Ongrade process overview, Ongrade operator’s manual – Ditch Witch OnGrade User Manual

Page 27

Conduct OnGrade Bore - 26

OnGrade Operator’s Manual

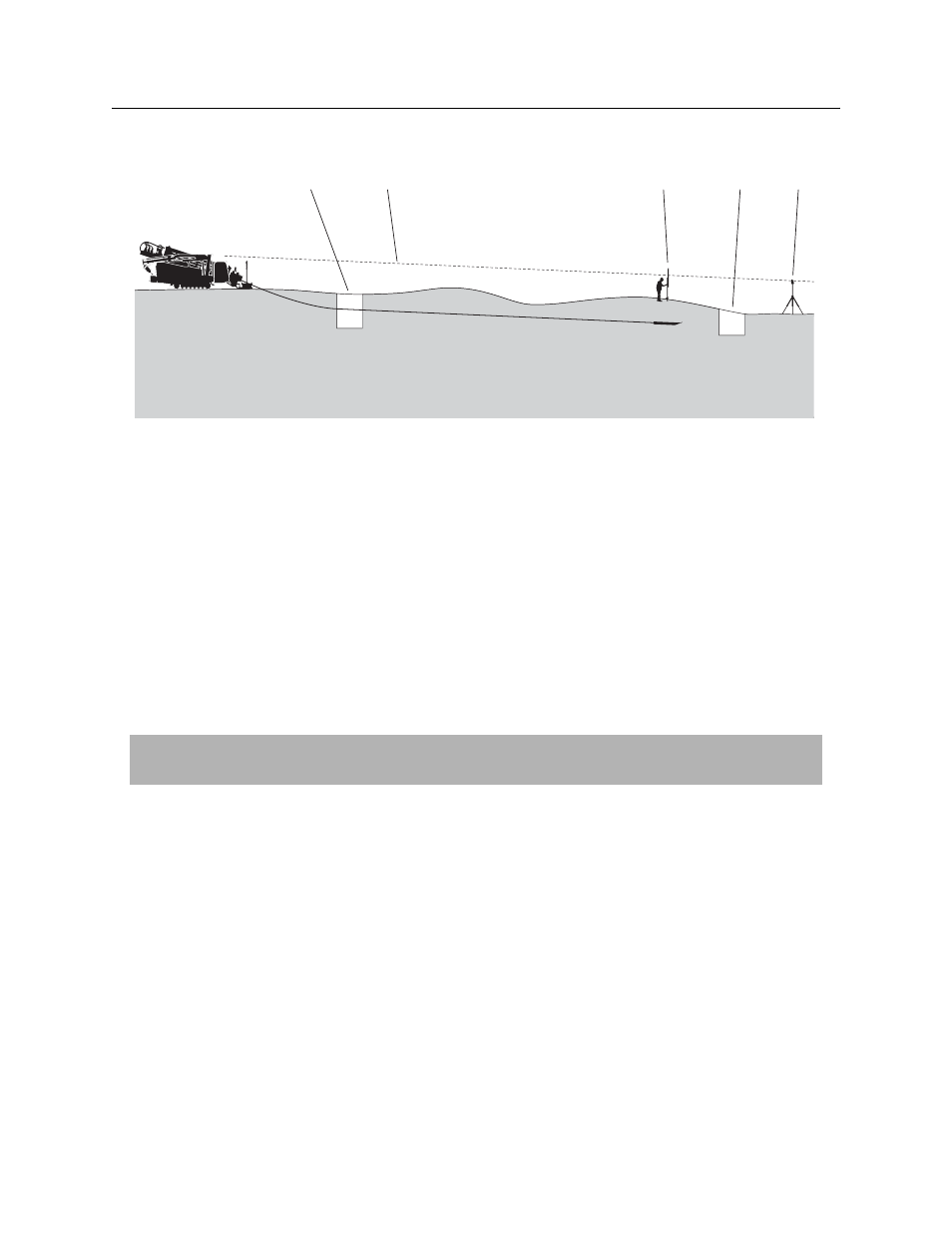

OnGrade Process Overview

CMW

OnGrade Process Overview

1.

Determine start and end pits. See “Job Plans” on page 38.

2.

Select downhole tools for pilot bore. See “Downhole Tools” on page 42.

3.

Calibrate system. See “Calibrate Depth, Roll, and Pitch” on page 29.

4.

Position drilling unit so that drill string is at the desired pitch and depth for at least one and a half drill

pipes before entering the start pit.

5.

Set up the tripod and laser past the end pit, if possible.

1.

start pit

2.

laser plane

3.

grade pole and tracker

4.

end pit

5.

tripod and laser

IMPORTANT: Grade pole can receive laser plane (2) from up to 600’ (183 m) in low-wind

conditions.

e14om005t.eps

1

2

3

4

5

See also other documents in the category Ditch Witch Special machinery:

- JT5 (161 pages)

- JT922 (159 pages)

- JT9 (165 pages)

- JT20 (195 pages)

- JT1220 (201 pages)

- JT2020 (203 pages)

- JT25 (203 pages)

- JT30 (245 pages)

- JT60 (218 pages)

- JT100 (243 pages)

- AT Air Hammer (11 pages)

- TK Series Manual (61 pages)

- 8500 (77 pages)

- MR90 (121 pages)

- FT5 (28 pages)

- FM5 (57 pages)

- FM13V (46 pages)

- FM25 (67 pages)

- P80 (71 pages)

- FX20 (100 pages)

- FX25 (119 pages)

- FX30 (149 pages)

- FX50 (141 pages)

- FX60 (157 pages)

- MV800 (111 pages)

- RT Line (115 pages)

- RT30 (97 pages)

- RT45 (203 pages)

- RT55 (177 pages)

- RT100 (161 pages)

- RT115 (252 pages)

- RT120 (223 pages)

- Zahn (105 pages)

- RT80 (203 pages)

- RT115 Q (193 pages)

- RT120 Q (211 pages)

- 100SX (50 pages)

- 410SX (131 pages)

- SK350 (77 pages)

- SK750/SK755 (81 pages)

- SK850 (107 pages)

- SK850 Footings Machine (107 pages)

- 150RT (55 pages)

- 250RT (49 pages)