Delta Electronics Programmablelogic Controller DVP-Slim User Manual

Ext ensi on port, Pow er l. v ext ensi on port, D v p

Warning

Please read this instruction sheet carefully before use.

DVP-SLIM is an OPEN-TYPE device and therefore should be installed in an enclosure free of airborne dust, humidity,

electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the device (e.g. key

or specific tools are required to open the enclosure) in case danger and damage on the device may occur.

DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check all

the wiring again before switching on the power. DO NOT touch any terminal when the power is switched on.

Introduction

Thank you for choosing Delta DVP-Slim series programmable logic controller. DVP-Slim digital I/O extension unit offers 6 ~

16 points, and the maximum digital I/O extension points (including the MPU) can reach 256 points. In addition, maximum 8

additional special modules (AD/DA/PT/TC/XA/PU) can be extended to DVP-Slim series extension unit.

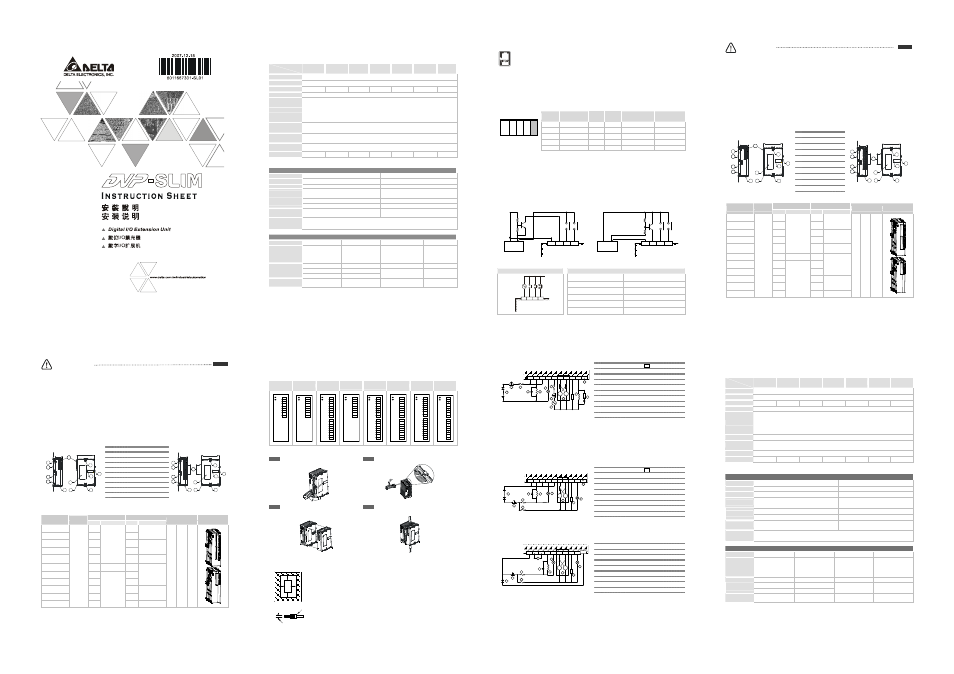

Product Profile & Outline

1 POWER, L.V (low voltage) indicator

2 Model name

3 Extension unit fixing clip

4 I/O terminals

5 DIN rail clip

6 Extension unit positioning hole

7 Nameplate

8 Extension unit fixing clip

9 DIN rail (35mm)

EXT ENSI ON

PORT

6 0

8

8

9

10

4

4

7

5

6

2 5 . 2 0

3

.0

0

9

0

.0

0

3

.0

0

3

1

2

3

POWER

D

V

P

-

L.V

Connection port for extension unit

3

.0

0

9

0

.0

0

6

5

8

6 0

3

.0

0

2 5 .2 0

2

7

3

3

1

4

4

POW

ER

L. V

EXT ENSI ON

PORT

9

10

8

●

●

●

●

●

D

V

P

-

Model Information

Input

Output

Model name

Power

supply

Points

Type

Points

Type

Dimension (mm)

Outline

DVP08SP11R

4

4

DVP16SP11R

8

8

Relay

DVP08SP11T

4

4

DVP16SP11T

8

8

Transistor

(Sink)

