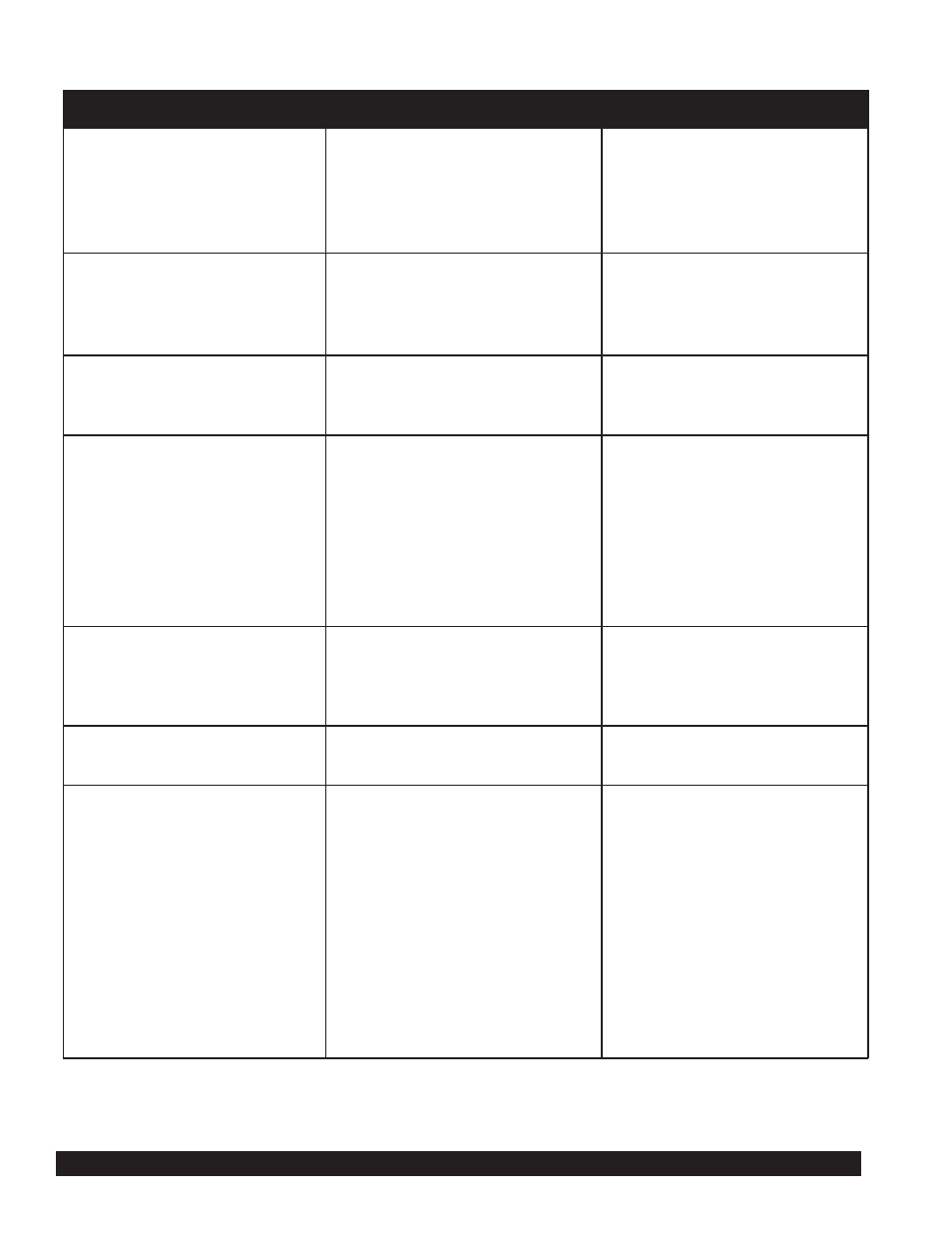

Troubleshooting guide (cont’d), Page 18 g & mg series granita machine, Problem possible cause solution – Grindmaster G23-2B User Manual

Page 18

Page 18

G & MG Series Granita Machine

Troubleshooting Guide (cont’d)

Problem

Possible Cause

Solution

If you still need help, call our service department at (800) 695-4500 (USA & Canada only) or (502) 425-4776 (Monday

through Friday, 8 am - 6 pm EST) or an authorized service center in your area. Please have the model and serial

numbers ready so that accurate information may be given.

Prior authorization must be obtained from Grindmaster Corporation’s Technical Services Department for all

warranty claims.

Product is leaking from the

dispensing valve

Product is flowing into drain tray

through drainage tube

The auger and/or the upper mixing

unit is not turning

The auger and/or the upper mixing

units are creating noises as they

rotate

There is no light in the

merchandising lid or rear

merchandising panel

The cover does not fit properly on

the bowl

“Filtr” or “Err” message appears on

the touchpad LED readout

• Reassemble and replace

• Clean and lubricate the valve and

valve cylinder with the lubricant pro-

vided with the machine

• Replace the o-rings

• Find the seal and put it back in place

• Replace the damaged/worn seal and

check the condition of the driveshaft.

• Turn auger on

• Check the contacts and correct the

ones that are incomplete

• Replace the gear motor(s)

• Check and correct

• Check the product brix and correct

• Replace or Clean and lubricate with

the lubricant provided with the

machine

• Check and correct

• Replace (See “Changing the lightbulb”

section in this manual)

• Replace

• Replace

• Remove bowl and position properly

• Clean and replace filter following

instructions on page 11 (Removing

and Cleaning Filter)

• Reposition unit to maximize ventilation

space (see page 2 - installation figures)

• Properly install filter see “Removing and

cleaning filter” page 11

• Reposition unit to maximize ventilation

space (see page 2 - installation figures)

• The dispensing valve has been incom-

pletely or incorrectly replaced in its

position

• The free movement of the dispensing

valve is impeded

• Dispensing valve o-rings are damaged

• The bell shaped “shaft” seal between

the front of the cylinder and the auger

hub has not been reinstalled properly

• The bell shaped “shaft” seal or the

spindle bushing seal is damaged or

worn

• Auger not turned on

• Some electrical connections are not

complete

• The gear motor(s) are malfunctioning

• The large red bowl seal is not in

position, causing the gear teeth not to

mesh

• The product brix is incorrect

• The bell shaped “shaft” seal has been

replaced without lubrication or is dam-

aged

• The auger has been incompletely or

incorrectly reassembled (ie the

auger’s gear pins are not properly

seated)

• The light bulb is burnt out

• The 5 Amp fuse between the trans-

former and the lamp is blown

• The transformer is blown

• The bowl is incorrectly positioned (the

lower, outside corner is not over the

lower, outside base piece)

• The filter is dirty and needs to be

cleaned

• The unit is positioned too close to a

wall or other object restricting air flow

and causing the machine to run at a

higher temperature

• The filter is not properly installed

• The unit has been installed near a

heat source, such as a coffee

machine, ice maker or cold beverage

machine which expels hot air from its

vents, causing the machine to run at a

high temperature. (Installation near a

heat source should be avoided)