Operation, Air source, Maintenance – Global Machinery Company ATBR1650-3PK User Manual

Page 45

15

2. Connect the Framing Gun to an air supply and fire a nail

into a sample piece of wood to determine the driving

depth has been achieved.

3. If the nail depth is not acceptable, disconnect the tool

from the air supply and re-adjust.

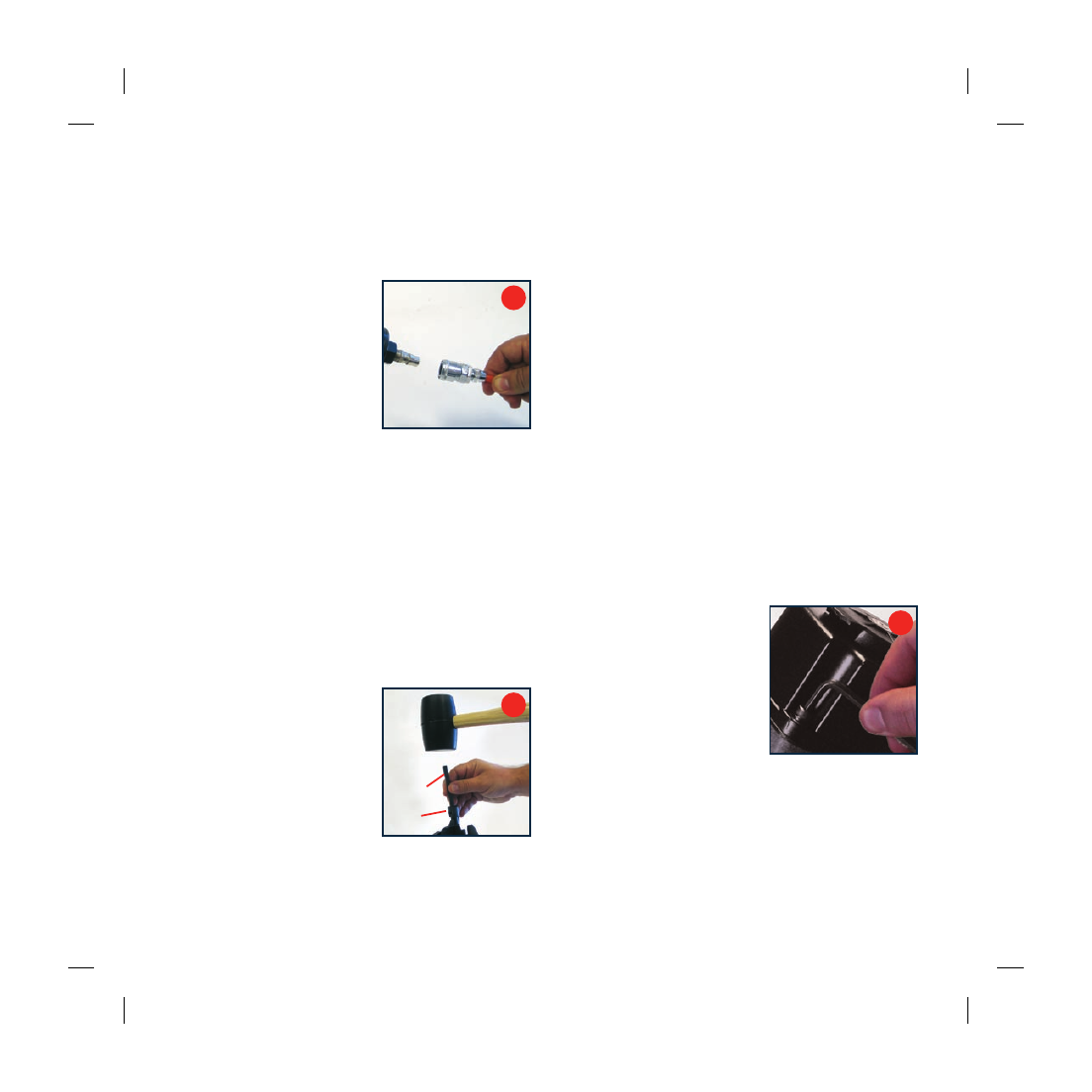

Connecting the air hose

1. Slip the air coupling of the air

hose onto the air fitting on

the nailer. Be sure that the

air coupling locks firmly into

position when installed onto

the air fitting (Fig. D).

2. A hose coupling must be

installed on or near the tool in

such a way that the pressure reservoir will discharge at

the time the air supply coupling is disconnected.

Operation

1. Push the contact safety nose (1) against the work surface

without depressing the trigger (4).

2. Once the nail gun has been positioned to the appropriate

firing angle, depress the trigger (4) and release.

Clearing a jam

CAUTION.

Always disconnect the hose and remove the

nails from the magazine before clearing a jam. When the

nailer becomes jammed, proceed as follows:

1. Insert a small rod or the like

into the ejection port and tap it

with a hammer to drive out the

nail jamming the ejection port.

(Fig. E)

2. Reset the nails inside the

magazine

3. Test the framing gun.

Air source

This tool is designed to operate on clean, dry, compressed

air at regulated pressures between 75 and 120 PSI.

The preferred system would include a filter, a pressure

regulator, and an automatic oiler located as close to the

tool as possible.

All compressed air contains moisture and other

contaminates that are detrimental to internal components

of the tool. An air line filter will remove most of these

contaminates and significantly prolong the life of the tool.

If an in-line oiler is not available, place 3 - 4 drops of non

detergent oil into the tool’s air inlet at the beginning of

each workday.

DANGER

. All air line components (hoses, connectors,

filters, regulators, etc.) must have a minimum working

pressure rating of at least 150 PSI or 150% of maximum

system potential, whichever is greater.

Maintenance

CAUTION.

Always ensure that the air hose is disconnected

from the tool before attempting to perform inspection or

maintenance.

Maintenance of nailer

Always check the tool for its

overall condition and loose

screws before operation.

Tighten as required (Fig. F).

1. Make sure all safety systems

are in working order before

operation. The tool must not

operate if only the trigger is

pulled or if only the contact safety nose (1) is pressed

against the wood. It must work only when both actions

are performed. Test for possible faulty operation with

nails unloaded.

2. Entering dirt or foreign matter into the tool may cause

damage to the tool.

3. When not in use, disconnect the air hose.

D

E

Small rod

Ejection port

F