DVP16SP11TS

8

DC Type

Sink/Source

8

Transistor

(Source)

DVP08SM10N

8

100 ~ 120V AC

0

DVP08SM11N

8

0

DVP16SM11N

16

0

N/A

DVP08SN11R

0

8

DVP06SN11R

0

6

Relay

DVP08SN11T

24V DC

0

DC Type

Sink/Source

8

Transistor

25.2

90

60

ENGLISH

Specifications

Electrical Specifications

Model

Item

08SM11N

08SM10N

DVP16SM11N

08SN11R/T

08SP11R/T

16SP11R/T

DVP16SP11TS

06SN11R

Power supply voltage

24V DC (-15%~20%) (with DC input polarity reverse protection)

Motion specification

Within 5ms of the momentary power loss, the device will keep on operating

Power consumption

1W

2W

1.5W

1.5W

2W

2W

1.5W

Insulation resistance

> 5MΩ (all I/O point-to-ground: 500V DC)

Noise immunity

ESD (IEC 61131-2, IEC 61000-4-2): 8KV Air Discharge

EFT (IEC 61131-2, IEC 61000-4-4): Power Line: 2KV, Digital I/O: 1KV,

Analog & Communication I/O: 1KV

Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV

RS (IEC 61131-2, IEC 61000-4-3): 26MHz ~ 1GHz, 10V/m

Earth

The diameter of grounding wire shall not be less than that of L, N terminal of the power. When many PLCs

are in use at the same time, please make sure every PLC is properly grounded.

Operation/storage

environment

Operation: 0°C ~ 55°C (temperature), 50% ~ 95% (humidity), pollution degree 2

Storage:

-25°C ~ 70°C (temperature), 5% ~ 95%

(humidity)

Shock/vibration

immunity

International standards: IEC61131-2, IEC 68-2-6 (TEST Fc)/IEC61131-2 & IEC 68-2-27 (TEST Ea)

Weight (g)

162 / 141

146

154 / 146

141 / 136

162 / 154

151

200

I/O Point Specifications

Input Point

Input point type

DC

AC

Input type

DC (Sink or Source)

-

Input resistance

-

19Kohm/50Hz 16Kohm/60Hz

Input current/voltage

24V DC 5mA

85 ~ 132V AC, 50 ~ 60Hz

9.2mA ,110V AC/60Hz

Off

On: more than 16.5V DC

More than 79V AC

Active level

On

Off: less than 8V DC

Less than 30V AC

Response time

Approx. 10ms, 0 ~ 15ms adjustable from D1020 and

D1021

Off

On < 15ms

On

Off < 20ms

Circuit

isolation/operation

instruction

By photocoupler / LED On

Output Point

Output type

Relay-R

Relay-R (*1)

Transistor-T (Sink)

Transistor-T (Source)

Current specification

1.5A/1 point (5A/COM)

6A/1 point

55°C 0.1A/1 point

50°C 0.15A/1 point

45°C 0.2A/1 point

40°C 0.3A/1 point (2A/COM)

55°C 0.3A/1 point

(2A/COM)

Voltage specification

< 250V AC, 30V DC

< 250V AC, 30V DC

30V DC

30V DC

75VA (inductive)

240VA (inductive)

Maximum load

90W (resistive)

150W (resistive)

9W

9W

Response time

Approx. 10ms

Approx. 10ms

Off

On 15us

On

Off 25us

Off

On 15us

On

Off 25us

*1: Only applicable in DVP06SN11R.

Installation & Wiring

Terminals of DVP-Slim

DVP08SM11N DVP08SM10N DVP16SM11N

DVP08SN11R

DVP08SN11T

DVP08SP11R

DVP08SP11T

DVP16SP11R DVP16SP11TS DVP06SN11R

S/S

X0

X2

X5

X6

X7

X3

X1

X4

COM

X0

X2

X5

X6

X7

X3

X1

X4

S/S

X0

X2

X3

X1

S/S

X10

X12

X13

X11

X14

X15

X16

X4

X5

X6

X7

X17

C0

Y0

Y2

Y5

Y6

Y7

Y3

Y1

Y4

S/S

X0

X2

X3

X1

C0

Y0

Y1

C2

C1

Y2

C3

Y3

S/S

X0

X2

X3

X1

C0

Y0

Y2

Y3

Y1

Y4

Y5

Y6

X4

X6

X7

X5

Y7

S/S

X0

X2

X3

X1

UP

Y0

Y2

Y3

Y1

Y4

Y5

Y6

X4

X5

X6

X7

Y7

ZP

C0

Y0

C1

C2

Y2

Y1

C3

Y3

C4

C5

Y5

Y4

Connection

Step 1

Screw open the side cover of the extension unit,

and you will see the connection port.

