Field Controls SWGII-6 User Manual

Page 3

page 3

INSTALLATION

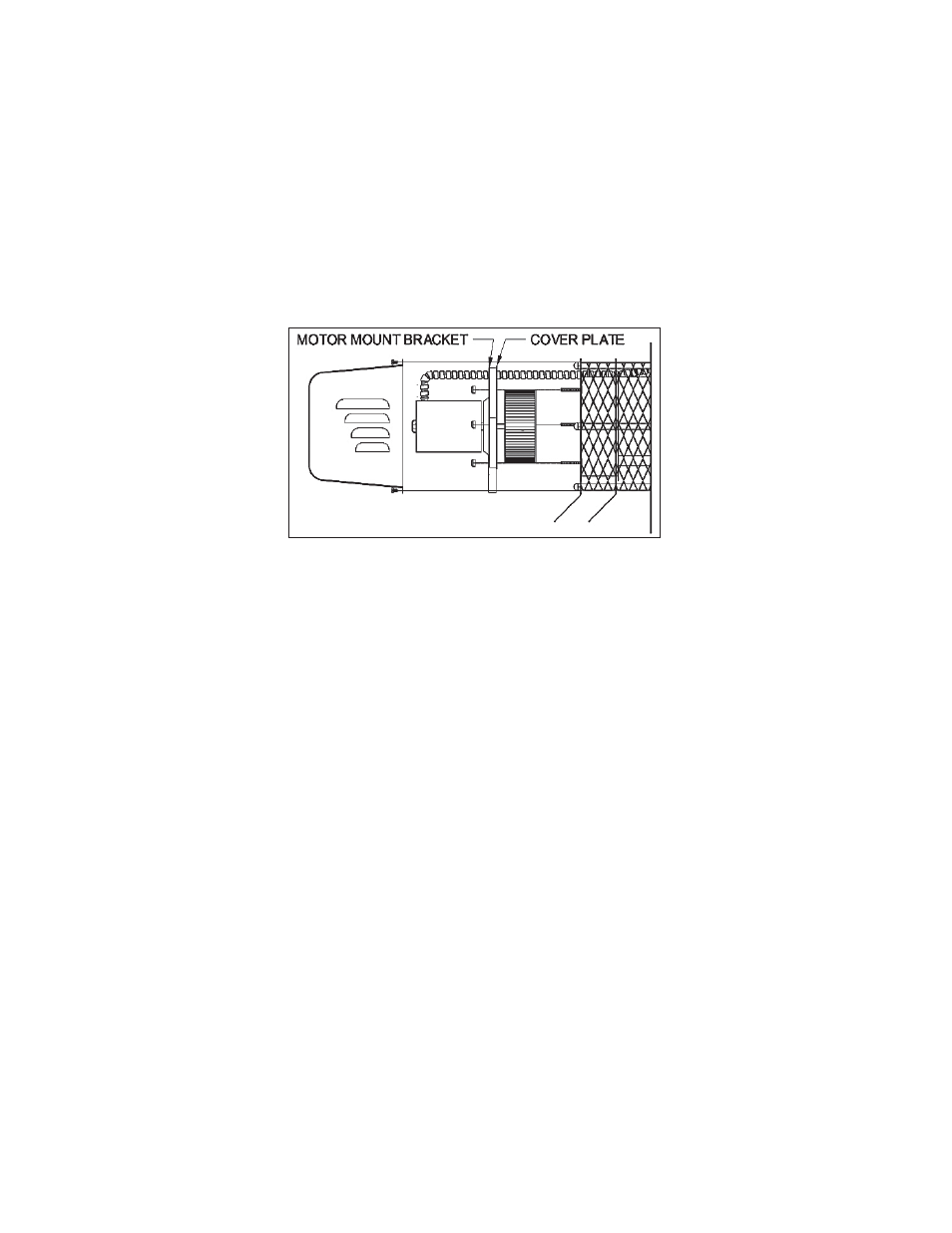

1. Align the holes in the circular cover plate with the holes in the motor mount bracket on the motor

assembly. (See Figure 3)

2. Slide the motor assembly onto the protruding threaded studs on the power venter body with the exhaust

chute pointing downward, and replace the nuts securely to the threaded studs. (See Figure 3)

3. Use the top knockout on the electrical box and reattach the fl exible conduit and wires to the motor using

the conduit connector and wire nuts. Secure the cover on the electrical box.

4. Seal around the edge of the motor mount bracket with the provided high temperature silicone sealant.

Install the motor cover with the side louvers pointing downward. (See Figure 1)

Figure 3

MAINTENANCE

1. Motor: Inspect the motor once a year - motor should rotate freely. To prolong the life of the motor, it must be

lubricated with six drops of SWG Superlube, Part # 46226200, annually. NOTE: Some models may have sealed-

bearing motors, which do not require lubrication.

2. Wheel: Inspect the power venter wheel annually to clear any soot, ash or coating which inhibits either rotation

or air fl ow. Remove all foreign materials before operating.

3. Vent System: Inspect all vent connections annually for looseness, for evidence of corrosion and for fl ue gas

leakage. Replace, seal or tighten pipe connections if necessary. Check the power venter choke plate to ensure

it is secured in place. Check the barometric draft control, if installed, to ensure the gate

swings freely.

4. System Safety Devices: With the heating system operating, disconnect the pressure sensing tube from

the pressure switch on the CK Kit. This will stop the burner operation. Re-connecting the tube will relight

the burner. For 30 millivolt operating systems, disconnect one lead of the spill switch circuit from the

thermocouple junction block. This will shut off the pilot and the burner. Re-connection will allow relighting

the pilot.