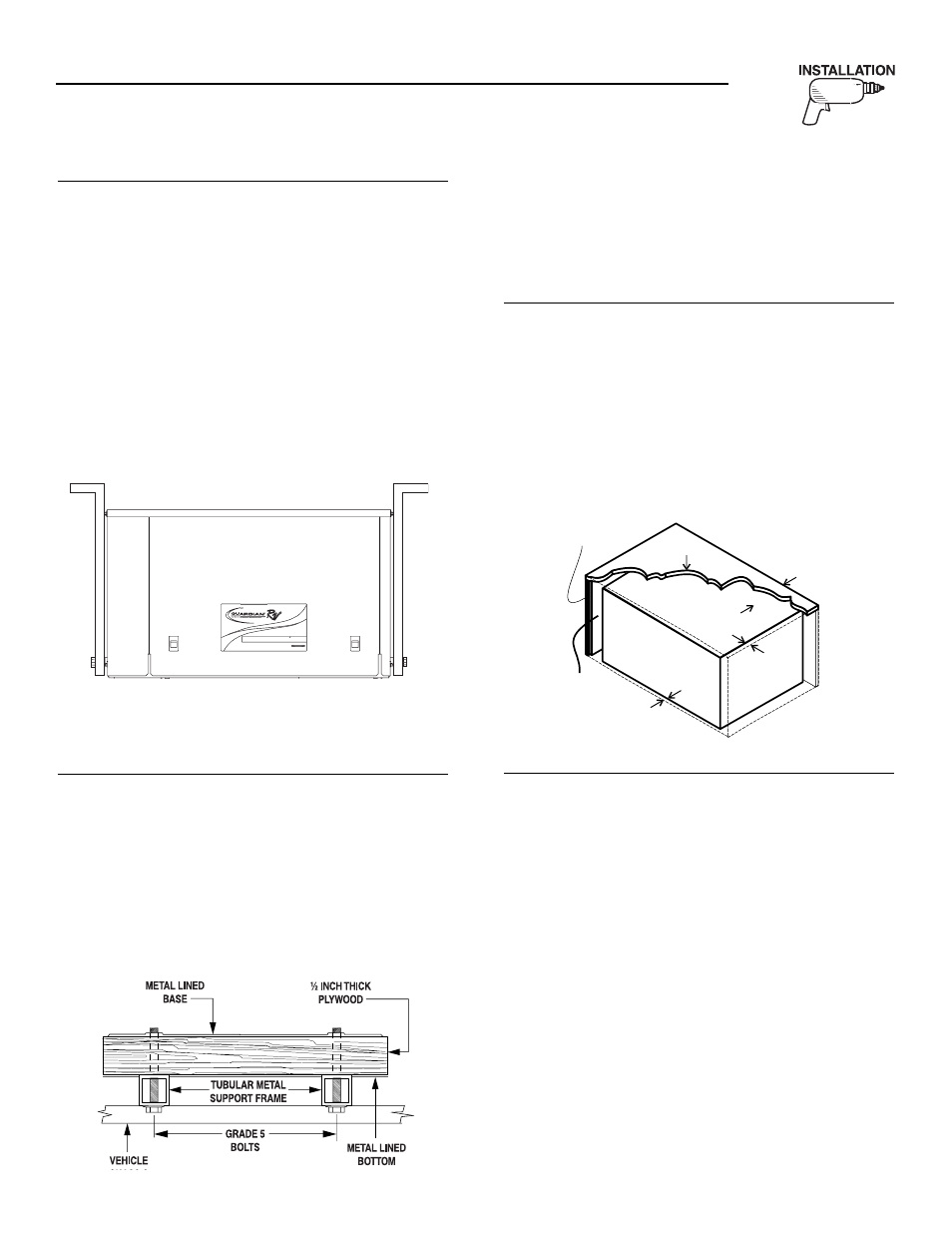

6.1.3 SUSPENDED MOUNTING

If you are going to suspend the generator below the

horizontal support tubing, the suspension method

you use with the vehicle frame members must (a) be

able to support the weight of the generator AND (b)

provide sufficient restraint for the generator. One typ-

ical suspended mounting system is shown in Figure

6.2. The location of a suspended mounting system

must be carefully planned, keeping the following gen-

eral rules in mind:

• Protect the generator against road splash and debris.

Baffles or splash guards may be required to protect

certain areas of the generator. To make sure the gen-

erator is adequately protected, road test the installa-

tion through mud, water and slush.

Figure 6.2 – Typical Suspended Mounting System

• The installer must make certain that the selected

location will permit adequate cooling and ventilat-

ing airflow to be supplied.

6.1.4 GENERATOR RESTRAINT

Use four 3/8"-16 hardened steel bolts (Grade 5) to fas-

ten the generator to the supporting frame or the sup-

port tubing. These bolts must pass through (a) the gen-

erator mounting base, (b) the compartment floor (if a

compartment is used) and (c) the supporting frame-

work (Figure 6.3). All bolts must be long enough so that

when tight, at least three threads are visible past the

retaining lock nuts. Refer to Section 6.2 for the location

of the generator mounting holes.

Figure 6.3 – Typical Generator Restraint

6.2 GENERATOR

COMPARTMENTS

Whether the generator set is being installed inside a

compartment specifically manufactured to house a gen-

erator or inside a compartment that the installer con-

structs, the compartment MUST meet certain specifi-

cations as outlined in the following sections:

6.2.1 COMPARTMENT SIZE

Plan the compartment size carefully. Provide a mini-

mum clearance of 1/2 inch (13 mm) on the front and

top, 1 inch (25 mm) on the sides, and 1/2 inch (13

mm) from the back for air circulation AFTER the

compartment has been lined with metal and sound

insulation (Figure 6.4).

NOTE:

Refer to “Figure 5.2 – Major Features and

Dimensions” on Page 21.

Figure 6.4 – Clearances

6.2.2 COMPARTMENT CONSTRUCTION

• The generator compartment should be either con-

structed of, or lined with, 26-gauge galvanized

steel.

NOTE:

Aluminum is NOT an acceptable alternative

to galvanized steel due to aluminum’s low melting

point.

• If the compartment is lined with galvanized steel, it

may be constructed of any material. Generac rec-

ommends that the compartment be constructed of

1/2-inch thick plywood (not strandboard), with the

floor made of a double thickness of 1/2-inch ply-

wood with the grain of the wood at cross section

for added strength (Figure 6.5).

◆

1" Clearance

in Back

1/2" Clearance on Top

1" Each Side

1/2"

in Front

Insulation

Plywood

Compartment

◆

◆

POWERED BY GUARDIAN 760cc OHVI V-TWIN

QUIETPACT

INDUSTRIAL

55G

◆

Section 6 – Installation

QUIETPACT 55, 65, and 75 Recreational Vehicle Generators