7 engine governor adjustment, 8 voltage regulator adjustment – Guardian Technologies 04456-2 User Manual

Page 15

Generac

®

Power Systems, Inc.

13

Section 2 — Post Installation Start-up and Adjustments

Guardian Air-cooled 7 kW, 12 kW and 15 kW Generators

If this procedure or the equipment are not available,

locate the nearest Generac Guardian Dealer and they

can perform the adjustments.

NOTE:

A service fee may be charged for this adjustment.

2.7

ENGINE GOVERNOR ADJUSTMENT

If both AC frequency and voltage are correspondingly

high or low, adjust the engine governor as follows:

2.7.1

7 KW UNITS

1. Loosen the governor clamp bolt (Figures 2.3).

2. Hold the governor lever at its wide open throttle

position, and rotate the governor shaft clockwise

as far as it will go. Then, tighten the governor

lever clamp bolt to 70 inch-pounds (8 N-m).

3. Start the generator; let it stabilize and warm up

at no-load.

4. Connect a frequency meter across the generators

AC output leads.

5. Turn the speed adjust nut to obtain a frequency

reading of 63 Hertz.

6. When frequency is correct at no load, check the

AC voltage reading. If voltage is incorrect, the volt-

age regulator may require adjustment.

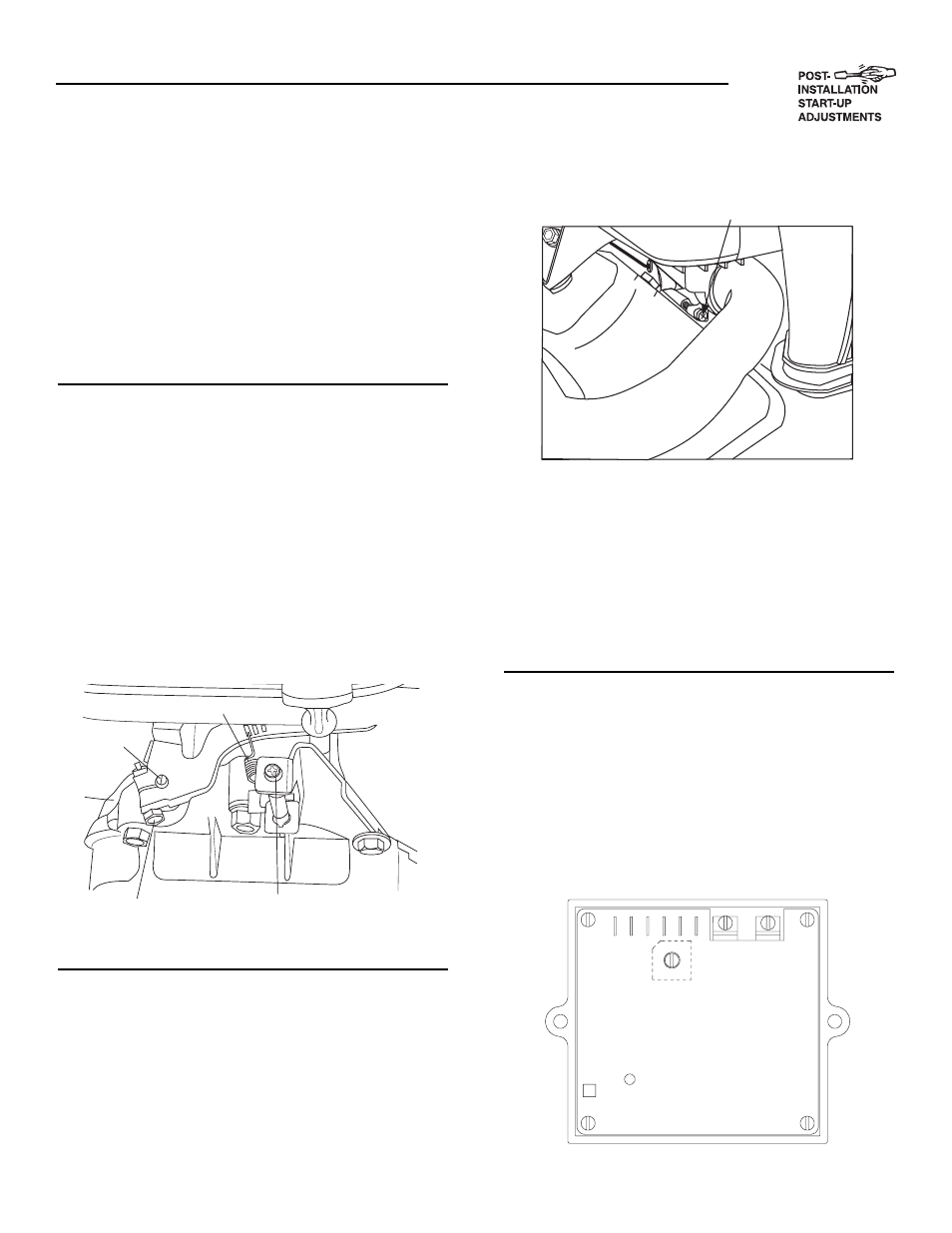

Figure 2.3 — Engine Governor Adjustment

2.7.2

12 KW AND 15 KW UNITS

1. Loosen governor clamp bolt (See Figure 2.3).

2. Completely remove the idle spring.

3. With governor arm at wide open throttle position,

rotate governor shaft fully clockwise. Tighten

clamp bolt to 84 inch-pounds.

4. Start unit and apply full load. Use full load speed

adjust screw (Figure 2.4) to adjust frequency to

58 Hz.

5. Remove load, stop engine, loosen the idle adjust

screw and reconnect the idle spring.

Figure 2.4 — Full Load Speed Adjust Screw

6. Using a hand, push the governor arm to the

closed throttle position. Make sure the idle spring

does not stretch at all.

7. Restart the unit.

8. Slowly turn the idle adjust screw to adjust the no-

load idle frequency to 63-63.5 Hz (with door

open).

9. The governor is now set.

2.7.3

ADDITIONAL CORROSION

PROTECTION

Periodically spray all engine linkage parts and brack-

ets with corrosion inhibiting spray such as WD-40 or

a comparable product.

2.8

VOLTAGE REGULATOR

ADJUSTMENT

With the frequency between 62-63 Hertz, slowly turn

the slotted potentiometer (Figure 2.5) until line volt-

age reads 247-252 volts.

Figure 2.5 – Voltage Adjustment Potentiometer

◆

Full Load Speed Adjust Screw

◆

Governor Clamp Bolt

Governor

Shaft

(Rotate

Clockwise)

Idle Spring

No Load Idle

Adjustment Screw

◆