Routine maintenance, Motors, Shaft bearings – Greenheck Fan Fiberglass Centrifugal Fan 474051 User Manual

Page 9

9

Model BCSW-FRP

Routine Maintenance

Once the unit has been put into operation, a routine

maintenance schedule should be set up to accomplish

the following:

1. Lubrication of bearings and motor (see below).

2. Wheel, housing, bolts and set screws on the entire

fan should be checked for tightness.

3. Any dirt accumulation on the wheel or in the

housing should be removed to prevent unbalance

and possible damage.

4. Springs should be checked for breaks and

fatigue. Rubber isolators should be checked for

deterioration.

5. Inspect fan impeller and housing looking for fatigue,

corrosion, or wear.

When performing any service to the fan, disconnect

the electrical supply and secure fan impeller.

Motors

Motor maintenance is generally limited to cleaning

and lubrication. Cleaning should be limited to exterior

surfaces only. Removing dust and grease build up on

the motor housing assists proper motor cooling. Never

wash-down motor with high pressure spray. Greasing

of motors is only intended when fittings are provided.

Many fractional motors are permanently lubricated for

life and require no further lubrication. Motors supplied

with grease fittings should be greased in accordance

with the manufacturer’s recommendations. When

motor ambient temperature does not exceed 104°F

(40°C), the grease should be replaced after 2000 hours

of running time.

CAUTION

When operating conditions of the fan are to be

changed (speed, pressure, temperature, etc.),

consult Greenheck to determine if the unit can

operate safely at the new conditions.

Shaft Bearings

The bearings for Greenheck fans are carefully

selected to match the maximum load and operating

conditions of the specific class, arrangement, and

fan size. The instructions provided in this manual

and those provided by the bearing manufacturer, will

minimize any bearing problems. Bearings are the

most critical moving part of the fan, therefore special

care is required when mounting them on the unit and

maintaining them.

