Installation, Continued – FMI VFP18MV User Manual

Page 12

12

105071

UNVENTED PROPANE/LP GAS LOG HEATER

FIREPLACE MANUFACTURERS INC.

Pressure Testing gas Supply

Piping system

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1.

Disconnect appliance with its appliance

main gas valve (control valve) and

equipment shutoff valve from gas sup-

ply piping. Pressures in excess of 1/2

psig will damage heater regulator.

2.

Cap off open end of gas pipe where

equipment shutoff valve was con-

nected.

3.

Pressurize supply piping system by ei-

ther using compressed air or opening

propane/LP supply tank valve.

4.

Check all joints of gas supply piping

system. Apply mixture of liquid soap

and water to gas joints. Bubbles form-

ing show a leak.

5.

Correct all leaks at once.

6.

Reconnect heater and equipment

shutoff valve to gas supply. Check re-

connected fittings for leaks.

WARNING: Never use an open

flame to check for a leak. Apply a

mixture of liquid soap and water

to all joints. Bubbles forming

show a leak. Correct all leaks at

once.

WARNING: Test all gas pip-

ing and connections for leaks

after installing or servicing. Cor-

rect all leaks at once.

CAUTION: Make sure exter-

nal regulator has been installed

between propane/LP supply and

heater. See guidelines under

Con-

necting to Gas Supply, page 11.

CHECKING GAS

CONNECTIONS

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

1.

Close equipment shutoff valve (see Fig-

ure 15).

2.

Pressurize supply piping system by ei-

ther using compressed air or opening

propane/LP supply tank valve.

3.

Check all joints from propane/LP sup-

ply tank to equipment shutoff valve (see

Figure 16). Apply mixture of liquid

soap and water to gas joints. Bubbles

forming show a leak.

4.

Correct all leaks at once.

INSTALLATION

Continued

Pressure Testing Heater Gas

Connections

1.

Open equipment shutoff valve (see

Figure 15).

2.

Open propane/LP supply tank valve.

3.

Make sure control knob of heater is in

the OFF position.

4.

Check all joints from equipment shutoff

valve to control valve (see Figure 16). Ap-

ply mixture of liquid soap and water to

gas joints. Bubbles forming show a leak.

5.

Correct all leaks at once.

6.

Light heater (see Operating Heater,

pages 14 and 15). Check all other in-

ternal joints for leaks.

7.

Turn off heater (see To Turn Off Gas to

Appliance, page 15).

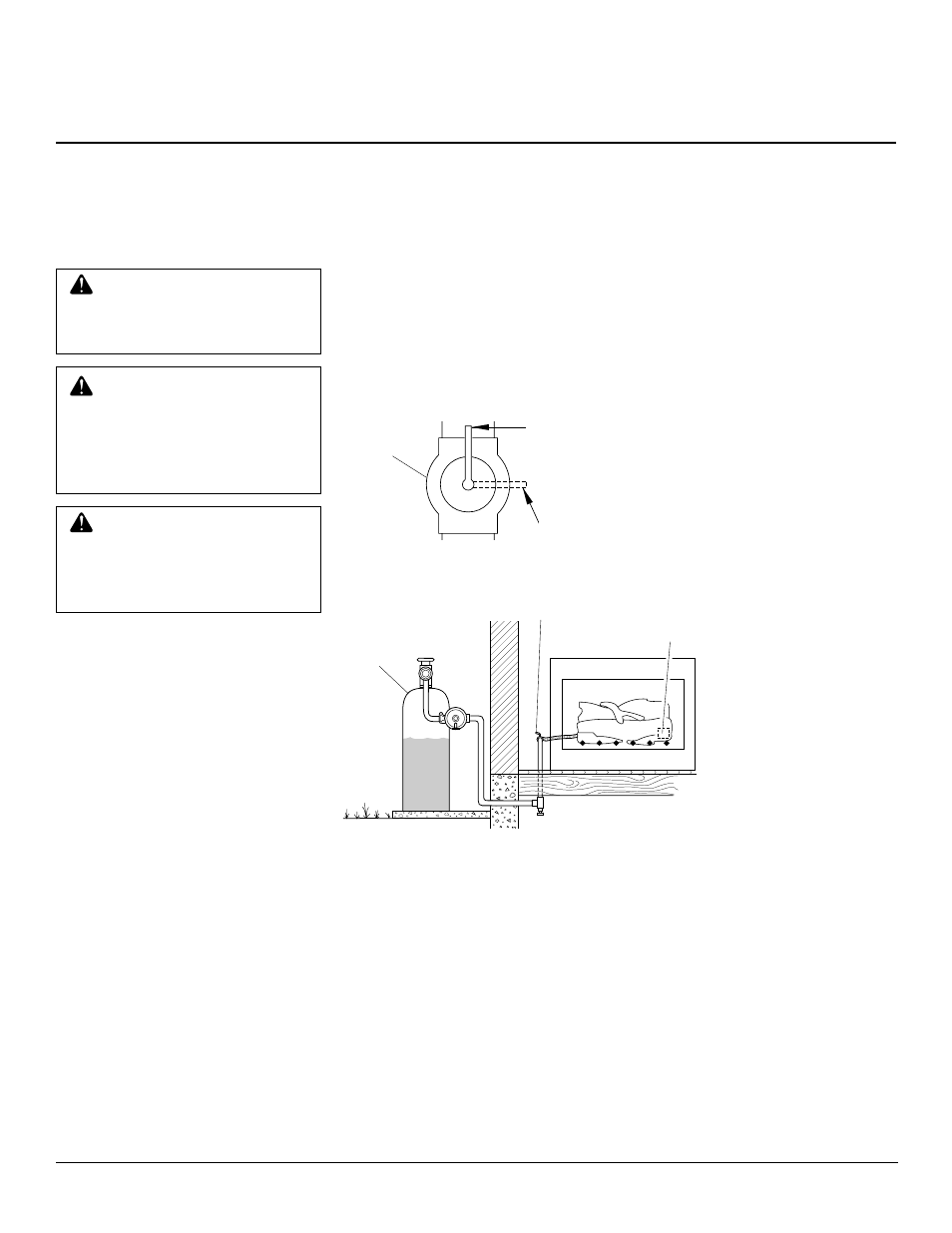

Figure 15 - Equipment Shutoff Valve

Figure 16 - Checking Gas Joints

Control Valve

Location

Propane/

LP Supply

Tank

Equipment

Shutoff Valve

ON

POSITION

OFF

POSITION

Open

Closed

Equipment

Shutoff

Valve