Specifications, Unpacking, Operating instructions – Harbor Freight Tools 9576 User Manual

Page 5

Page 5

For technical questions, please call 1-800-444-3353.

SKU 9576,

94639

reV 08e, 10a

sPecIFIcaTIOns

Model

9576

94639

Motor

12 VDC / 50 W

/ 4,500 RPM

12 VDC / 110 W

/ 4,500 RPM

Application

Utility Water

Pumping,

including

marine

applications

Utility Water

Pumping

Power Wires

18 AwG x 19” Long (Qty. 2)

Discharge

Height*

23 ft.

Flow Rate*

200 GPh

300 GPh

Self Priming

Yes

Construction

Stainless Steel Pump Housing

Steel Motor Housing

Dual Threaded

Inlet

3/8”-18 NPT Female I.D.

3/4” Male O.D.

Dimensions

5-3/4” L x 2-1/2” Dia. x 4” h

*note: For optimal performance, the

suction hose (not included) I.D.

must be at least the same size as the

suction flange and free of air leaks.

All joints and connections of the suction

hose should be securely tightened to

prevent air from entering

the suction

side. Use a good grade suction hose

that will not collapse.

In addition, the height from the inlet

to the pump and then the height from

the outlet to the discharge will

greatly

impact pump performance.

UnPacKIng

When unpacking, make sure the item

is intact and undamaged. If any parts are

missing or broken, please call Harbor Freight

Tools at 1-800-444-3353 as soon as possible.

OPeraTIng InsTrUcTIOns

nOTe: For additional reference to the parts

mentioned in the following pages, refer

to the

assembly Diagram at the end of

this manual.

nOTe: Mount the pump permanently to

a flat surface only. Do not mount the

Pump on a rounded surface. (Hardware

for permanently mounting the Utility

Pump is not included.)

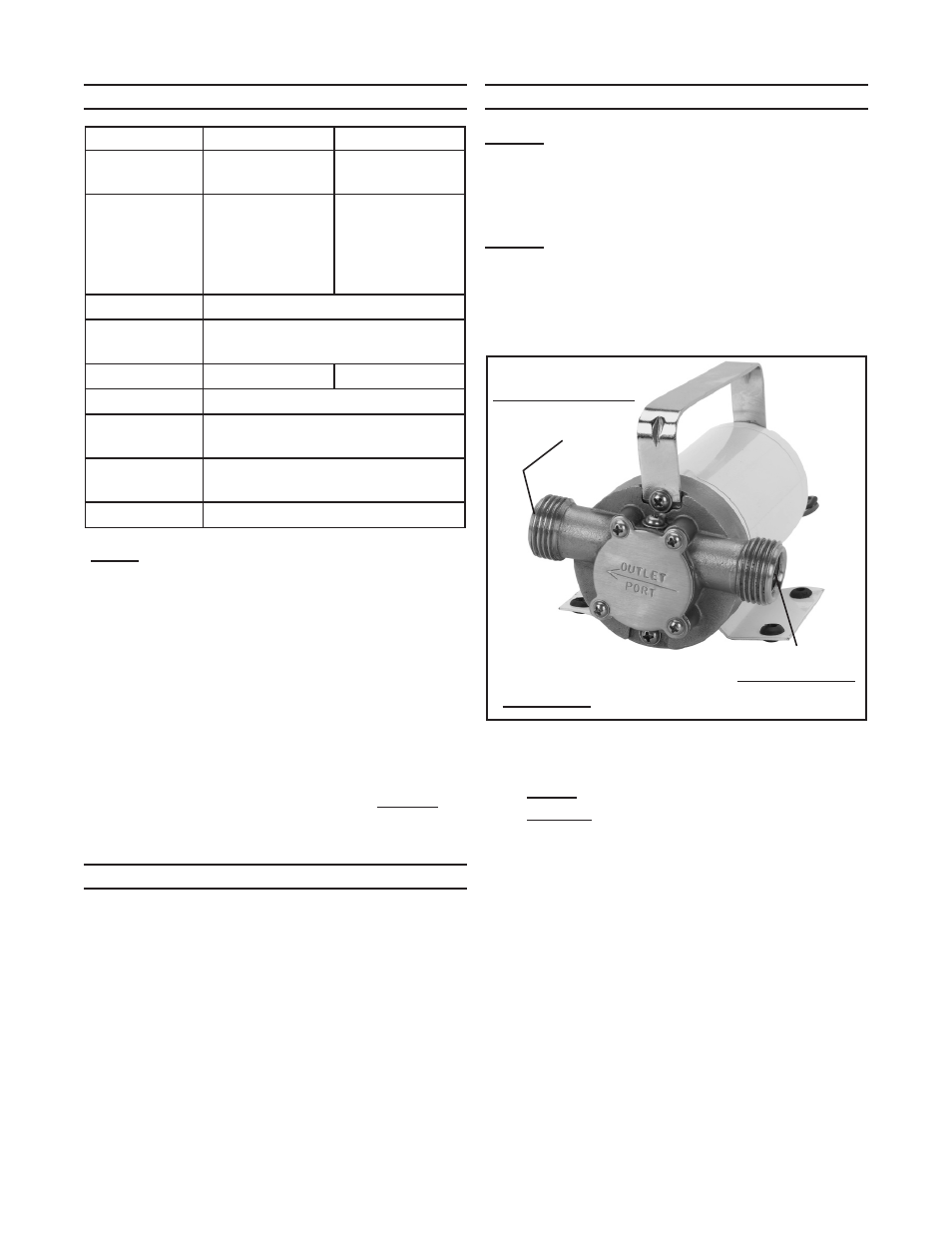

cOnnecT

sUcTIOn hOse

(nOT IncLUDeD)

here.

cOnnecT

DIscharge hOse

(nOT IncLUDeD)

here.

FIgUre a

1. The Inlet and Outlet Ports on the Utility

Pump are both dual threaded with an

Inside Diameter of

3/8” NPT and an

Outside Diameter of

3/4”. This allows

for more versatility in selecting a suction

hose and discharge hose (not included)

with the proper threaded male or female

connector.

(see Figure a.)

If you are connecting a suction hose

2.

having a threaded male connector,

wrap about 4” of pipe seal tape (not

included) around the threads of the

male connector. Then, firmly screw the

male connector into the threaded female

connector of the Utility Pump. Repeat