Checkout, W7753a checkout, Step 1. check installation and wiring – Honeywell EXCEL 10 W7753A User Manual

Page 8: With a minimum of 18 awg (1.0 mm, W7753a unit ventilator controller

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

95-7520—02

8

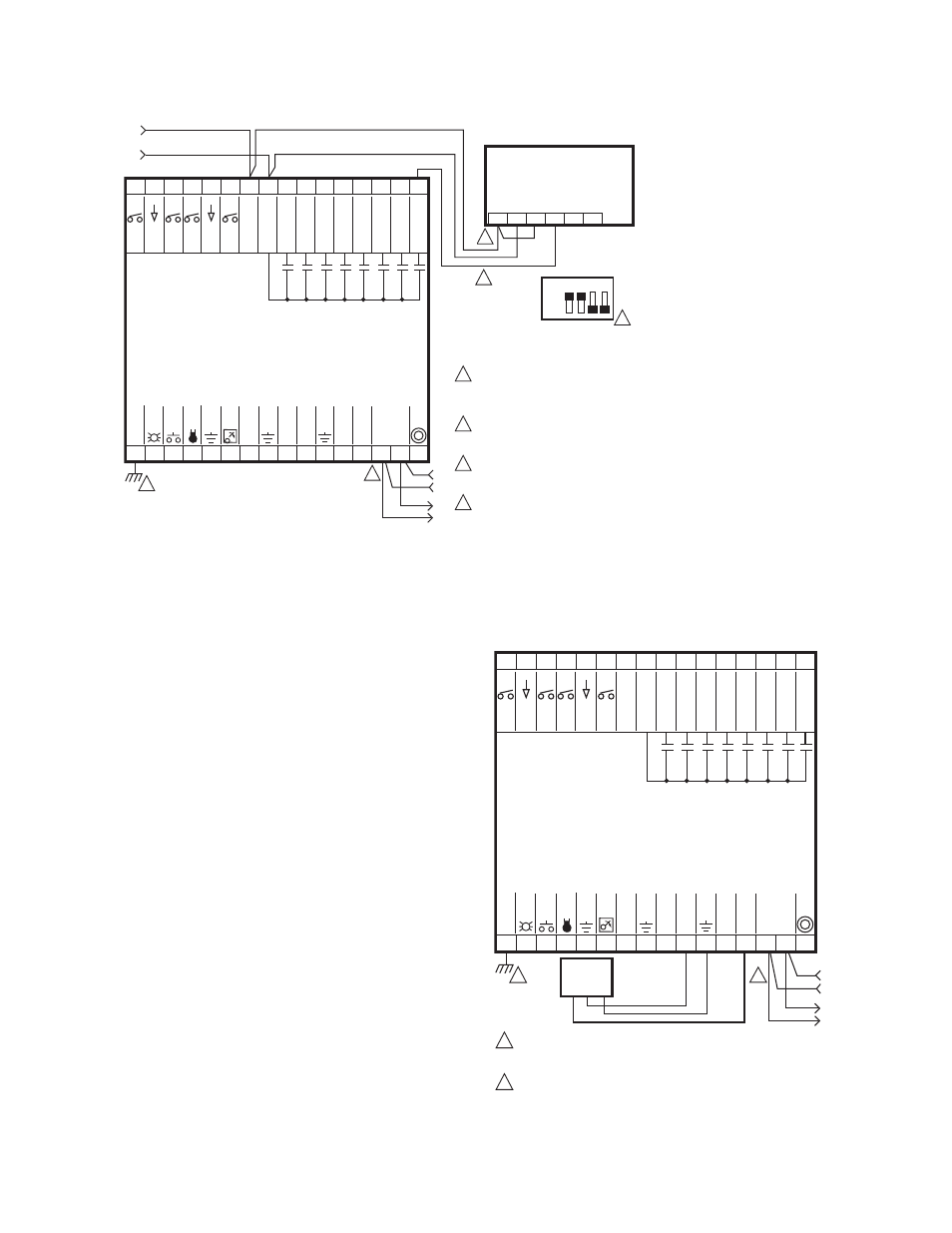

Fig. 13. Typical PWM Valve Actuator to W7753A. (For note 2, refer to Fig. 8.)

NOTE: Make sure to set the Configuration DIP Switch as shown in Fig. 13. Switches 1 through 3 set the timing of the ML7984B

valve actuator to match the W7753A outputs (0.1 sec. Min. with a max. time of 25.6 sec.).

Switch 4 determines the action of the actuator (Off = Direct Acting, On = Reverse Acting).

