Optional gas line installation – FMI (V)3612ST User Manual

Page 12

www.fmiproducts.com

115603-01D

12

refractory cement or commercial furnace

cement, Install the gas appliance or cap

off gas line if desired.

CAUTION: All gas piping

and connections must be tested

for leaks after the installation

is completed. After ensuring

that the gas valve is on, apply

soap and water solution to all

connections and joints. Bubbles

forming show a leak. Correct

all leaks at once. DO NOT USE

AN OPEN FLAME FOR LEAK

TESTING AND DO NOT OPER-

ATE ANY APPLIANCE IF A LEAK

IS DETECTED. LEAK TESTING

SHOULD BE DONE BY A QUALI-

FIED SERVICE PERSON.

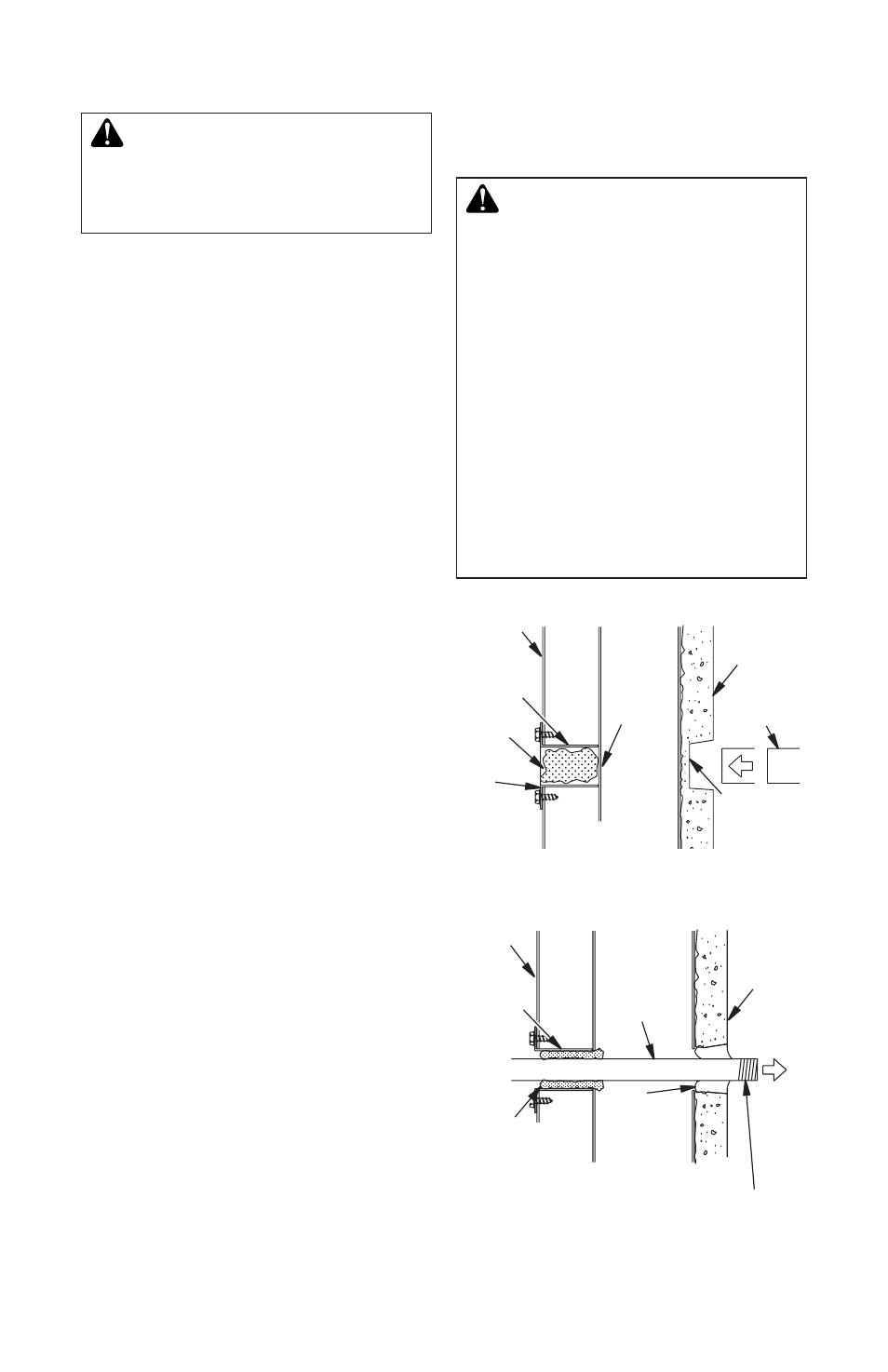

Figure 29 - Gas Line Knockout

Side

Firebrick

Finished

Side

Refractory

Knockout

Plug

Outside of

Fireplace

Gas Line

Conduit

Insulation

Gas

Conduit

Cover

1/2" Dowel

Remove

Knockout

opTional gaS line inSTallaTion

Seal

Opening

with

Refractory

Cement

Outside of

Fireplace

Gas

Line

Conduit

Repack

Insulation

Incoming

1/2" Black

Iron Pipe

Side

Firebrick

Finished

Side

Provide Enough Threaded

End for Fitting Connection

Figure 30 - Gas Line Installation

WARNING: A qualified

service person must connect

fireplace to gas supply. Follow

all local codes.

NOTICE: Before you proceed, make sure your

gas supply is turned off.

A gas line may be installed for the purpose

of installing a vented or vent-free decorative

gas appliance available through your local

distributor. Use only gas piping approved

by local codes. When installing a gas line, a

shutoff valve designed for installation outside

the appliance is recommended.

The gas pipe is intended for connection to a

decorative gas appliance that operates using

natural or propane/LP gas only. This appliance

must have an automatic shutoff device and

must comply with the Standard for Decora-

tive Gas Appliances for Installation in Vented

Fireplace, ANSI Z21.60. ONLY UNVENTED

GAS LOG SETS WHICH HAVE BEEN

FOUND TO COMPLY WITH THE STANDARD

FOR UNVENTED ROOM HEATERS, ANSI

Z21.11.2, ARE TO BE INSTALLED IN THIS

FIREPLACE.

Use only a 1/2" black iron pipe and appropri-

ate fittings.

1. Remove knockout indentation on refrac-

tory or firebrick wall located approximately

2" above the refractory hearth floor. The

knockout indentation must be firmly tapped

with any solid object such as a 1/2" dowel

until it is released. Remove fragmented

portions of refractory (see Figure 29).

2. Remove gas line cover plate located on

rear of fireplace and pull out insulation from

gas line conduit sleeve. Save insulation for

reuse.

3. Run gas line into the fireplace through

the rear at 11

1

/

4

" from floor and through

gas line conduit sleeve (if using a raised

platform, add height). Provide sufficient

gas line into fireplace chamber for fitting

connection (see Figure 30).

Note: Secure incoming gas line to

wood framing to provide rigidity for

threaded end.

4. Repack insulation around gas line and into

sleeve opening. Seal any gaps between

gas line and refractory knockout hole with