GSW WATER HEATING User Manual

Page 5

- 5 -

IV) OPERATION

1. Follow boiler or heat source installation and operating

instructions.

2. Fill the tank (see “FILLING” section).

3. The boiler or water heating source should be set to pro-

vide at least 11°C (20°F) higher water temperature than

the temperature setting of the storage tank

4. Turn power on, check for proper operation of boiler and

storage tank.

Temperature Adjustment

The setting of 49°C (120°F) has been proven to be satis-

factory from the standpoint of operational costs and safety.

We recommend the thermostats remain set at 49°C

(120°F).

If water temperature adjustment is required:

1. Turn "OFF" the electrical supply to the tank.

2. Remove lower access door.

3. Turn back insulation.

4. Adjust thermostat to water temperature desired.

5. Replace insulation and access door.

6. Turn "ON" the electrical supply to the tank.

V) MAINTENANCE

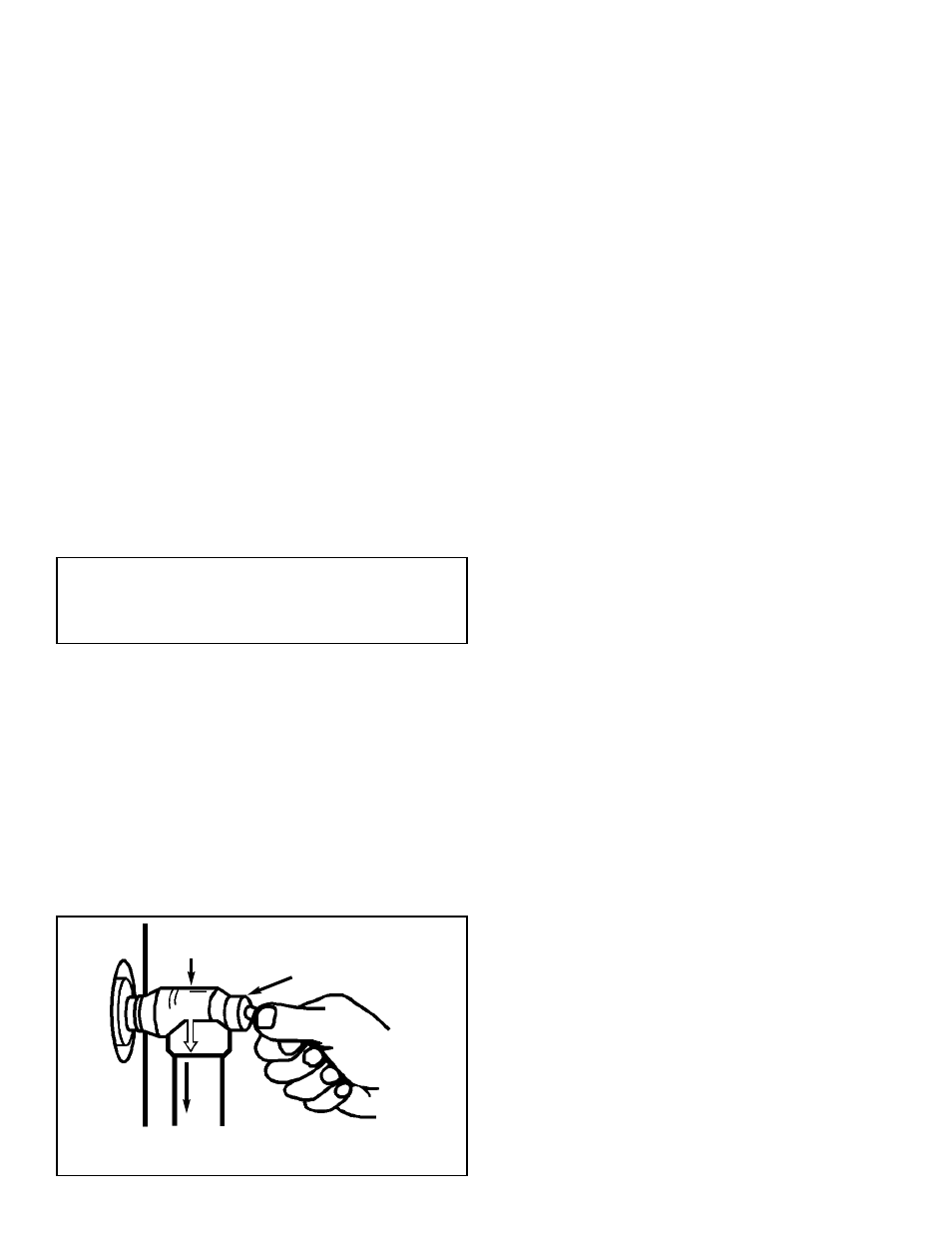

T&P Valve Check

Do not attempt to operate this storage tank with the cold

water inlet valve closed. The Temperature and Pressure

Relief Valve must be manually operated at least once a

year. This involves opening the valve to check that it is flow-

ing freely and that there are no blockages. WARNING!

WATER MAY BE HOT

and water flow can be forceful.

Caution should be taken to ensure that:

1. No one is in front of or around the outlet of the T&P

valve discharge line.

2. The water manually discharged will not cause any bod-

ily injury or property damage. The water may be

extremely hot.

While standing clear of the outlet (discharge water may be

hot), lift the lever and let it snap shut. The water should stop

immediately. If it fails to reset completely and continues to

release water, the valve is not functioning properly and must

be replaced immediately. Close the cold water supply valve,

drain the tank as directed in the “Draining and Flushing”

section, and replace the T&P valve with a new one. Failure

to install and maintain an approved T&P valve will release

the manufacturer from any claim that might result from

excessive temperature or pressure. In systems where the

relief valve discharges periodically, this may be due to ther-

mal expansion or to a thermostat that is operating at too

high a temperature. If you suspect a malfunctioning thermo-

stat, contact a qualified service technician for repairs.

Draining and Flushing

Some service work to be performed on the tank requires the

