Festool TDK 12 User Manual

Page 4

4

Wall mounting LC 45

The charger LC 45 has two longitudinal slots on

its rear by which it can be suspended on walls

using two screws (e.g. button-headed or flat head

screw with a shaft diameter of 5 mm). Screw

both screws into the wall 96 mm apart until the

screwhead is protruding from the wall by approx.

4 mm.

Machine settings

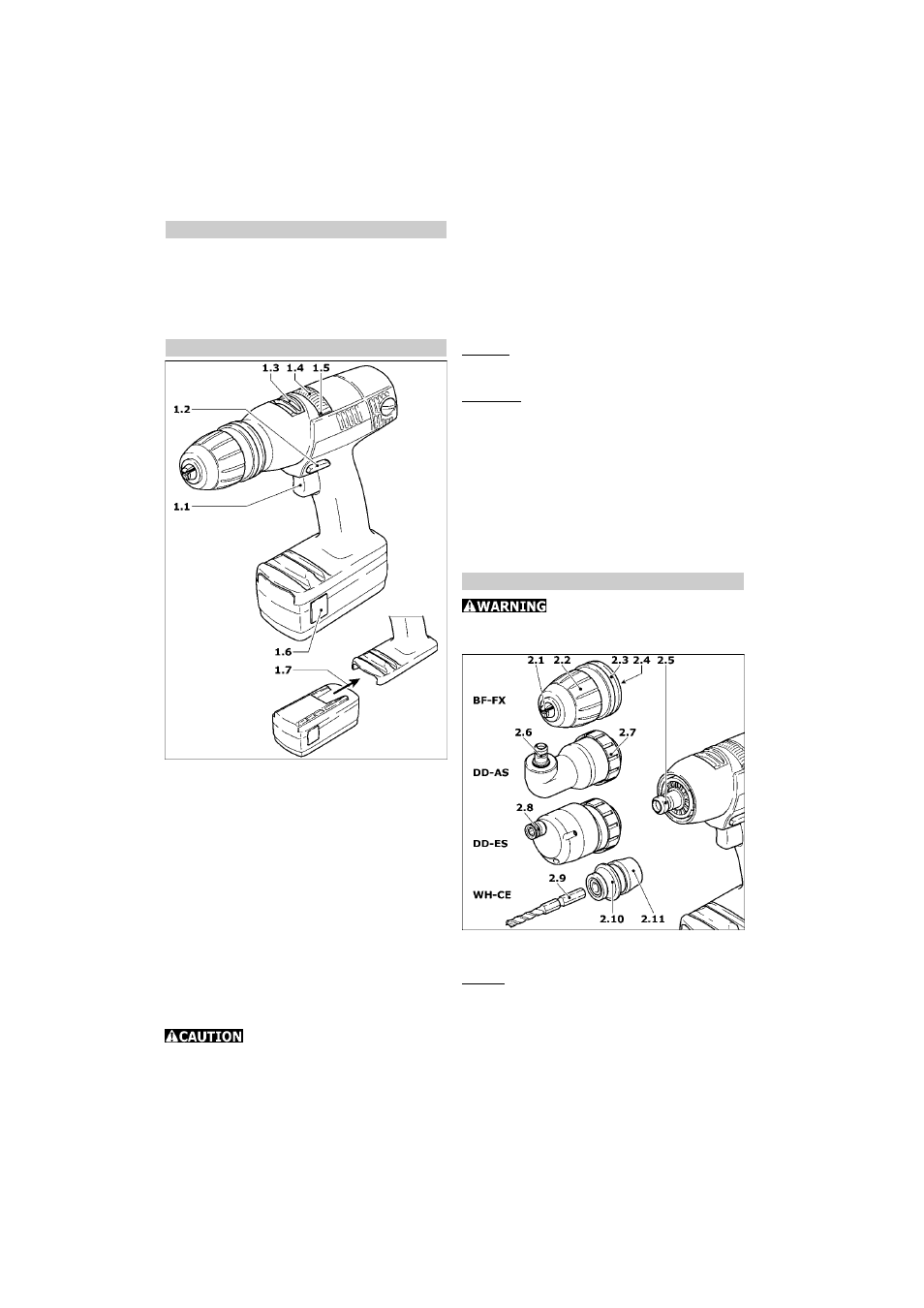

Exchanging the battery pack

- Removing battery pack: Press the two buttons

(1.6) and slide the battery pack forwards to

remove.

- Inserting battery pack: Slide the battery pack

into the holder on the underside of the handle

until it latches into place (1.7).

To change the direction of rotation

The selector button (1.2) determines the direction

of rotation.

• Turn button from right to left = clockwise

rotation.

• Turn button from left to right = anticlockwise

rotation.

• Selector button in central position = circuit

interlock.

Shifting speeds

Change only when completely

stopped!

Using the shift lever (1.3), the speed can be

changed.

• 1. Speed: Lever forward - Figure 1 is visible.

• 2. Speed: Lever backwards - Figure 2 is visible.

Torque adjustment

By turning the adjustment ring (1.4) the required

torque can be adjusted. The arrow (1.5) aligns

with the adjusted state.

Drilling:

Drilling symbol on adjustment ring aligns with

the arrow = maximum torque.

Screwing:

Torque corresponding to setting:

• Position 1 = low torque

• Position 20 = high torque

Operation

Turn on by pressing button (1.1). Depending on

the pressure exerted on the button, the adjust-

ment of running speed can be varied infinitely.

Turn off by releasing the button (1.1). After

releasing the button, the chuck is stopped and

therefore, after-running of the equipment is

prevented.

Tool holding fixture, attachments

Make sure that the machine is

switched of and the battery block has been

removed before changing the tool holding fixture,

attachments and tools.

Chuck BF-FX

The chuck is used to clamp drills and bits.

Fitting:

- Place the chuck on the drill spindle (2.5) and

twist until the hexagon key (2.4) of the chuck

latches into the hexagon socket of the drill

spindle.