Before you start: sliding window installation, Tools needed – Fedders A6V05S2B User Manual

Page 3

3

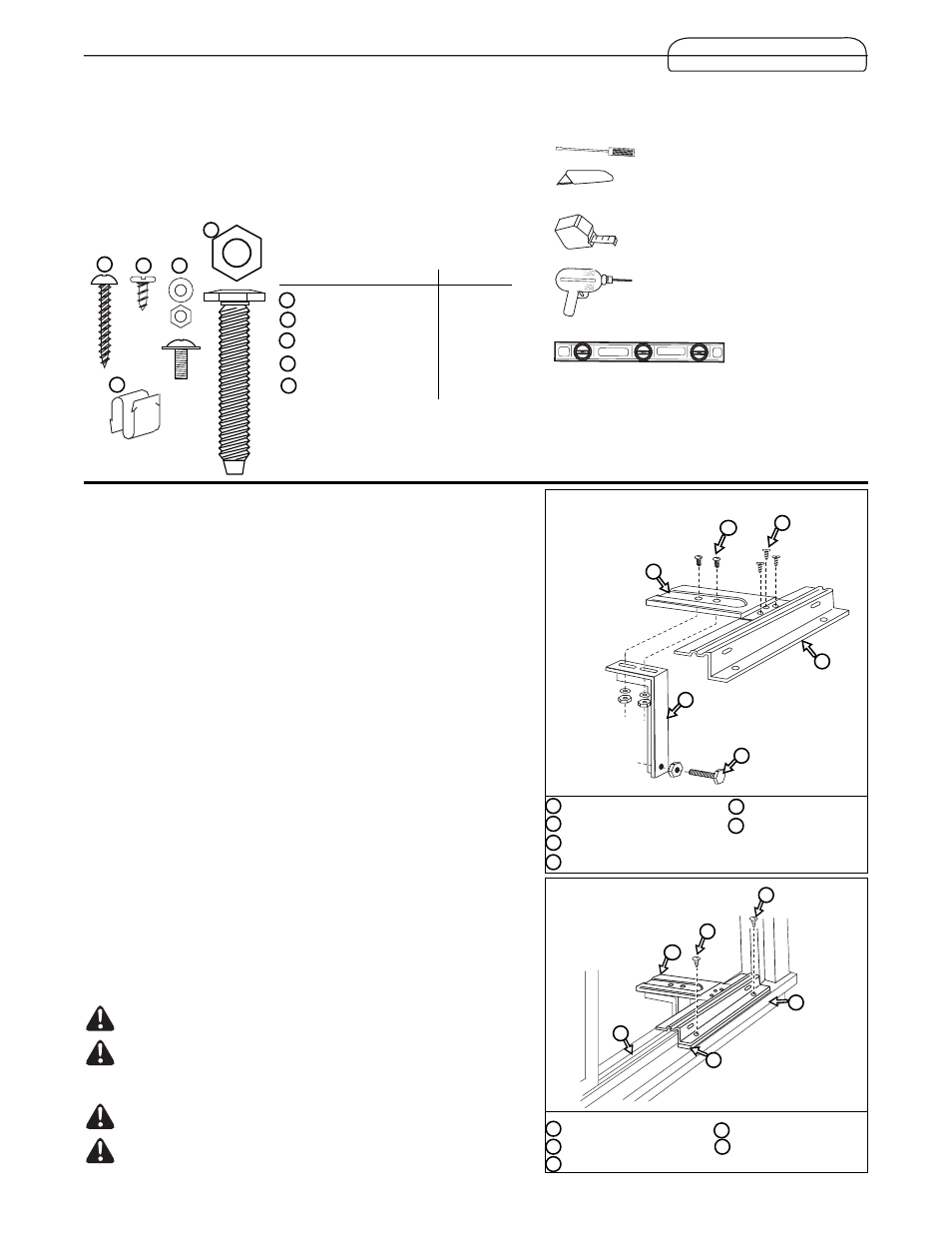

WINDOW INSTALLATON

INSTALLATION

Tools Needed

Screwdrivers

Tape Measure

Carpenter’s Level

Knife

Drill

Window Requirements:

Your new room air conditioner is factory prepared for easy installation

in a horizontal sliding or casement type window with a minimum width

of 15 1/2 inches. Unit will fit a 42 inch high window opening as

received from factory.

Use caution when working around exposed sharp edges

of the cabinet and sharp coils to avoid injury or torn

clothing.

Make sure unit is unplugged before removing the

decorative front.

It is recommended that you have help to install your unit

and that you use proper lifting technique to avoid

personal injury.

A

B

C

D

E

Support Platform

7/16” mach. screws

3/8” Self tapping screws

Sill plate

Support Angle

Leveling Bolt

A

B

C

D

E

F

F

A

A

B

C

D

E

1” long screws

Support Platform

Lower window track

Window Sill

Shim Strip

A

B

C

D

E

Before you start:

Sliding Window Installation

Make sure unit is unplugged before removing chassis

from cabinet.

1.

Choose the installation site. It is imperative that window frame

assembly and side of structure are adequate to support weight of

unit. Reinforce if necessary.

2. Slide open one window sash to install support platform.

3. Attach support platform to sill plate with three (3) 3/8” long self-

tapping screws (Fig. 3).

4. Loosely attach support angle to bottom of support platform using

two (2) 7/16” long machine screws, flat washers, and nuts.

5. Place support platform against lower window track and firmly

against vertical edge of window frame (Fig. 4).

6. Attach support platform to window sill using two (2) 1” long

self-tapping screws (Fig. 4).

If required, overcome interference of support platform with

window track or storm windows by securely attaching a shim

strip to the window sill. Strip should be as long as width of

support platform and flush with back edge of sill. Thickness of

strip should be controlled by amount of interference.

7. Pull support angle against outside of structure. Tighten two (2)

7/16” long machine screws on top of support platform (Fig. 3).

8. Adjust leveling bolt to position support angle in a level plane.

This will allow for proper angle. Tighten leveling bolt locknut

(Fig. 3).

Important: Unit must be level or tilted back slightly to facilitate proper

condensate disposal.

Fig. 4

Fig. 3

1” long wood screws

2

3/8” Self tapping screws

7

7/16” mach. screws/nuts

2

Leveling Bolt/ Nut

1

Speed Clips

2

A

B

C

D

E

A

B

C

D

E

Installation Parts Kit

Fastener Identification

Description

Quantity

SUPPORT PLATFORM ASSEMBLY

The installation is intended to be permanent, and when installed in

apartment or rental properties, permission to make modifications

should be obtained from owners or landlords of buildings prior to

installation of unit.