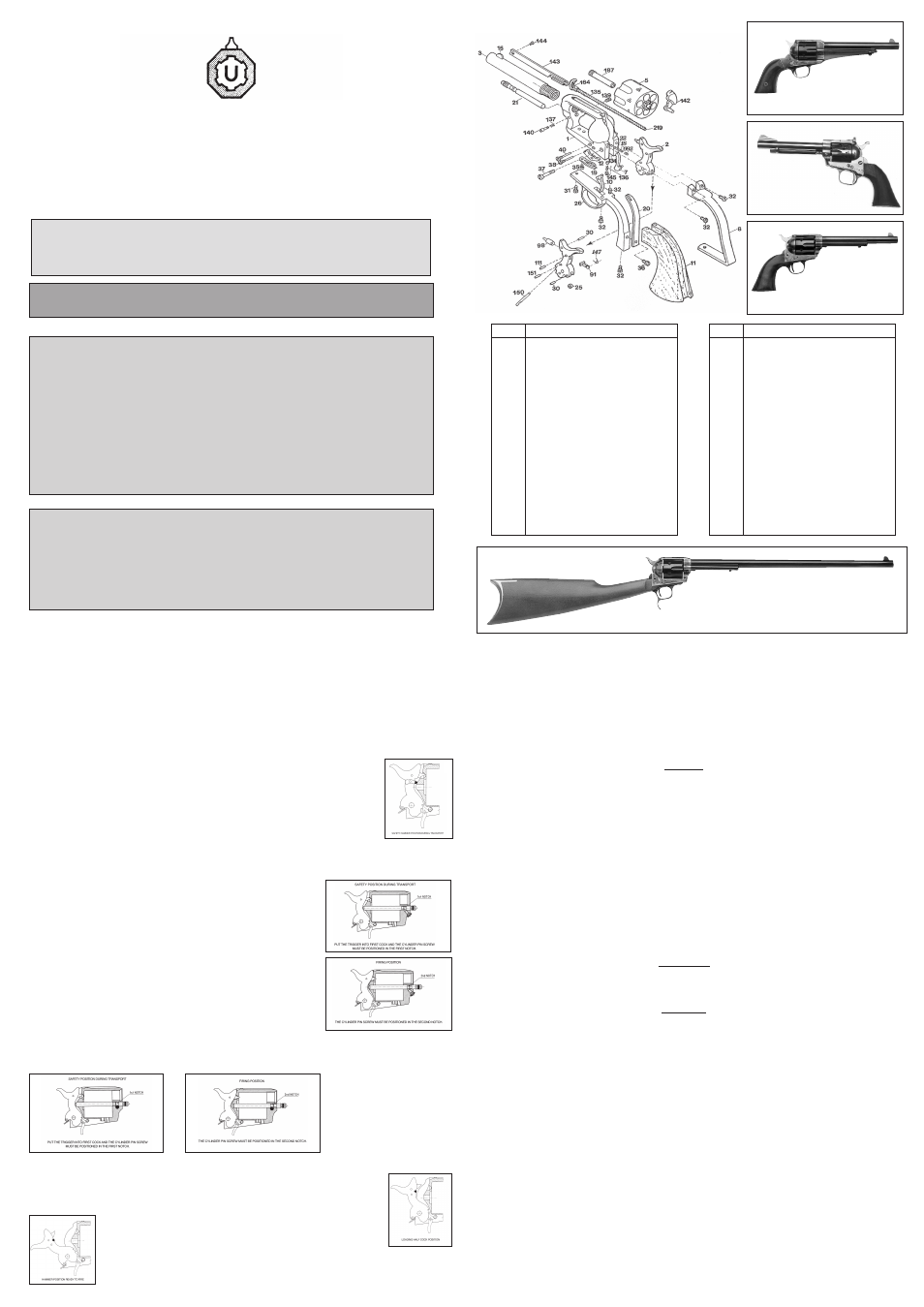

Uberti 1873 Single-Action Cattleman Revolvers User Manual

A. uberti, Instruction manual, Single action revolver and revolving carbine

SPECIAL SAFETY INSTRUCTIONS

1) DO NOT transport your Uberti revolver or carbine with a cartridge in the chamber.