tank to be drained. It is also recommended that the tank be

drained and flushed every 6 months to remove any sedi-

ment and lime which may build up in the bottom of the tank

during operation. Such buildup can result in noisy operation.

To drain the tank:

1. Turn "OFF" the electrical supply to the tank.

2. Close the cold water supply valve.

3. Open a nearby hot water faucet served by the system.

4. Connect a hose to the drain valve and route it to an ade-

quate drain.

CAUTION!

The water being drained can be extremely

hot! The drain hose should be rated for at least 93°C

(200°F). If the drain hose does not have this rating, open the

cold water supply valve and a nearby hot water faucet

served by the system until the water flow is no longer hot.

Close the cold water supply valve and resume.

5. Open the drain valve and allow all the water to drain

from the tank.

6. Open the cold water supply valve and flush the tank as

needed to remove sediment and any other foreign mat-

ter that may have entered the system. Close the cold

water supply valve when clean water flows.

7. Perform any other servicing as required.

8. Close the drain valve, disconnect hose and refill the

tank (see “FILLING” section).

9. Turn "ON" the electrical supply to the tank.

Cathodic Protection

Your storage booster tank has been equipped with one or

more anodes that protect the tank from corrosion. Over

time, as the anode works, it slowly dissolves and must be

replaced. If the anode(s) is less than 10mm (3/8 in.) in diam-

eter, or has any of the inner steel core exposed, it must be

replaced. Depending on water conditions, an anode can last

from one to ten years. Many localities treat their water and

this can have a significant effect on the life of your heater.

Water conditioning, such as over-softening, can accelerate

the rate at which the anode(s) is consumed. Rapid depletion

can leave a heater unprotected causing a premature failure.

It is good practice to check the anode(s) annually to see if it

needs replacing. Operating a storage tank without an

actively working anode(s) will void the warranty. Failure to

maintain the anode may result in premature failure of the

storage tank due to corrosion and leaks.

CAUTION

The out-flowing water is hot. Avoid splashing the water on

yourself or on the surroundings where it may cause dam-

age.

Figure 5: T&P Valve Test

Temperature and Pressure

Relief Valve

Manual Relief Valve

Discharge line to drain