Piping c, Caution – Goodman Mfg IO - 395 User Manual

Page 6

6

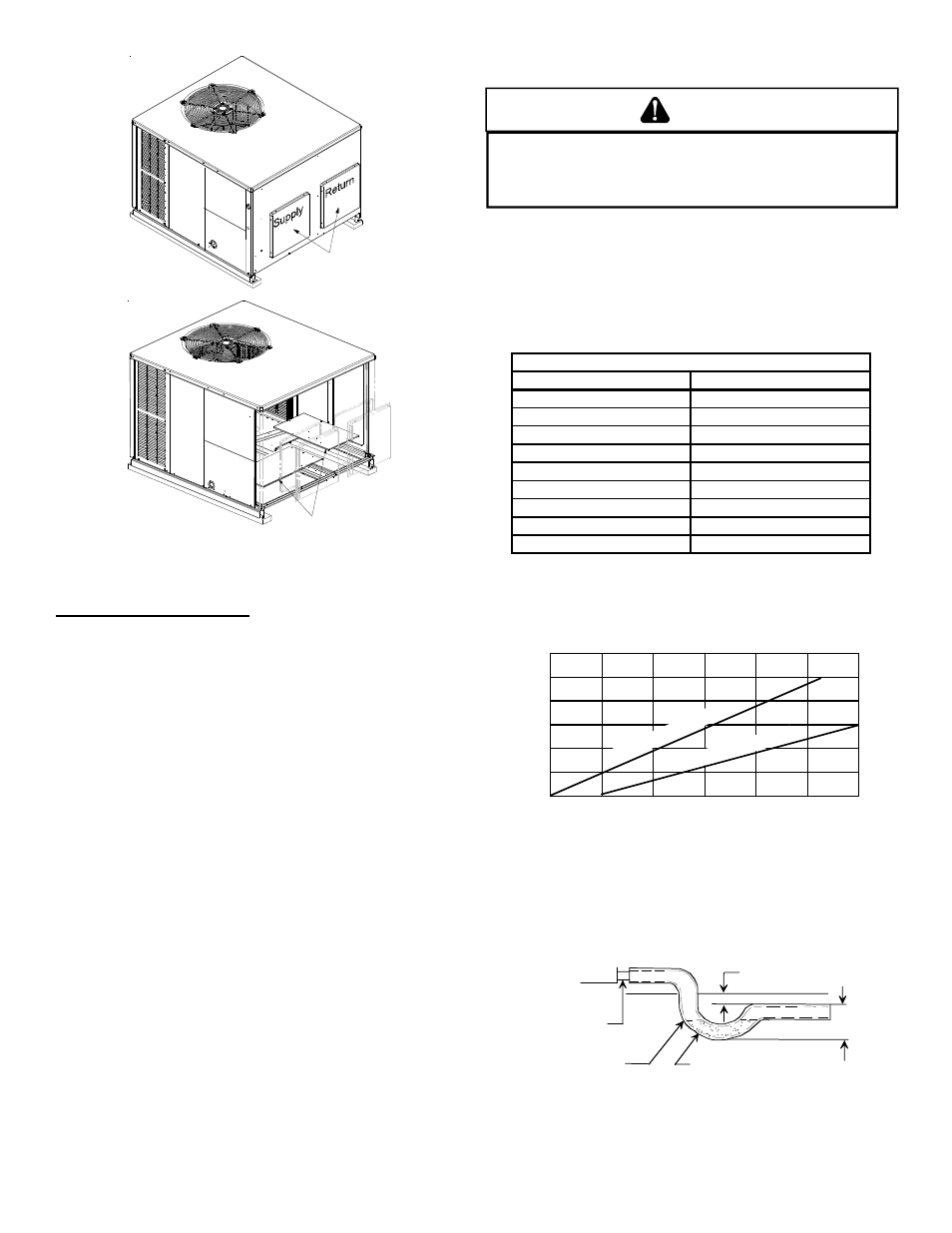

Remove these covers

for horizontal duct

applications

Remove these panels

for downflow duct

applications

Supply

Return

Duct Cover Installation

Down Discharge Applications

Cut insulation around bottom openings and remove panels from

the bottom of the unit, saving the screws holding the panels in

place.