Step 2

Lift the fixing clip by the screwdriver.

Step 3

Adjust the positioning hole of the MPU and the

extension unit. Meet the connection port on the MPU with

the extension unit to tightly connect the two.

Step 4

Fasten the fixing clip on the extension unit to

complete the connection.

Installation & Wiring

Install the PLC in an enclosure with sufficient space around it to allow heat dissipation (as shown in the figure below).

DVP

MPU

D

D

D

D

D > 50mm

How to install DIN rail

DVP-PLC can be secured to a cabinet by using the DIN rail of 35mm in height and

7.5mm in depth. When mounting PLC to the DIN rail, be sure to use the end bracket to

stop any side-to-side movement of the PLC and reduce the chance of wires being

loosen. A small retaining clip is at the bottom of the PLC. To secure PLC to the DIN rail,

place the clip onto the rail and gently push it up. To remove it, pull the retaining clip

down and gently remove the PLC from the DIN rail.

22-16AWG

< 1.5mm

Wiring

1. Use 22-16AWG (1.5mm) single or multiple core wire on I/O wiring terminals. The

specification of the terminal is shown in the figure on the left hand side. The PLC

terminal screws shall be tightened to 1.95kg-cm (1.7 in-lbs). Use 65/75°C copper

wires only.

2. DO NOT place the I/O signal wires and power supply wire in the same wiring duct.

Notes

DO NOT install PLC in an environment with

Dust, smoke, metallic debris, corrosive or flammable gas

High temperature, humidity

Direct shock and vibration

During the engineering

1. DO NOT drop tiny metallic conductor into the PLC when screwing and wiring.

2. There should be a margin of more than 50mm between the PLC and other control devices, and the PLC should be

placed away from high voltage wire and power equipment.

Arrangement of I/O Points

No matter the MPU with how many points you are using, the input point No. of the first connected extension unit has to

start from X20 and output point No. from Y20. The MPU is able to connect to maximum 14 digital extension units. The

connection of MPU and extension units is demonstrated in the figure below.

PLC

Model

Input

points

Output

points

Input point No.

Output point No.

MPU

SS/SA/SX/SC

8

4/6

X0 ~ X7, X10, X11 Y0 ~ Y5, X10, X11

EXT1

16SP11T

8

8

X20 ~ X27

Y20 ~ Y27

EXT2

08SM11N

8

0

X30 ~ X37

-

EXT3

06SN11R

0

6

-

Y30 ~ Y35

MPU

EXT1 EXT2 EXT3 EXT4

EXT4

08SP11R

4

4

X40 ~ X43

Y40 ~ Y43

The 3

rd

extension module 06SN11R will be regarded as 8-point output. The 2 output points of bigger No. will have no

actual corresponding output points.

The 4

th

extension module 08SP11R will be regarded as 8-point input/8-point output. The 4 input points and 4 output

points of bigger No. will have no actual corresponding input/output points. Therefore, it is suggested that they placed in

the end of the series connection to make the No. of I/I points continuous.

Input Point Wiring & Specification

There are two types of signals at input points, DC and AC, and there are two types of DC inputs, Sink and Source. The

wiring are as follows.

Sink Mode

+24V

0V

DC Power Supply

S/S

X0

X1

X2

Sink mode

Source Mode

+24V

0V

DC Power Supply

S/S

X0

X1

X2

Source mode

AC Wiring:

Wiring Loop

110V AC Input Specification

Input voltage

85 ~ 132V AC, 50 ~ 60Hz

Input resistance

19Kohm/50Hz, 16Kohm/60Hz

Input current

9.2mA 110V AC/60Hz

On/Off voltage level

79V 3.8mA/30V 2.5mA

Response time

15ms

85~ 132VAC

50/ 6 0H z

COM X0

X1

X2

DVP08SM10N

Pro x.

