Service – Follett C45184 User Manual

Page 9

Annual cleaning

Removal of dust and other particulates from air intake areas and the

condenser is important for proper operation. Some environments with

large amounts of dust may require more frequent cleaning.

1. Disconnect power to unit by turning switch on the lower

front panel to the OFF position, switching circuit breaker

to OFF position, and removing power cord from receptacle.

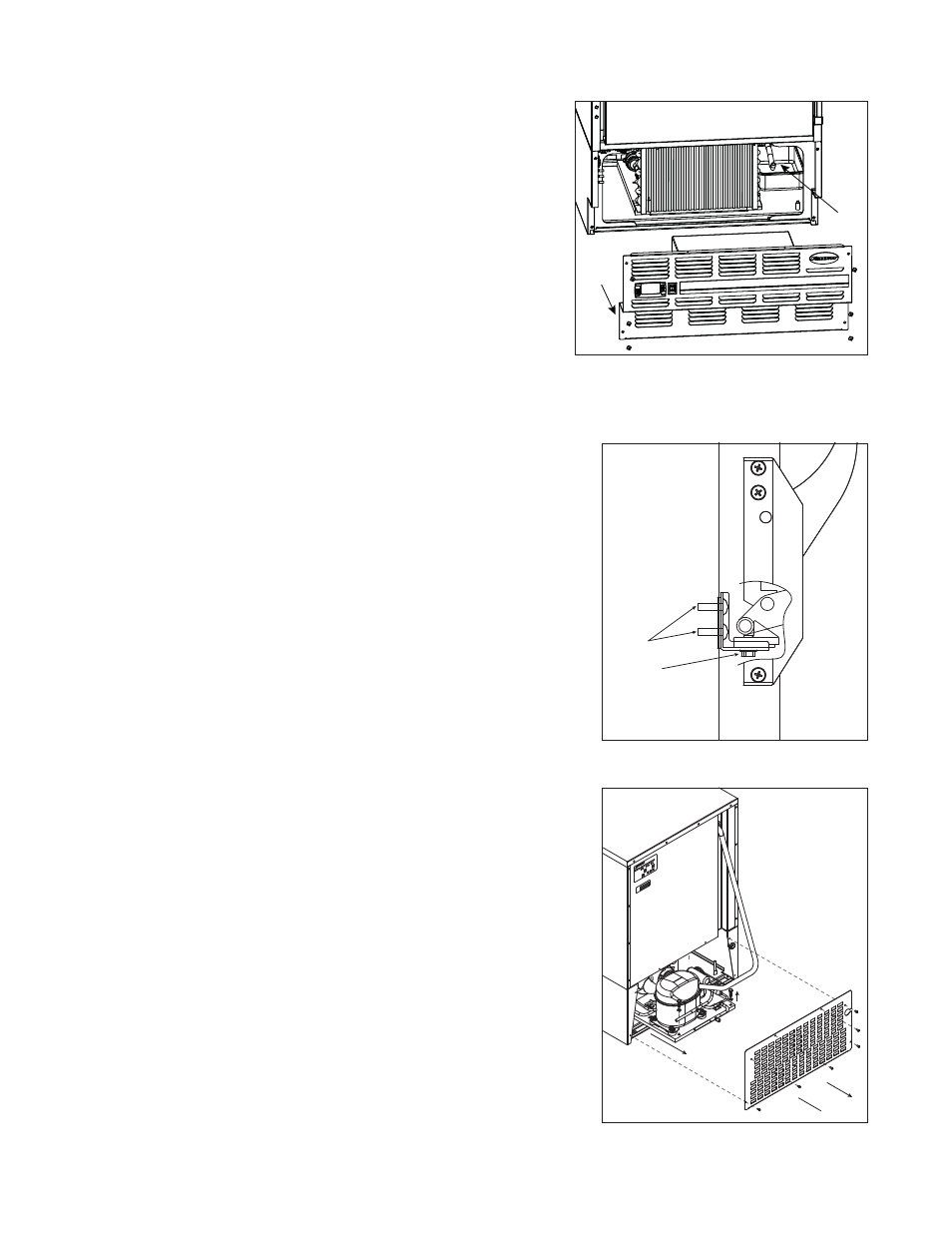

2. Remove lower front panel (Fig. 6.1).

Note: Front louvered panel may be completely removed for

easier cleaning by disconnecting the controller wiring plugs from

the freezer.

3. Remove drain pan (Fig. 6.2).

4. Clean drain pan with a non-abrasive, non-chlorinated

all-purpose detergent.

5. Reinstall drain pan.

6. Use a vacuum cleaner with brush attachment to clean

condenser through lower front panel and compressor

motor and related parts through lower rear panel.

7. Reinstall lower front panel.

Service

Latch adjustment

To adjust for proper latch engagement

1. Loosen striker plate mounting screws (Fig. 7.1).

2. Move striker plate up or down as required and tighten screws.

3. Test operation of latch.

To adjust for proper gasket seal

1. Loosen striker depth adjustment screw (Fig. 7.2).

2. Adjust stop in or out and tighten screws.

3. Test operation of latch.

Door gasket replacement

1. Remove existing gasket from mounting track.

2. Verify mounting track is free of any remaining gasket material.

3. Align new gasket with mounting track and press fi rmly in place.

4. Open and close door, checking for proper gasket seal without

pinching against freezer.

5. Adjust latch and or striker as necessary for proper door closure.

Slide-out compressor tray

Follett’s slide-out compressor tray allows technicians to partially slide

the condensing unit from the freezer back without cutting refrigerant

lines.

1. Remove rear panel (Fig. 8.1).

2. Remove two bolts securing condensing unit to freezer base

(Fig. 8.2).

3. Gently slide condensing unit out (Fig. 8.3).

Note: Do not put undue strain on the refrigerant lines.

9

1

2

Fig. 7

20

82

64

Pro

duc

t

Mod

ule

No.

Ser

vice

No

.

Easton P

ennsylv

ania

MO

TO

R COMPRESSOR THER

MALL

Y PR

OTECTED

DESIGN PRESSURE HIG

H SIDE

MIN

. B

RAN

CH

C

IR

CUIT AMP

AC

ITY

MAX.

BRANC

H C

IR

CUIT FUSE SIZE

SINGLE

PHASE

LO

W SIDE

L

THE USA

MA

DE I

N

OZ

PS

IG

R

C

NS

F

UL

PA

RT

N

O

HZ

CHARGE

AM

PS

R

AM

PS

U

VO

LTS

CORPORA

TION

SERIAL NO

MODEL

FULL LO

AD AMPS

REFRIGERANT

1

2

3

Fig. 8

Fig. 6

1

2