Global Machinery Company POL1450M User Manual

Page 13

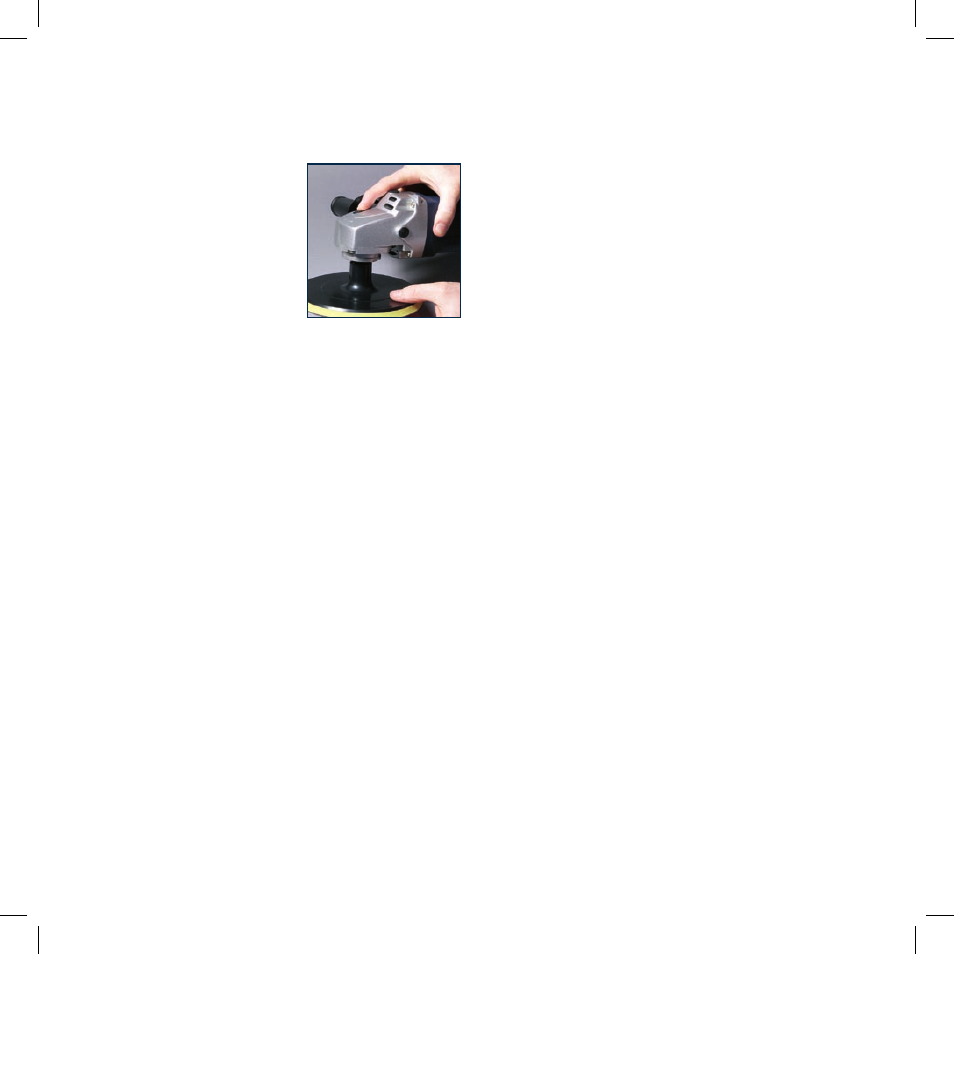

Replacing the rubber disc

Switch off the grinder/sander/polisher and disconnect it from

the power supply.

1. The polishing sponge and

rubber disc are fitted with a

quick disc release system

meaning that no tools are

required. To remove the disc,

press and hold the spindle

lock button (2) and unscrew

the disc from the spindle. Note

that the disc unscrews in an

anti-clockwise direction.

2. Remove the disc.

3. Check the new disc.

4. Fit the new disc onto the spindle and screw it on in a

clockwise direction. Turn the new disc by hand, ensuring

that it is tight on the spindle and that it rotates fully and

does not wobble unduly.

5. Run the grinder/sander/polisher at no load for at least

one minute to ensure the new disc is in good condition.

Make sure you are wearing all the safety gear and that

you face the polisher away from you.

Maintenance

All the bearings are sealed ball bearings, lubricated for life,

and require no maintenance.

Power cord maintenance

If the supply cord needs replacing, the task must be carried

out by the manufacturer, the manufacturer's agent, or an

authorised service centre in order to avoid a safety hazard.

Cleaning

1. Keep the tool’s air vents unclogged and clean at all

times.

2. Remove dust and dirt regularly. Cleaning is best done

with a rag. Wear safety goggles or an eye shield and

gloves whist cleaning.

3. Re-lubricate all moving parts at regular intervals.

4. Never use caustic agents to clean plastic parts.

CAUTION.

Do not use cleaning agents to clean the plastic

parts of the tool. A mild detergent on a damp cloth is

recommended. Water must never come into contact with

the tool.

General inspection

Regularly check that all the fixing screws are tight.

They may vibrate loose over time.

13