Troubleshooting guide, Problem possible cause remedy – Grindmaster GRIND'N BREW 21H User Manual

Page 15

Grind’n Brew® Coffee Systems Page 15

ƽ

CAUTION: Unplug power cord from outlet before cleaning or servicing the unit.

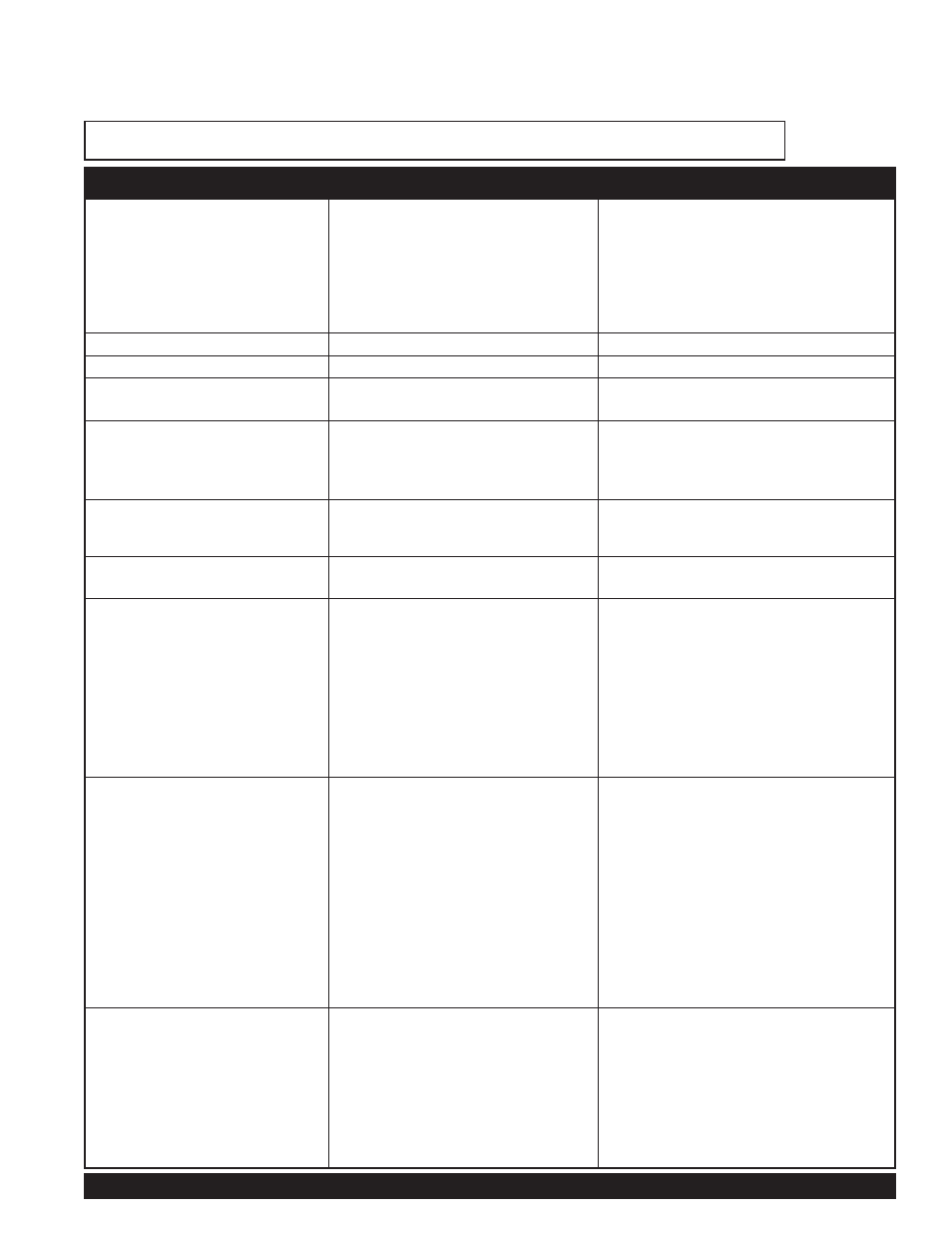

Troubleshooting Guide

The following procedures must be performed by a qualified service technician.

Problem

Possible Cause

Remedy

Weak coffee

• Not enough coffee used

• Grind is too coarse

• Water not hot enough

• Too much water used (half brews)

• Coffee bed has dry areas

• Set to portion more coffee.

• Readjust grind to a finer grind.

• Check spray temp, should be

greater than 185°F.

• Adjust brew time at the controller.

• Spray deflector broken or missing.

Replace.

Strong coffee

• Too much coffee used

• Readjust coffee portion.

Bitter coffee

• Grind is too fine

• Coarsen grind setting.

Grounds in coffee

• Paper filter collapsed during

brewing

• Use proper filter.

Brew basket overflowed

• Too much coffee

• Coffee ground too finely

• Double batching

• Use no more than 3 1/2 oz. of coffee.

• Coarsen grind.

• You must dump old coffee and use

fresh new filter for each brew.

Unpleasant taste

• Water tank or brew basket needs

cleaning

• Clean, sanitize (de-lime).

• Refer to Regular Maintenance

section.

Brewer will not brew

• Basket has not been changed

• Remove basket, replace filter,

reinstall.

Grinder will not start when start

button is pushed

• Main power switch turned off

• No power to outlet

• Basket out

• Circuit breaker has tripped

• Basket has not been changed

• Turn main power switch, on located

on back of unit (left side from front) on.

• Check outlet with lamp or radio to

verify outlet has power.

• Ensure basket is in position.

• Reset circuit breaker (located on

back of unit) by pushing the reset

button in until you hear a click.

• Remove basket, replace filter,

reinstall.

Grinder runs or hums but no

coffee is dispensed

• Shear disc is broken

• Obstruction in opening of auger

assembly (on dual bean units)

• Obstruction in opening to grinding

chamber

• Slide valve is bending

• Blown fuse on controller board

(Dual bean only)

• Replace shear disc. See Shear

Disc Replacement section.

• Remove hopper and clear

obstruction.

• Remove hopper and clean

obstruction.

• Check for free operation of slide valve.

Adjust solenoid mount or slide valve

mount as required. Make sure white

slide valve gasket is not touching

moving parts.

• Check for blown fuse and replace

with 5 Amp fuse.

Quantity of coffee dispensed

each throw is not the same

• Defective timer in controller

• Slide valve is binding

• Check the length of time grinder

runs with watch.

• Remove upper assembly and clean

obstruction.

• Check for free operation of slide

valve. Adjust solenoid mount or

slide valve mount as required.

Make sure white slide valve gasket

is not touching moving parts.