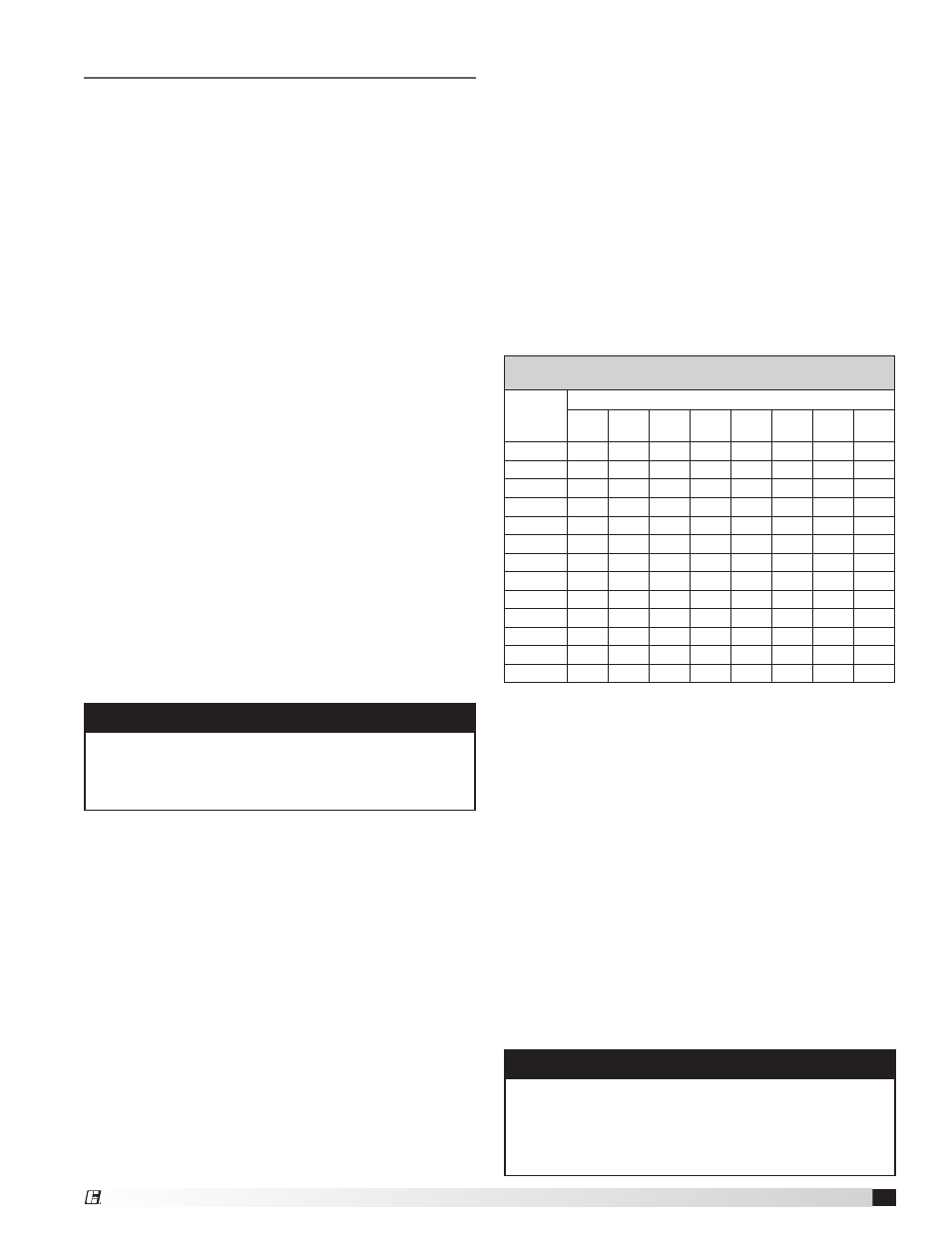

Refer to the following chart and the manufacturers

instructions for grease types and intervals for various

operating conditions. Never mix greases made with

different bases. This will cause a breakdown of the

grease and possible failure of the bearing.

WARNING

Lubricate bearings prior to periods of extended

shutdowns or storage and rotate shaft monthly to

aid in preventing corrosion. If the fan is stored more

than three months, the bearings should be purged

with new grease prior to start-up.

Recommended Fan Bearing Lubrication Schedule - Standard Grease

Lubrication Schedule in Months*

Fan RPM

Bearing Bore (inches)

1

⁄

2

-

1

1

1

⁄

8

-

1

1

⁄

2

1

5

⁄

8

-

1

7

⁄

8

1

15

⁄

16

-

2

3

⁄

16

2

7

⁄

16

- 3

3

3

⁄

16

-

3

1

⁄

2

3

15

⁄

16

-

4

1

⁄

2

4

15

⁄

16

-

5

7

⁄

8

To 250

12

12

12

12

12

12

10

8

500

12

12

10

10

8

7

5

4

750

12

9

8

7

6

4

3

2

1000

12

7

6

5

4

3

2

1

1250

12

6

5

4

3

2

1

0.5

1500

12

5

4

3

2

1

0.5

2000

12

3

2

2

1

0.5

0.25

2500

12

2

2

1

0.5

0.25

3000

12

2

1

0.5

0.25

3500

12

1

0.5

0.25

4000

12

0.5

0.25

5000

12

0.25

# of shots**

4

8

8

10

16

25

41

57

*Suggested initial greasing interval is based on 12 hour per

day operation and 160ºF maximum housing temperature.

For continuous (24 hour) operation, decrease greasing

interval by 50%.

• If possible, relubricate with grease while in operation

without endangering personnel.

• For ball bearings (operating) relubricate until clean

grease is seen purging at the seals. Be careful not to

unseat the seal by over lubricating.

• For ball bearings (idle) add 1-2 shots of grease up to

2 in. bore sizes, and 4-5 shots of grease above 2 in. bore

sizes with hand grease gun.

• For roller bearings, relubricate with 4 shots of grease up

to 2 in. bore size, 8 shots for 2-5 in. bore size, and 16

shots above 5 in. bore size with hand grease gun.

• Adjust lubrication frequency based on condition of

purged grease.

• A high quality lithium base grease conforming to NLGI

Grade 2 consistency is recommended.

• The use of synthetic lubricants will increase lubrication

intervals by approximately three (3) times.