Jam proof system operation, Oiling shredder, Safesense – FELLOWES SB-125Ci User Manual

Page 4: Technology operation, Sleep mode, Continue 100% jam proof shredding

3

Eliminates frustrating jams by preventing overloads and powering through misfed paper.

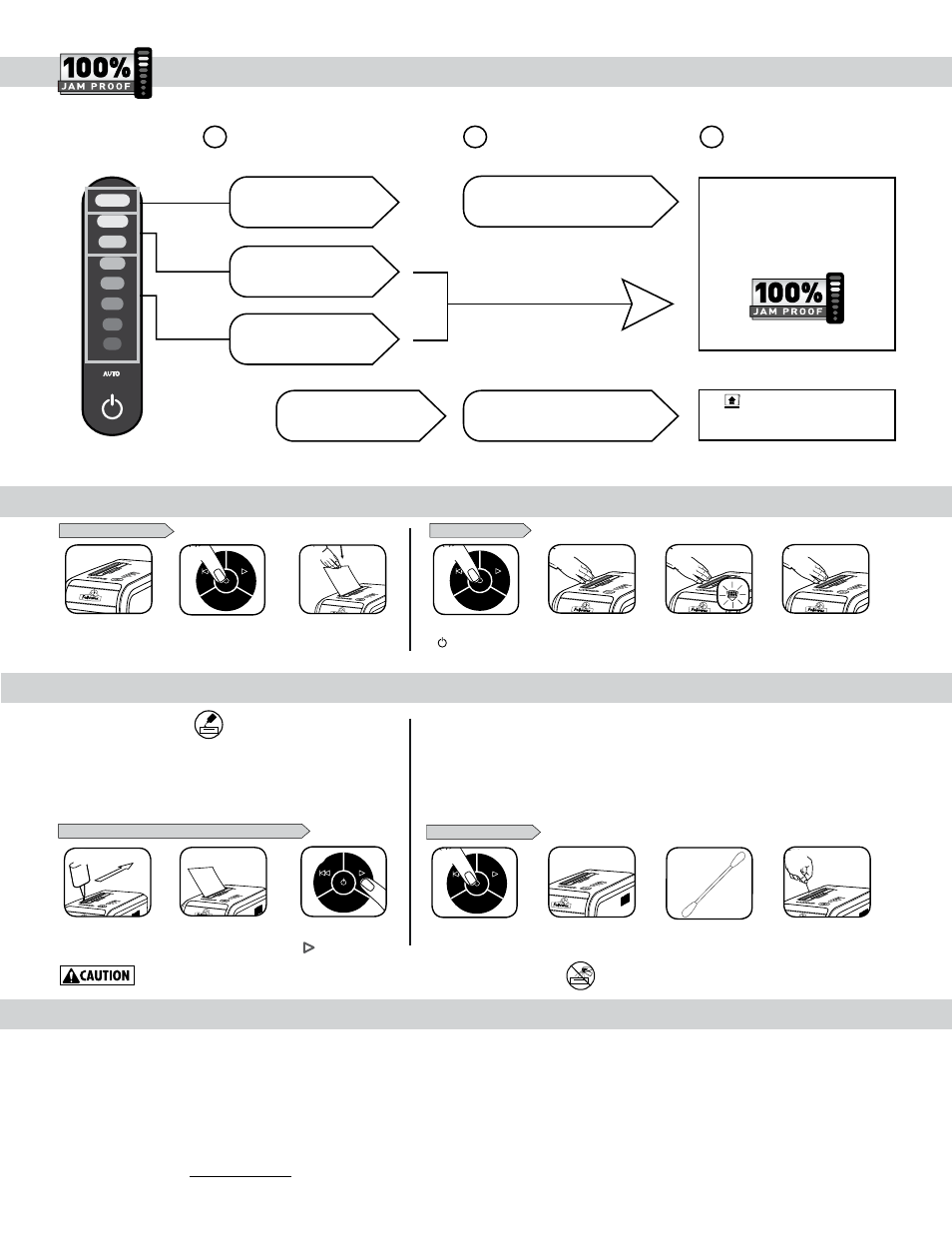

JAM PROOF SYSTEM OPERATION*

*100% Jam Proof when used in accordance with user manual

PREvENTIvE MAINTENANCE AND MISCELLANEOUS TROUBLESHOOTING

• Self Cleaning Cycle: Shredder periodically cycles in forward and reverse lasting 3-6 seconds (SB-125Ci).

• Empty wastebasket when bin full indicator lights up.

• Shredder won’t run if the door is open, or bin needs to be emptied.

• Maintenance is an important part of protecting your investment. Don’t forget our oil (35250) and shredder bags (36054).

• When shredding for a prolonged period of time, the motor can become warm and require a cool down period. When this occurs the overheat indicator will alert you to the problem.

This model will require 45 minutes to cool down.

Go to Support Section at www.fellowes.com or see back page of manual for useful telephone numbers.

Advanced Jam Prevention- Electronically

measures paper thickness to prevent paper jams:

Remove several sheets until

indicator is below red.

Continue 100% Jam

Proof Shredding

If a misfeed

occurs:

If

illuminates after paper has been

reversed, press reverse and remove paper.

Otherwise, regular shredding will resume.

1

2

3

Up to RED: Too many

sheets have been inserted.

Up to GREEN: More sheets

can be added.

Up to YELLOW: Productivity

is optimized.

All indicators light up and

shredder pauses for 3-6 seconds

Wait for flashing to stop after automatic correction

is complete. Regular shredding will resume.

TO CLEAN THE SENSORS

CLEANING AUTO-START INFRARED SENSORS

BASIC PRODUCT MAINTENANCE AND TROUBLESHOOTING

Paper detection sensors are designed for maintenance free operation. However, on rare occasions the sensors

may become blocked by paper dust causing the motor to run even if there is no paper present

(Note: two paper detection sensors are located in the center of the paper entry)

.

All cross-cut shredders require oil for peak performance. If not oiled, a

machine may experience diminished sheet capacity, intrusive noise when

shredding and could ultimately stop running. To avoid these problems, we

recommend you oil your shredder each time you empty your waste bin.

OILING SHREDDER

15

15

*Only use a non-aerosol vegetable oil in long nozzle container such as Fellowes 35250

FOLLOW OILING PROCEDURE BELOW AND REPEAT TWICE

Turn off and unplug

shredder

Locate Auto-start

infared sensor

Using cotton swab, wipe

away any contamination

from the paper sensors

Dip cotton swab in

rubbing alcohol

Shred one sheet

Press and hold forward

( ) 2-3 seconds

*Apply oil across entry

SAFESENSE

®

TECHNOLOGY OPERATION

WHEN IN SLEEP MODE

SLEEP MODE

In sleep mode

To get out of sleep mode

touch control panel

insert paper

or

SET-UP AND TESTING

Turn the shredder ON

( ) to activate SafeSense

®

Touch test area and

look for the SafeSense

®

indicator to illuminate

SafeSense

®

is active and

working properly

If hand is held on SafeSense

®

area more than 2 seconds

shredder will shut off

3

AUTO

AUTO

AUTO

1

2

4

2

AUTO

AUTO

AUTO

3

1

AUTO

1

2

3

AUTO

1

2

4

3