CHECKOUT

W7753A Checkout

Step 1. Check Installation and Wiring

Inspect all wiring connections at the W7753A terminals and

verify compliance with installation job drawings. If any wiring

changes are required, first be sure to remove power from the

controller before starting work. Pay particular attention to:

— 24 Vac power connections. Verify that multiple controllers

powered by the same transformer are wired with the

transformer secondary connected to the same input

terminal numbers on each W7753A. See Fig. 5. (Controller

configurations are not necessarily limited to three

controllers, but the total power draw including accessories

cannot exceed 100 VA when powered by the same

transformer (U.S. only). See System Engineering,

form 74-2964, for power wiring recommendations.

— Controller wiring. Be sure that each controller is wired

(terminal 1) on the W7753A to a verified earth ground

using a wire run as short as possible with the heaviest

gauge wire available, up to 14 AWG (2.0 mm

2

) with a

minimum of 18 AWG (1.0 mm

2

) for each controller in the

group. See Fig. 4.

— Verify Triac wiring to external controllers uses the proper

load power/24 Vac hot terminal (terminal 25 on the

W7753A).

NOTE: All wiring must comply with applicable electrical

codes and ordinances or as specified on installation

wiring diagrams.

Fig. 14. Typical 2 to 10 Volt DC humidity sensor to

W7753A. (For note 2, refer to Fig. 8.)

1

2

3

4

5

6

7

8

E-BUS

24 V

A

C

1

2

E-BUS

E GND

GND

SNSR

SETPT

LED

BYP

ASS

GND

GND

9

10 11 12

14

J3

15

31 30 29 28 27 26 25 24 23 22 21 20

24 V

AC COM

E-BUS JACK

22 VDC OUT

19 18 17 16

AI-1 OHM

AI-2 OHM

AI-4 V/mA

OUT

7

OUT

6

OUT

5

OUT

4

OUT

8

OUT

1

OUT

3

OUT

2

AI-3 V/mA

13

DI-2

DI-4

DI-1

DI-3

M12694

GND

GND

TRIAC EQUIVALENT CIRCUIT

24 VAC

+

-

2

1

2

3

3

4

EARTH GROUND WIRE LENGTH SHOULD BE HELD

TO A MINIMUM. USE THE HEAVIEST GAUGE WIRE

AVAILABLE, UP TO 14 AWG (2.O MM

2

) WITH A MINIMUM

OF 18 AWG (1.O MM

2

), FOR EARTH GROUND WIRE.

TO ASSURE PROPER ELECTRICAL CONTACT, WIRES

MUST BE TWISTED TOGETHER BEFORE INSERTION

INTO THE TERMINAL BLOCK.

MAKE SURE ALL TRANSFORMER/POWER WIRING

IS AS SHOWN:REVERSING TERMINATIONS WILL

RESULT IN EQUIPMENT MALFUNCTION.

TURN POWER OFF BEFORE SETTING THE DIP SWITCHES.

1 2 3 4

4

24 (H)

24 (N)

PWM (H 24 V

A

C)

PWM OUTPUT

FROM CNTRL

PWM VALVE ACTUATOR

PWM VALVE

ACTUATOR

ML7984B

T6 T5

C

B

W

R

ON

OFF

CONFIGURATION DIP SWITCHES

(LOCATED ADJACENT TO THE

INPUT TERMINAL BLOCK)

W7753A

UNIT

VENTILATOR

CONTROLLER

1

2

3

4

5

6

7

8

E-BUS

24 V

A

C

W7753A

UNIT

VENTILATOR

CONTROLLER

1

2

E-BUS

E GND

GND

GND

OUT

+V

SNSR

SETPT

LED

BYP

ASS

GND

GND

9

10 11 12

14

J3

15

31 30 29 28 27 26 25 24 23 22 21 20

24 V

AC COM

E-BUS JACK

22 VDC OUT

19 18 17 16

AI-1 OHM

AI-2 OHM

AI-4 V/mA

OUT

7

OUT

6

OUT

5

OUT

4

OUT

8

OUT

1

OUT

3

OUT

2

AI-3 V/mA

13

DI-2

DI-4

DI-1

DI-3

M12696

GND

GND

TRIAC EQUIVALENT CIRCUIT

C7600B

1

2

EARTH GROUND WIRE LENGTH SHOULD BE HELD TO A MINIMUM. USE

THE HEAVIEST GAUGE WIRE AVAILABLE, UP TO 14 AWG (2.O MM

2

) WITH

A MINIMUM OF 18 AWG (1.O MM

2

), FOR EARTH GROUND WIRE.

TO ASSURE PROPER ELECTRICAL CONTACT, WIRESMUST BE TWISTED

TOGETHER BEFORE INSERTIONINTO THE TERMINAL BLOCK.

HUMIDITY

SENSOR

(2 TO 10 VOLT)