Venting, Figure 3 - vent location limitations – GSW 61009 REV. C (09-03) User Manual

Page 6

– 6 –

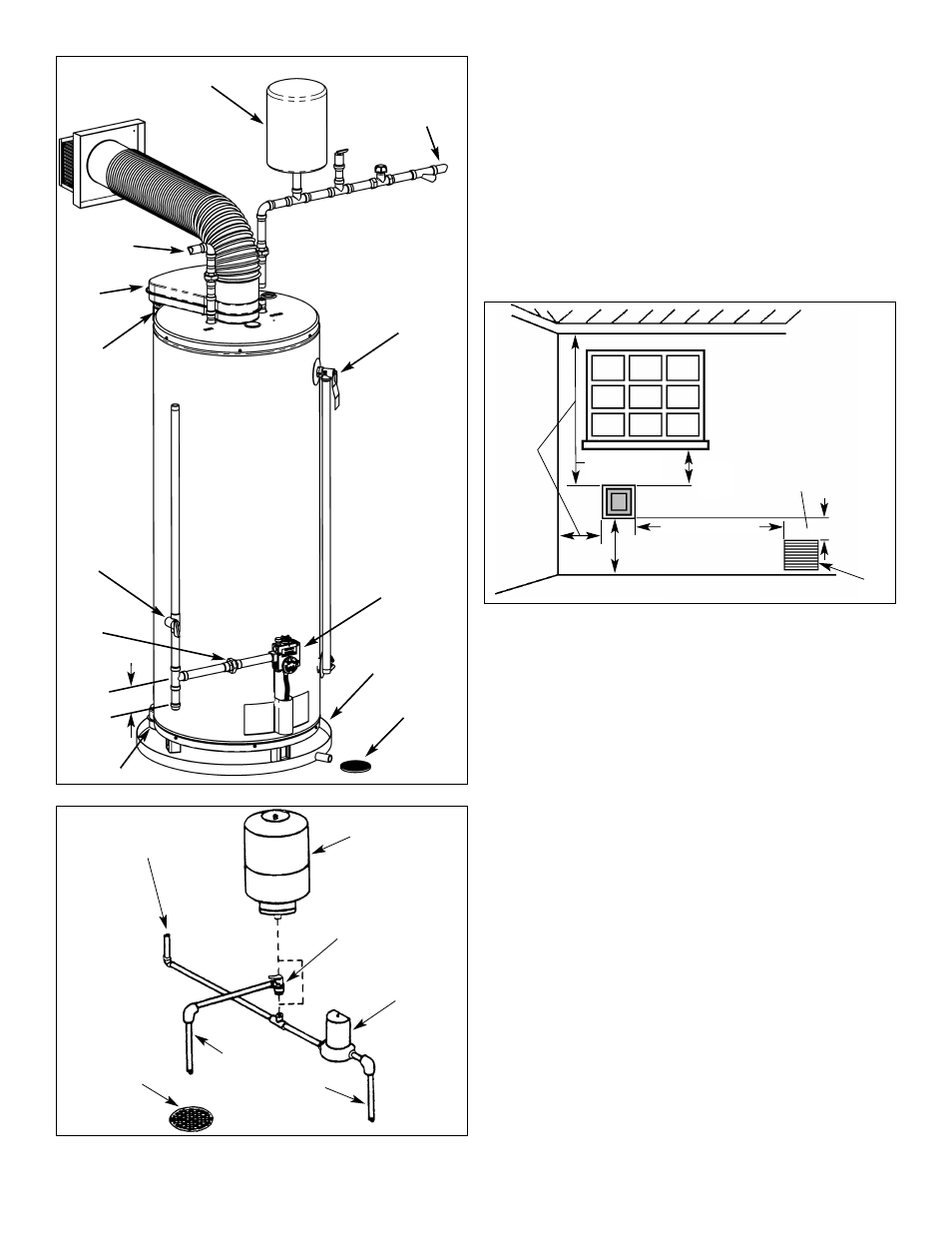

Figure 2A - Installation Components.

Figure 2B - Installation Options.

Figure 2B shows the location of a pressure relief and/or

expansion tank if a check valve or pressure-reducing valve

is in the cold water supply to the house.

Use OPTION 1 or 2 whichever is more convenient. If pres-

sure relief valve is used, select one with a setting 172 kPa

(25 psi) below the T&P valve rating at tank.

Venting

Make certain to observe the vent location limitations com-

plying with the "Natural Gas and Propane Installation

Code" CAN/CSA-B149.1 or "National Fuel Gas Code"

ANSI Z223.1 (NFPA 54) and/or local codes. There is some

important information shown in Figure 3.

For a second or more direct vent unit, the distance between

vent terminals must have a minimum of 305mm (12 in.).

INSPECT SHIPMENT –– There may be hidden damage

caused by transit. Check to be certain all parts of the vent-

ing system, as shown in Figures 3A through 3M, are pres-

ent. Inspect the upper and lower air inlet boxes, rear air tube

and all parts of the venting system (see Figure 2A).

CAUTION

If there are any damaged parts, DO NOT install this water

heater. Report any shortage to your distributor and damage

to your carrier.

Note: The four fasteners that are required to secure the

vent terminal to the exterior wall are not provided. These

should be screw type (not nails) chosen for the type of con-

struction and obtained locally.

CAUTION

Cut edges of corrugated (flex) pipe are extremely sharp.

Wear gloves when handling.

OPTION 1

OPTION 2

SEDIMENT

TRAP

152mm (6 in.)

HOT WATER

OUTLET

GAS SUPPLY

MANUAL

SHUT-OFF

VALVE

GROUND-JOINT

UNION

FLOOR DRAIN

TEMPERATURE

& PRESSURE

RELIEF VALVE

COLD WATER

INLET

GAS CONTROL

UPPER AIR

INLET BOX

REAR AIR

TUBE

DRAIN PAN

EXPANSION TANK

WATER SUPPLY

TO HOME

WATER METER

WITH BACKFLOW

PREVENTER

P R E S S U R E

RELIEF VALVE

OVERFLOW

WATER SUPPLY

TO METER

FLOOR DRAIN

Figure 3 - Vent Location Limitations

Vent Terminal must be located at

least 305mm (12 in.) from

Windows, Doors, or any other

Opening through which flue

gases could enter the building.

Any Forced Air Inlet

into the building

V

ent

Terminal must be located at least 457mm

(18 in.) from any overhang or building corner

or other irregularity

.

305mm (12 in.) Min.

above grade. Higher in

Areas of Heavy Snowfall

Within 1.8m (6 ft.)

915mm

(36 in.)

Min.

305mm

(12 in.)

Min.

Vent terminal must

be located at least

915mm (36 in.)

above any Forced Air

Inlet into the building

within 3m (10 ft.) of

the Vent Terminal

457mm (18 in.)

Min.

EXPANSION

TANK

LOWER AIR

INLET BOX