Trouble shooting – I.C.T.C. Holdings Corporation 1240 User Manual

Page 19

HERO Operator’s Manual – Page 18 of 23

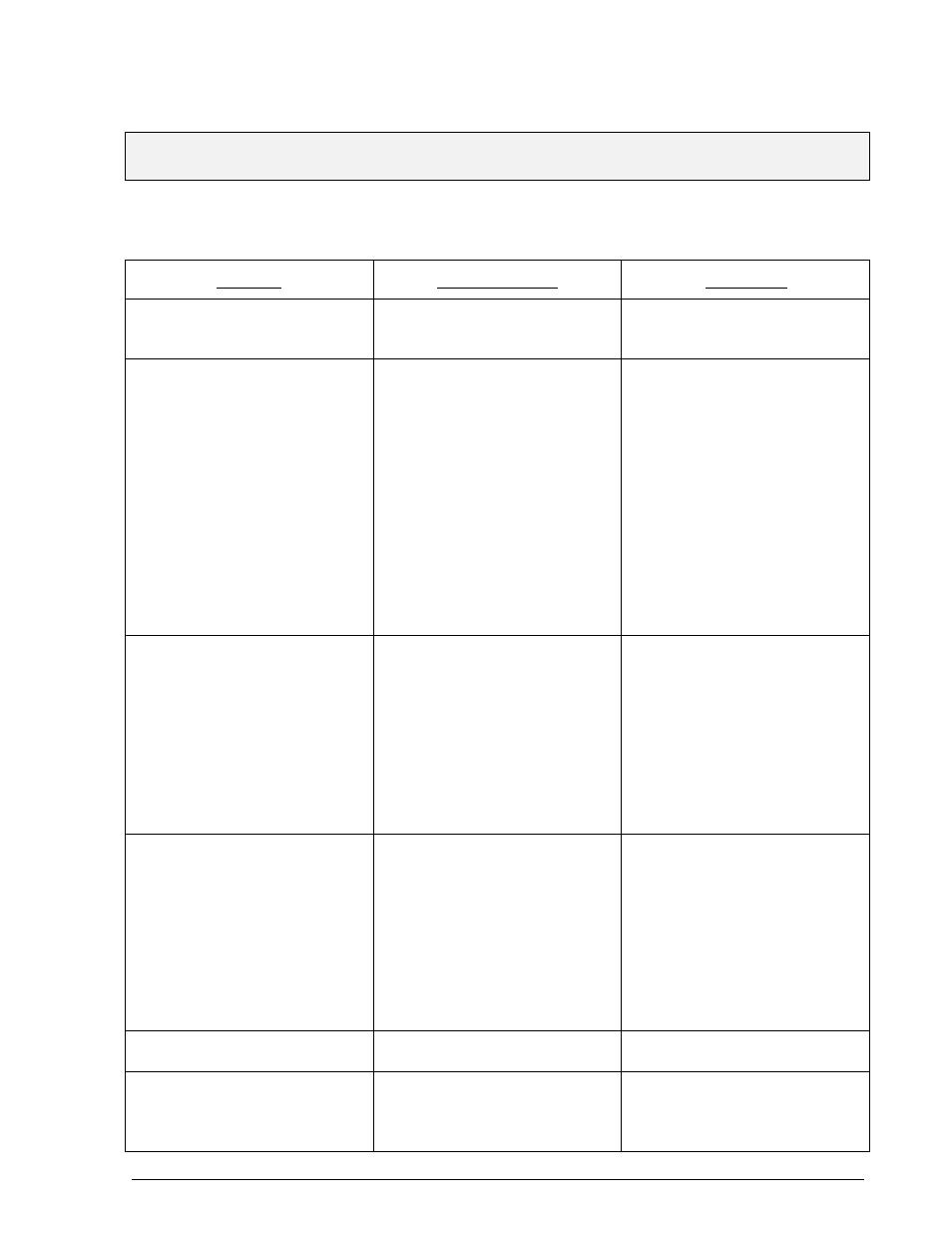

TROUBLE SHOOTING

5.1

BASIC TROUBLESHOOTING CHART

Problem

Probable Cause

Solution(s)

Turbine not working at all

A. No power to the turbine

B. Re-settable breaker has been

activated

A. Check power outlet/socket

B. Re-set breaker on face of

turbine by pressing it once

Low Air Flow

A. Filters are blocked

B. Turbine air vents are

obstructed

C. Kink in hose

D. Broken or damaged hose

E. Motor mounts broken

F. Motor outlet leaking air:

gasket is worn

A. Clean or replace filters as

necessary

B. Allow air to flow freely

around turbine

C. Remove kink and straighten

hose

D. Inspect hose: repair or

replace if necessary

E. Open turbine cabinet and

inspect: replace if possible or

contact HERO

F. Open turbine cabinet and

inspect: replace if possible or

contact HERO

Turbine/Hose/Gun Overheating

A. Ambient air is hot

B. Turbine foam filters are

blocked

C. Turbine air vents are

obstructed

D. Due to speed of turbine

motor, system normally gets

warm

A. Use in cooler environment if

possible

B. Clean or replace filters as

necessary

C. Allow air to flow freely

around turbine

D. Additional lengths of hose

will reduce heat build-up in

gun

??

Wear gloves

Uneven Spray Pattern

A. Air Cap holes plugged

B. Dry paint on Fluid Tip

C. Incorrect Needle/Fluid Tip/

Air Cap combination

D. “Figure 8”: Air Cap too close

to Fluid Tip

A. Clean or replace Air Cap as

necessary

B. Clean Fluid Tip and continue

spraying

C. See Sec. 3.3 for proper

selection, and Sec. 3.8 for

proper testing

D. Turn Sleeve Nut counter-

clockwise to move Air Cap

away from Fluid Tip

Fluid Leaking From Paint Cup

and/or

Bubbling In Paint Cup

A. Cup Top Gasket not sealing

properly

A. Tighten cup or see Sec. 4.5,

Replacing Cup Top Gasket

Fluid Leaking Between Gland

Nut And Needle Directly In

Front Of Trigger

A. Gland Nut too loose

B. Gland Seal worn out

A. Tighten Gland Nut

B. See Sec. 4.6, Replacing

Gland Seal