7 weekly exercise cycle, 2 cooling system, Every three months – Generac Power Systems 004988-4 User Manual

Page 17: Once every six months, Once annually, First 100 operating hours, Every 500 operating hours

15

3.7 WEEKLY EXERCISE CYCLE

The engine control board will start and run the gen-

erator once every seven days for approximately 12

minutes. If utility should fail during this exercise

period, the engine control board will transfer the load

to the generator output and continue to run until util-

ity returns.

On the day, and at the time of day chosen for the

generator to exercise, set the weekly exercise cycle

as follows:

1. Place the AUTO/OFF/MANUAL switch in the

AUTO position.

2. Press and hold the “Set Exercise” switch for three

seconds, then release.

At this time all five red LEDs will flash for approxi-

mately 10 seconds, then the engine will start and run

for it’s 12 minute exercise period, then shut down.

The generator will now start and run each week at

the same time.

If DC power to the control board is lost, the weekly

exercise setting will be lost. This is indicated by all

five red LEDs continually flashing. In this state the

generator will still start and run in manual mode, or

automatically start and run if UTILITY is lost while in

Auto mode, but it will not perform a weekly exercise

cycle.

If a failure occurs while running in this mode, the five

red LEDs will stop flashing, the individual fault LED

will turn on and the engine will shut down. Once the

AUTO/OFF/MANUAL switch has been switch to OFF,

the individual fault LED will turn OFF and the five

red LEDs will begin flashing to show exercise has still

not been set.

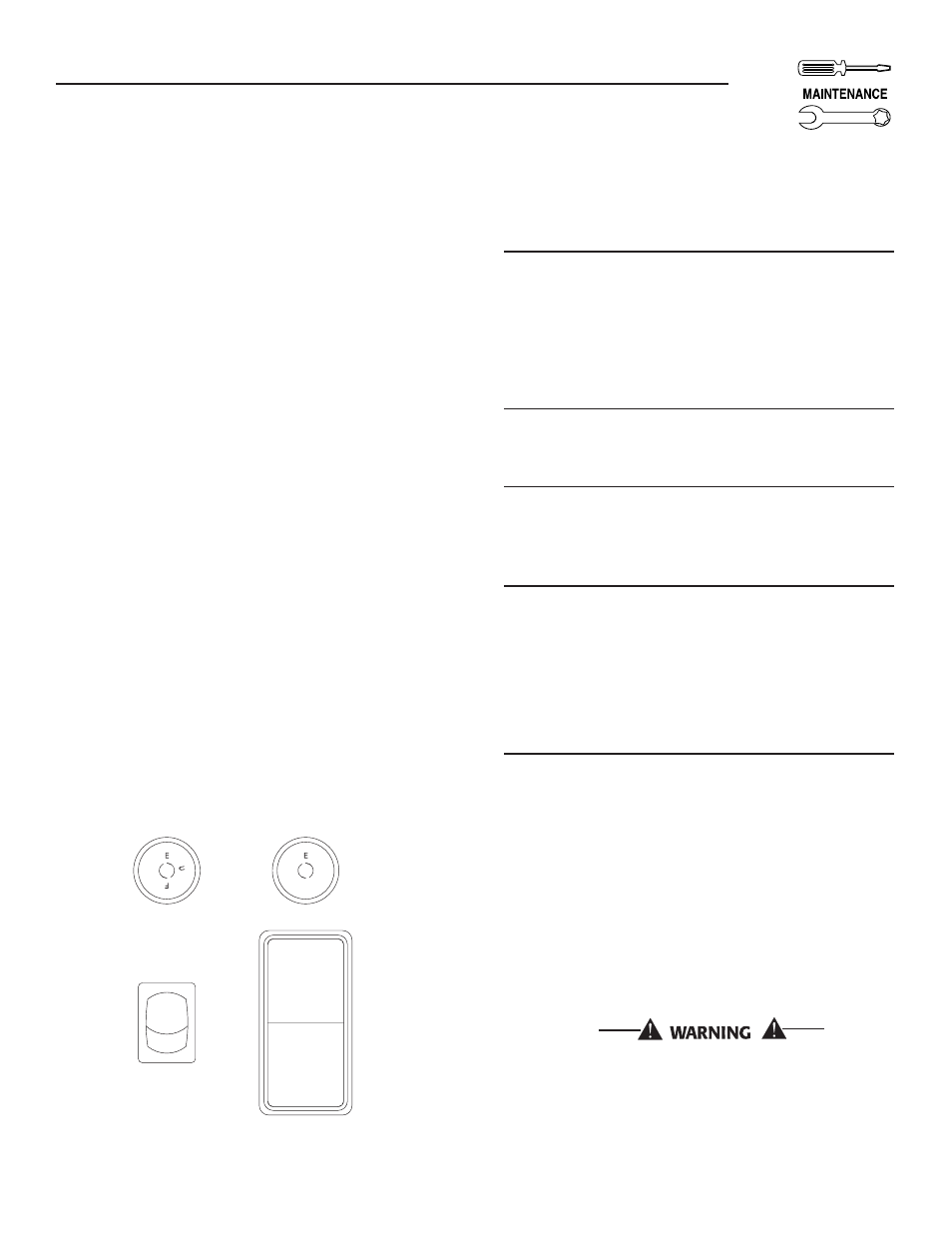

Figure 3.2 - “Set Exercise” Switch

E

E

US

F

F

S

US

E

E

US

F

F

U

S

FU

S

BAT.

FUSE

CHARGER

ON

OFF

EXERCISE

TIME

SET

4A

MANUAL

AUTO

OFF

FUSE

15A

MAIN

4.1

MAINTENANCE PERFORMED BY

AUTHORIZED SERVICE FACILITIES

EVERY THREE MONTHS

1. Check battery state of charge and condition.

2. Inspect and test fuel system.

3. Check

transfer

switch.

4. Inspect

exhaust

system.

5. Check engine ignition system.

6. Check

fan

belts.

ONCE EVERY SIX MONTHS

1. Test Engine Safety Devices (low oil pressure, low

coolant level, high coolant temperature).

ONCE ANNUALLY

1. Test engine governor. Adjust or repair, if needed.

2. Clean,

inspect

generator.

3. Flush

cooling

system.

FIRST 100 OPERATING HOURS

1. Change engine oil and oil filter. (After initial

change, service engine oil and filter at 150 operat-

ing hours or 6 months, whichever comes first.)

2. Retorque cylinder head. (See Torque Specs,

Section 1.13.)

3. Retorque intake and exhaust manifold. (See

Torque Specs, Section 1.13.)

EVERY 500 OPERATING HOURS

1. Service

air

cleaner.

2. Check

starter.

3. Check engine DC alternator.

4.2 COOLING

SYSTEM

Air intake and outlet openings in the generator com-

partment must be open and unobstructed for contin-

ued proper operation. This includes such obstruc-

tions as high grass, weeds, brush, leaves and snow.

Without sufficient cooling and ventilating air flow, the

engine/generator quickly overheats, which causes it

to shut down. (See Section 6 for installation drawings

and vent locations.)

The exhaust system parts from this product get

extremely hot and remain hot after shutdown.

High grass, weeds, brush, leaves, etc. must

remain clear of the exhaust. Such materials may

ignite and burn from the heat of the exhaust

system.

Section 4 — Maintenance

Liquid-cooled 30 kW Generators