Low engine power, Engine not running smoothly – Harbor Freight Tools 96500 User Manual

Page 10

Page 10

SKU 96500

for technical questions, please call 1-800-444-3353.

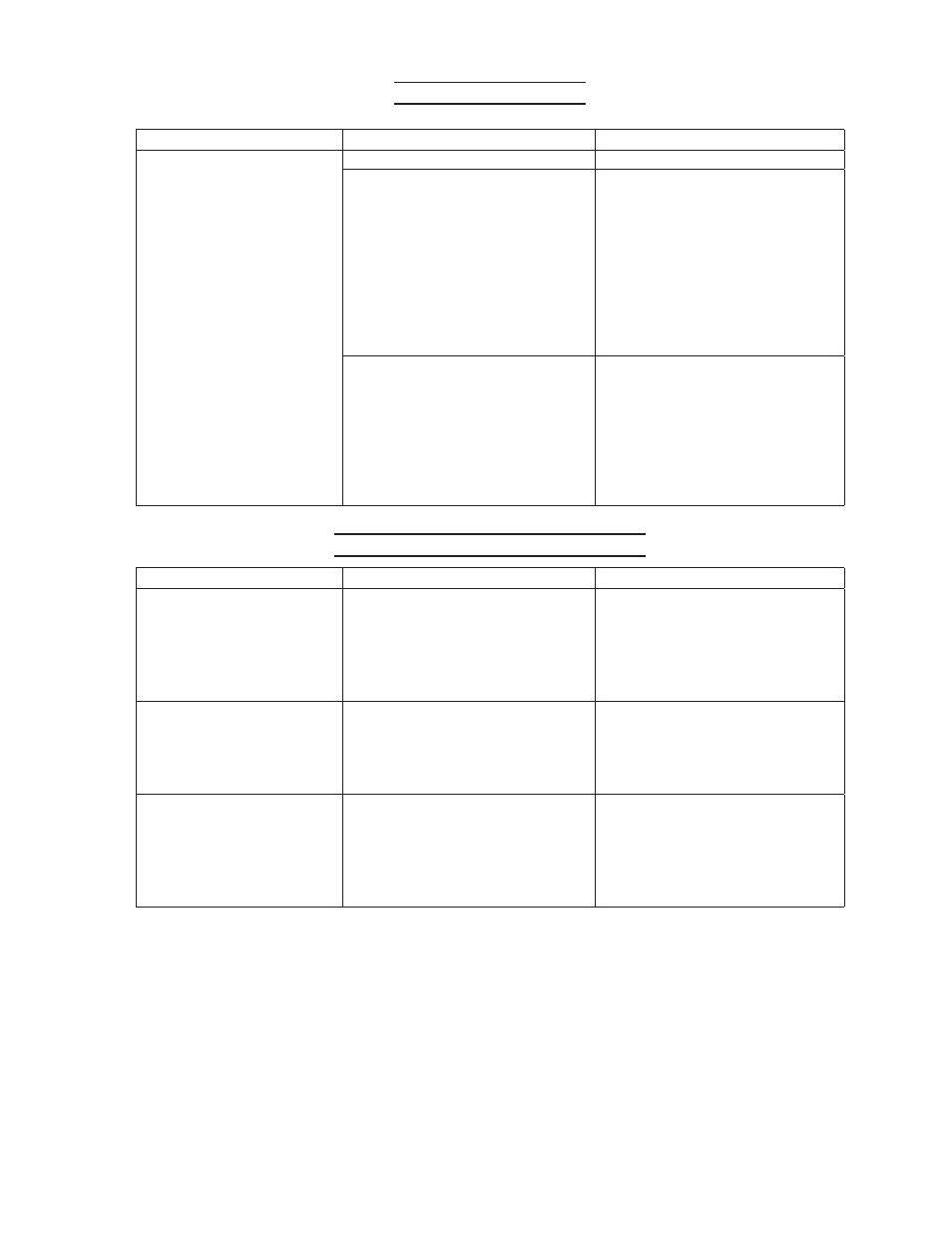

low engine power

symptom

probable cause

possible remedy

When pressing Throttle

for higher speed, engine

responds slowly; speed is

decreased; or engine stops.

Incorrect Ignition timing.

Re-adjust ignition advance angle.

Fuel supply problem:

1. Fuel line is clogged or has air

2. Main jet not adjusted properly

3. Carburetor needle valve hole

and main jet clogged

4. Gas valve clogged

5. Carbon buildup in combustion

chamber.

6. Air filter is clogged.

7. Intake pipe leaking.

1. Clean line. Bleed line of air.

2. Readjust jet.

3. Clean needle valve hole and

main jet

4. Clean or replace gas valve.

5. Clean combustion chamber.

6. Clean filter elements.

7. Repair or replace.

Low compression:

1. Piston, piston ring, or cylinder

worn.

2. Air leakage from surface where

cylinder block contacts cylinder

head.

3. Valve clearance incorrect.

4. Valve tightness poor.

1. Replace damaged part.

2. Replace cylinder gaskets.

3. Adjust valve.

4. Repair or replace valve.

engine not running smoothly

symptom

probable cause

possible remedy

Engine pinging.

1. Piston, ring, or cylinder worn.

2. Piston pin and pin hole are

worn excessively.

3. Tie rod small head is worn.

4. Main crankshaft roller bearing

worn.

1. Replace worn part.

2. Replace piston and/or pin.

3. Replace tie rod.

4. Replace roller bearing.

Abnormal combustion.

1. Engine too hot.

2. Carbon fouling in combustion

chamber.

3. Wrong gasoline type.

1. See Troubleshooting page 11,

Engine Excessively Hot

2. Clean chamber.

3. Drain gas from system and

replace with correct type.

Spark plug not firing

correctly

1. Water in carburetor float

chamber.

2. Spark plug electrode gap

wrong.

3. Incorrect ignition timing.

4. Ignition coil malfunction.

1. Clean Carburetor.

2. Adjust spark plug gap.

3. Re-adjust.

4. Repair or replace coil.