NOTE: Single phase models require installation of horizontal duct

kit #20464501PDGK (medium chassis) and #20464502PDGK

(large chassis).

D

UCT

WORK

Duct systems and register sizes must be properly designed for

the C.F.M. and external static pressure rating of the unit. Duct work

should be designed in accordance with the recommended methods

of Air Conditioning Contractors of America Manual D (Residential)

or Manual Q (Commercial). All ductwork exposed to the outdoors

must include a weatherproof barrier and adequate insulation.

A duct system should be installed in accordance with Standards of

the National Board of Fire Underwriters for the Installation of Air

Conditioning, Warm Air Heating and Ventilating Systems. Pamphlets

No. 90A and 90B.

The supply duct from the unit through a wall may be installed

without clearance. However, minimum unit clearances as shown

in the appendix must be maintained. The supply duct should be

provided with an access panel large enough to inspect the air

chamber downstream of the heat exchanger. A cover should be

tightly attached to prevent air leaks.

For duct flange dimensions on the unit refer to the Unit Dimension

illustration in the appendix.

For down-discharge applications, the ductwork should be attached

to the roof curb prior to installing the unit. Duct work dimensions are

shown in the roof curb installation manual.

If desired, supply and return duct connections to the unit may be

made with flexible connections to reduce possible unit operating

sound transmission.

F

ILTERS

CAUTION

T

O PREVENT PROPERTY DAMAGE DUE TO FIRE AND LOSS OF

EQUIPMENT EFFICIENCY OR EQUIPMENT DAMAGE DUE TO DUST AND LINT

BUILD UP ON INTERNAL PARTS, NEVER OPERATE UNIT WITHOUT AN AIR

FILTER INSTALLED IN THE RETURN AIR SYSTEM.

Filters are not provided with unit and must be supplied and exter-

nally installed in the return duct system by the installer. An optional

factory approved internal filter rack may also be used. A field-in-

stalled filter grille is recommended for easy and convenient ac-

cess to the filters for periodic inspection and cleaning. When

installing filters, ensure the air flow arrows on the filter are pointing

toward the circulator blower.

Refer to the unit filter size chart below for filter size information.

NOMINAL SIZE (INCHES)

NOMINAL AREA (SQ. FT.)

10x20

1.4

14x20

1.9

14x25

2.4

15x20

2.1

16x20

2.2

16x25

2.8

20x20

2.8

20x25

3.5

25x25

4.3

MINIMUM FILTER SIZE

NOTE: Filters must have adequate face area for the rated quantity

of the unit. See the air delivery table below for recommended filter

size. Size the filters in accordance with their manufacturer recom-

mendations. Throwaway filters must be sized for a maximum face

velocity of 300 feet per minute.

500 1000 1500 2000 2500 3000 3500

7

6

5

4

3

2

DIS

PO

SA

BL

E F

ILT

ER

PER

MAN

ENT

FIL

TER

Airflow - SCFM

N

o

m

in

a

l

F

ilt

e

r

A

re

a

S

q

u

a

re

F

e

e

t

PIPING

C

ONDENSATE

D

RAIN

The condensate drain connection of the evaporator is a half cou-

pling of ¾” N.P.T. A trap must be provided to have Proper conden-

sate drainage.

2" Minimum

3" Minimum

A Positive Liquid Seal

Is Required

Flexible

Tubing-Hose

Or Pipe

Drain

Connection

Unit

Install condensate drain trap as shown. Use ¾ “ drain connection

size or larger. Do not operate without trap. Unit must be level or

slightly inclined toward drain.