Failure to observe this rule could result in an accidental discharge if the firearm is

dropped or knocked.

2) We advise that you DO NOT use old cartridges in these firearms because the

brass powder, after a certain period of time, can deteriorate and damage your

firearm which can be dangerous also for yourself.

3) NEVER use cartridges marked “High Speed” or “High Velocity”.

4) Uberti assumes no liability for incidents occurring through the use of reloaded

ammunitions.

Use ONLY COMMERCIALLY loaded cartridges that have been loaded in accor-

dance with SAAMI-C.I.P. standards.

SINGLE ACTION REVOLVER AND REVOLVING CARBINE

Instruction Manual

A. Uberti

S.p.A.

Via Artigiani, 1 - Gardone V.T. (Brescia) - ITALY

BEFORE REMOVING THE FIREARM FROM THIS PACKAGE,

READ & UNDERSTAND THE PRECAUTIONS IN THE

INSTRUCTIONS MANUAL

IMPORTANT

The old-timers used to say that the safest way to carry a single-action

revolver was to load only five chambers and let the hammer rest, in

the safety position , on the empty sixth chamber. That’s good advice

even today. It still takes proper care in handling and use by you, its

owner.

N.

PART.

1

FRAME

2

HAMMER

3

BARREL

5

CYLINDER

7

HAND

8

BACKSTRAP

10

TRIGGER

11

GRIPS

12

BOLT

15

FRONT SIGHT

18

HAND SPRING

19

SEAR AND BOLT SPRING

20

MAIN SPRING

21

BASE PIN

22

HAND SPRING PIN

25

HAMMER ROLL

26

TRIGGERGUARD

30

HAMMER PIN

31

TRIGGERGUARD SCREW

32

TRIGGERG. & BS. SCREW

35

BOLT SPRING SCREW

36

MAIN SPRING SCREW

37

HAMMER SCREW

N.

PART.

38

TRIGGER SCREW

40

BOLT SCREW

91

HAMMER SAFETY BAR

98

FIRING PIN

111

HAMMER SAFETY BAR PIN

134

GATE CATCH

135

EJECTOR SPRING

136

GATE SPRING

137

BASE PIN SPRING

139

BASE PIN NUT

140

BASE PIN SCREW

142

GATE

143

EJECTOR ROD TUBE

144

EJECTOR ROD TUBE SCREW

145

GATE CATCH SCREW

147

HAMMER SAFETY SPRING

150

HAMMER SAFETY PLUNGER

151

HAMMER SAFETY PLUNGER PIN

164

EJECTOR NUT

187

BASE PIN BUSHING

219

EJECTOR

692

HAND PIN SCREW

1873 S.A. STALLION

1875 S.A. ARMY OUTLAW

1873 S.A. CATTLEMAN

®

1873 S.A. CATTLEMAN

®

CARBINE

The term “single action” means that the hammer of your revolver must be manually drawn fully rearward, or “cocked”, before

firing each shot. In the process of cocking your revolver, you should note that there are three separate hammer positions, each one

having its purpose:

A. BASIC SAFETY, “AT REST” AND “TRANSPORT” POSITION

B. LOADING/UNLOADING POSITION (HALF COCK)

C. FIRING POSITION (FULL COCK)

Every model has a safety (first cock position) machined into the hammer. This is a voluntary safety and not an automatic safety;

please see instructions below (Drawings “A”). Always let the hammer rest on an empty or spent cartridge. Never rest the hammer

on a loaded cartridge. Never!!

A - BASIC SAFETY, “AT REST” AND “TRANSPORT POSITION”

Models with safety mechanism in the hammer.