Sens or

Circuit isolation/operation instruction

By photocoupler / LED On

Relay Output Wiring Circuit (Sink):

1 DO NOT wire empty terminal •

2 Fuse

3 Reverse current protection diode*1

4 Manual exclusive output*2

5 Emergency stop: by external switch

6 Surge absorber*3

7 Inductive load

8 Incandescent light (resistive load)

9 DC power supply

MC2

MC1

9

10

C0

C1

Y0

Y4

C2

Y2

Y3

Y5

Y1

5

2

3

7

8

1

6

7

2

5

4

MC2

MC1

AC power supply

*1: There is no internal protection circuit in the output relay of the PLC; therefore when activating an inductive load, we

suggest you parallely connect a reverse current protection diode to extend the life of the contact.

- The diode has to be able to endure max. 5 ~ 10 times of load voltage.

- The positive current of the diode has to be bigger than load current.

*2: Manual exclusive output uses external circuit and forms an interlock, together with the PLC internal program, to ensure

safety protection in case of any unexpected errors.

*3: There is no internal protection circuit in the output relay of the PLC; therefore when activating an inductive load, we

suggest you parallely connect a surge absorber (0.1uF + “100ohm to 120ohm”) to reduce the noise on AC load and

extend the life of the contact.

Transistor Output Wiring Circuit (Sink):

1 DO NOT wire empty terminal •

2 Emergency stop

3 Fuse

4 Manual exclusive output*1

5 DC power supply

6 Incandescent light (resistive load)

7 Reverse current protection diode*2

8 Inductive load

M C2

M C1

C0

C1

Y0

Y4

C2

Y2

Y3

Y5

Y1

5

7

8

1

6

6

4

M C2

M C1

2

3

3

9

9 Resistive load

*1: Manual exclusive output uses external circuit and forms an interlock, together with the PLC internal program, to

ensure safety protection in case of any unexpected errors.

*2: Use a zener diode (39V) in the PLC to protect the transistor output. When activating inductive load, we sugget you

parallely connect a reverse current protection diode.

Transistor Output Wiring Loop (Source):

1 Y6,Y7 (refer to other wiring methods)

2 Emergency stop

3 Fuse

4 Manual exclusive output*1

5 DC power supply

6 Incandescent light (resistive load)

7 Reverse current protection diode*2

8 Inductive load

MC2

MC1

ZP

Y6

Y7

Y1

Y4

Y3

Y2

Y0

Y5

5

7

8

6

6

4

MC2

MC1

2

3

3

9

UP

1

9 Resistive load

*1: Manual exclusive output uses external circuit and forms an interlock, together with the PLC internal program, to

ensure safety protection in case of any unexpected errors.

*2: Use a zener diode (39V) in the PLC to protect the transistor output. When activating inductive load, we sugget you

parallely connect a reverse current protection diode.

注意事項

請在使用之前,詳細閱讀本使用說明書。

本機為開放型 (OPEN TYPE) 機殼,因此使用者使用本機時,必須將之安裝於具防塵、防潮及免於電擊/衝擊意外之外

殼配線箱內。另必須具備保護措施(如:特殊之工具或鑰匙才可打開)防止非維護人員操作或意外衝擊本體,造成危險

及損壞

交流輸入電源不可連接於直流類型之輸入/出信號端,否則可能造成嚴重的損壞,因此請在上電之前再次確認電源配線。

請勿在上電時觸摸任何端子。

產品簡介

謝謝您採用台達 DVP-SLIM 系列可程式控制器。DVP-SLIM 系列 6 ~ 16 點擴充,含主機最大數位輸入/輸出擴充分別可達

256

點。另備特殊模組(AD/DA/PT/TC/XA/PU)擴充功能,最多可擴充 8 台特殊模組。

產品外觀及各部介紹

1 電源、低電壓指示燈

2 機種名稱

3 擴充機固定扣

4 輸出/入端子

5 DIN 軌固定扣

6 擴充機定位孔

7 銘牌

8 擴充機固定扣

9 DIN 軌糟 (35mm)

EXTENSIO N

PORT

60

8

8

9

10

4

4

7

5

6

25.20

3

.0

0

9

0

.0

0

3

.0

0

3

1

2

3

POWER

D

V

P

-

L. V

擴充機連接口

3

.0

0

9

0

.0

0

6

5

8

6 0

3

.0

0

25 .2 0

2

7

3

3

1

4

4

POWER

L.V

EXTEN SION

PORT

9

10

8

●

●

●

●

●

D

V

P

-

機種型號

輸入單元

輸出單元

機種

電源

點數

形式

點數

形 式

尺寸 (mm)

