Initial certification, Re-certification – Gentek 3940302 User Manual

Page 64

59

Chapter 6: Maintaining Your Filtered Enclosure

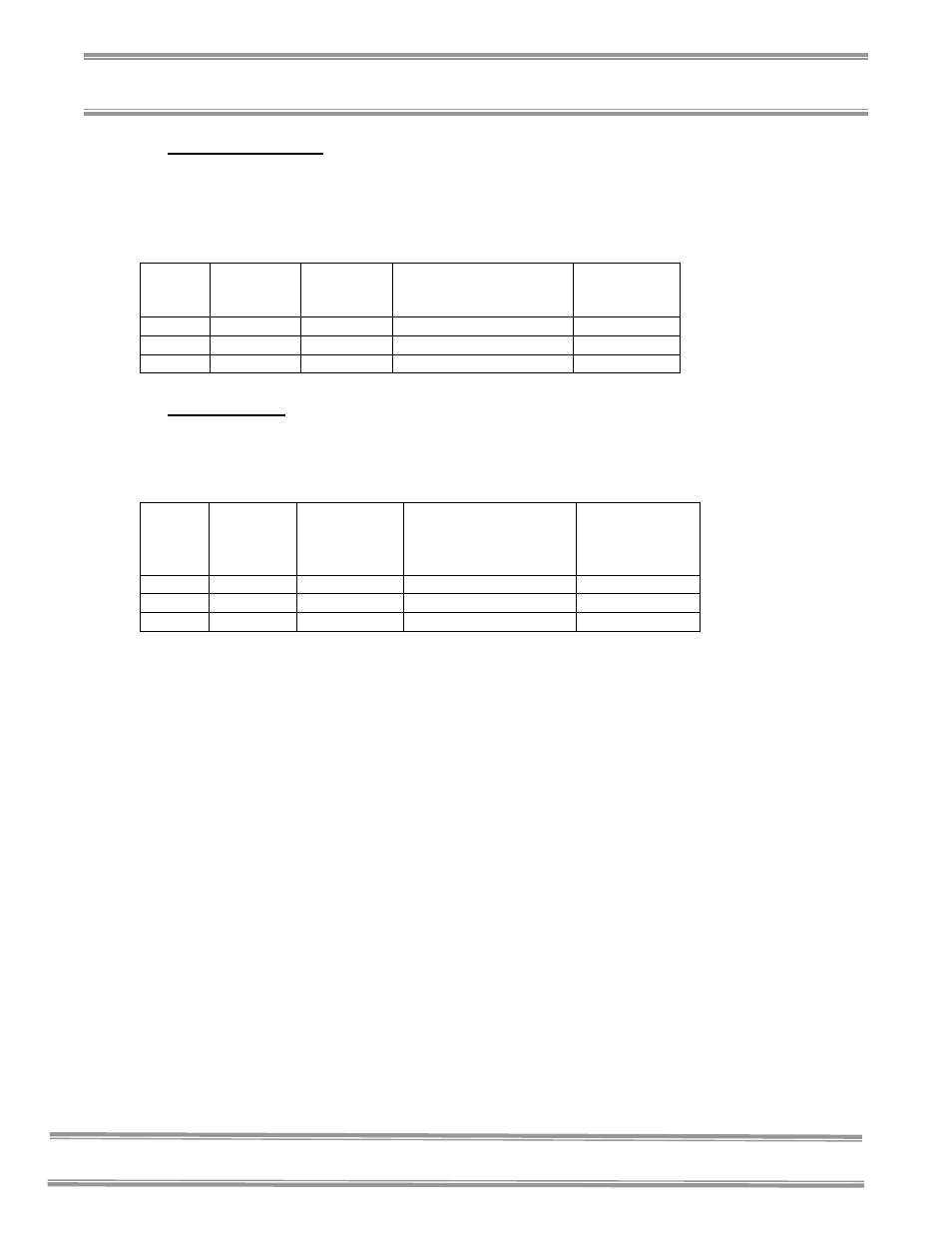

Formaldehyde only

For formaldehyde, use 10% of the impregnated carbon weight.

Formalin is 37% formaldehyde by weight. The density of formalin

is 1.08 g/ml.

Model

Size Filter

Size

Pounds of

Formasorb

Carbon

Adsorbed weight of

Formaldehyde

Adsorption

Volume of

Formalin

2'

18 x 18 x 1

7.0

0.7 lbs./318g

796 ml

3'

30 x 18 x 1

12.0

1.2 lbs./545g

1364 ml

4'

42 x 18 x 1

16.8

1.68 lbs./763g

1910 ml

Ammonia only

For ammonia, use 10% of the impregnated carbon weight. Assume

use of a 50% solution of ammonia for these calculations.

Model

Size

Filter Size

Pounds of

Ammonasorb

II Carbon

Adsorbed weight of

Ammonia

Adsorbed

Volume of 50%

Ammonia

Solution

2'

18 x 18 x 1

9.2

0.92 lbs./418g

836 ml

3'

30 x 18 x 1

13.5

1.35 lbs./613g

1226 ml

4'

42 x 18 x 1

18.9

1.89 lbs./859g

1718 ml

Initial Certification

The filtered enclosure has been certified at the factory for an

inflow velocity of 90±10 fpm along with the HEPA Filter Leak

Test. The filtered enclosure should be certified for the proper

inflow velocity required by your Safety Officer. It is also a

conservative recommendation to perform the HEPA Filter Leak

Test again should there be any damage caused during transport.

Re-Certification

Under normal operating conditions, the enclosure should be

recertified at least annually if serviced. The certifier should

perform the following tests.

•

Inflow Velocity Test

•

HEPA Filter Leak Test

In addition, the following tests should also be performed at the

user’s discretion: