Engineer” program settings – Grindmaster LIQUID COFFEE DISPENSER LCD-2A User Manual

Page 11

Page 11

Model LCD-2R and LCD-2A

“Engineer” Program Settings

TO BE PERFORMED BY A QUALIFIED SERVICE TECHNICIAN ONLY

Machine Fault Codes (cont.)

6: Water overheat

The thermistor has detected the water is too hot. The boiler element contactor may have failed short circuit. The

machine may be running high Wattage Power with a preheater.

7: Leak

If the machine refills 15 times without a dispense the machine assumes a leak. A water outlet valve may be leaking.

8: Inlet valve leak

Not available with single inlet valve machines

9: Tank thermistor fail

The thermistor has failed open circuit, or connections from the thermistor to the PCB may have failed.

10: Reset System

The watchdog timer on the control chip has timed out, the machine needs a reset. (Turn machine off, wait 5 sec-

onds, turn back on).

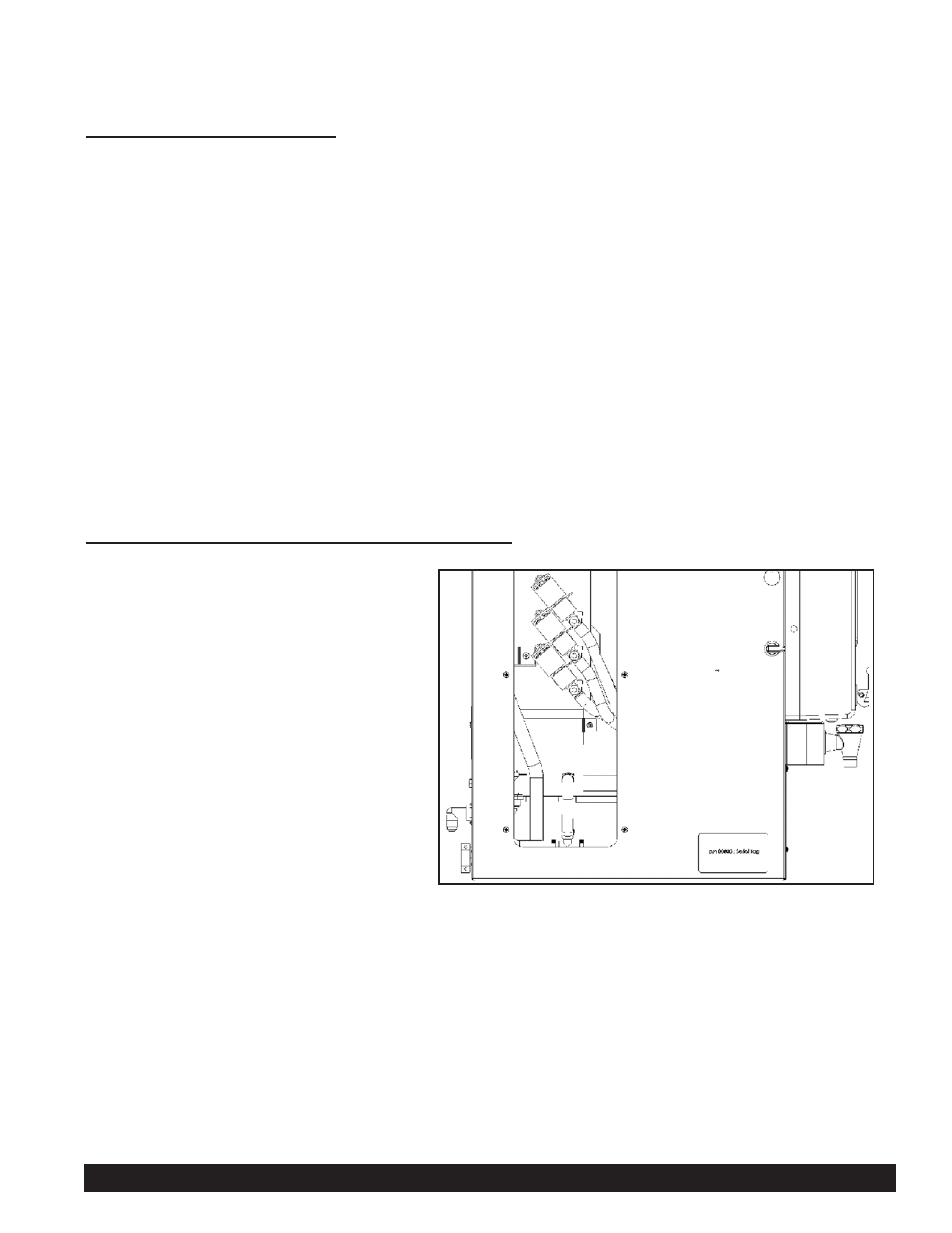

Programming Guide for Calibration of Mix Ratio

(refer to Figure D)

Figure D

1. The water dump valves are factory set to

60 ml/sec (2 fl-ounces per second). If

adjustment is required, disconnect power to

the machine and remove the left side

access plate to gain access to the dump

valves.

2. Using an appropriate hex key, turn the

adjustment screw on each dump valve

clockwise to fully close the adjustor (Do not

force the adjustment as permanent damage

can occur to the valve)

3. Turn each dump valve adjustor counter

clockwise as indicated below to achieve

(2) fl-ounce per second.

Top valve =

Left dispense head= 5.5 turns out CCW

Middle valve=

Middle dispense head= 4.5 turns out CCW

Bottom valve =

Right dispense head= 4.0 turns out CCW

4. Reassemble machine and power ON.