外形參考

DVP08SP11R

4

4

DVP16SP11R

8

8

繼電器

DVP08SP11T

4

4

DVP16SP11T

8

8

電晶體

(Sink)

DVP16SP11TS

8

DC Type

Sink/Source

8

電晶體

(Source)

DVP08SM10N

8

100 ~ 120V AC

0

DVP08SM11N

8

0

DVP16SM11N

16

0

無

DVP08SN11R

0

8

DVP06SN11R

0

6

繼電器

DVP08SN11T

24V DC

0

DC Type

Sink/Source

8

電晶體

25.2

90

60

繁體中文

繁體中文

繁體中文

繁體中文

功能規格

電氣規格

機種

項目

08SM11N

08SM10N

DVP16SM11N

08SN11R/T

08SP11R/T

16SP11R/T

DVP16SP11TS

06SN11R

電源電壓

24V DC (-15% ~ 20%)

(具直流輸入電源極性反接保護)

動作規格

電源瞬間斷電 5ms 以內繼續運轉

消耗電力

1W

2W

1.5W

1.5W

2W

2W

1.5W

絕緣阻抗

5 MΩ 以上(所有輸出/入點對地之間 500V DC)

雜訊免疫力

ESD (IEC 61131-2, IEC 61000-4-2): 8KV Air Discharge

EFT (IEC 61131-2, IEC 61000-4-4): Power Line: 2KV, Digital I/O: 1KV,

Analog & Communication I/O: 1KV

Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV

RS (IEC 61131-2, IEC 61000-4-3): 26MHz ~ 1GHz, 10V/m

接地

接地配線之線徑不得小於電源端 L, N 之線徑(多台 PLC 同時使用時,請務必單點接地)

操作/儲存環境

操作:0°C ~ 55°C(溫度),50% ~ 95%(濕度),污染等級 2

儲存:-25°C ~ 70°C(溫度),5% ~ 95%(濕度)

耐振動/衝擊

國際標準規範 IEC61131-2, IEC 68-2-6 (TEST Fc)/ IEC61131-2 & IEC 68-2-27 (TEST Ea)

重量(約)(g)

162 / 141

146

154 / 146

141 / 136

162 / 154

151

200

輸入點規格

輸入點電氣規格

輸入點形式

直流

交流

輸入形式

直流(Sink 或 Source)

-

輸入阻抗

-

19Kohm/50Hz 16Kohm/60Hz

輸入電壓電流

24V DC 5mA

85~132VAC 50~60Hz

9.2mA 110VAC/60Hz

Off → On

:16.5V DC 以上

79V AC

以上

動作位準

On → Off

:8 V DC 以下

30V AC

以下

反應時間

約 10ms(由 D1020 及 D1021 可作 0 ~ 15ms 的調整)

Off

On < 15ms

On

Off < 20ms

電路隔離/

操作指示

光耦合器 / LED On

輸出點電氣規格

輸出點形式

繼電器-R

繼電器-R (*1)

電晶體-T (Sink)

電晶體-T (Source)

電流規格

1.5A/1

點 (5A/COM)

6A/1 point

55°C 0.1A/1

點、

50°C 0.15A/1

點、

45°C 0.2A/1

點、

40°C 0.3A/1

點 (2A/COM)

55°C 0.3A/1

點 (2A/COM)

電壓規格

250V AC, 30V DC

以下

250V AC, 30V DC

以下

30V DC

30V DC

75VA

(電感性)

240VA

(電感性)

最大負載

90W

(電阻性)

150W

(電阻性)

9W

9W

反應時間

約 10ms

約 10ms

Off → On 15us

On → Off 25us

Off → On 15us

On → Off 25us

*1:

僅適用於 06SN11R 機種