These guns have a hammer block safety in the hammer. If you see a small slot at the rear of the hammer,

then your hammer has a safety already inserted. To activate the hammer safety block, pull the hammer rear-

ward until you hear the 1st click. Lower the hammer into the safety position. With the hammer in this posi-

tion, the hammer block safety mechanism is activated. This patented device places a steel insert between

the hammer and the frame and is designed to prevent the gun from firing accidentally. When the gun is not

being used, always use your hammer block safety. (See drawing ‘A’).

Models with safety mechanism in the cylinder base pin.

These guns have an elongated cylinder base pin, with two safety positions that function as a hammer safety block on both models,

old model frame (black powder) and new model frame (pre-war, modern).

OLD MODEL OR BLACK POWDER FRAME.

1. First, loosen the cylinder base pin screw in the frame.

2. Place the hammer in the safety notch position by moving the hammer rearward until

you hear the first click. When in the proper position, the hammer will rest

1

/

4

inch

from the frame.

3. Push the cylinder base pin into the frame as far as it will go. The stop ring on the

cylinder base pin will be against the front of the frame. The other end of the cylin-

der base pin will rest against the front of the hammer. (See drawing ‘A’)

4. Now you must tighten the cylinder base pin screw. Do not rely solely on this safety;

this is a voluntary safety and not an automatic safety.

PRE-WAR OR NEW MODEL FRAME

1. Place the hammer in the safety notch position by moving the hammer rearward until

you hear the 1st click. When in the proper position, the hammer will rest

1

/

4

inch from

the frame.

2. Depress the spring-loaded cross pin into the frame as far as it will go. Now you can

move the cylinder base pin.

3. Push the cylinder base pin into the frame as far as it will go. The stop ring on the cylinder base pin will be against the front

of the frame and the other end of the cylinder base pin will rest against the front of the hammer. (See drawing ‘A’)

4. Release the spring-loaded cylinder cross pin. Do not rely solely on this safety; this is a voluntary safety and not an automatic

safety

Activate and ALWAYS use your

hammer block safety when not

actually firing your revolver! It was

designed for your protection.

B - LOADING/UNLOADING (HALF COCK) POSITION

Draw the hammer back to the half cock position (you can also hear this click if you listen carefully). In

doing this, you actually disengage the cylinder allowing it to rotate freely in the direction of the loading

gate. This permits you to load or unload your revolver when you open the

loading/unloading gate on the rear side of the frame. (See drawing ‘B’)

C - FIRING (FULL COCK) POSITION

Draw the hammer full rearward to its full cock position. Make sure it clicks into this

rearmost position. Your revolver is now ready to fire. (See drawing ‘C’)

NOTE: Never attempt to fire your revolver in any position except the full cock position. Attempting to

pull the trigger in the safety position or half cock position will strain the mechanism and make it unsafe.

(It might even break if you are strong enough).

If you have your revolver in the full cock position and change your mind and don’t want to shoot, carefully follow these steps:

1. Point the revolver in a safe direction.

2. Fully draw the hammer back with your thumb and continue holding it fully rearward while pulling the trigger backward. Hold

the trigger and hammer back in this position.

3. While you keep holding the trigger back, slowly lower the hammer downward, past its half cock notch. Remember – you are

lowering it toward a live round! Be careful and keep it pointed in a safe direction.

4. When past the half cock notch, release pressure on the trigger and take your finger out of the trigger guard.

5. Continue to lower the hammer to its safety notch position.

LOADING

Keeping your finger out of the trigger guard and off the trigger, draw the hammer back to the half-cock position which makes the

cylinder free to rotate. Then open the loading gate as far as it will go. This will expose each chamber, one at a time, as you rota-

te the cylinder. Make certain you have the exact caliber cartridges matching the exact caliber of your revolver. Then load one car-

tridge in each chamber. Close the loading gate which, as you can see, becomes part of the recoil shield. Then place the hammer

in the safety notch position by drawing it back, allow the hammer to travel slowly forward, but only far enough to pass its half-

cock notch position, carefully pull the trigger back, and, holding it back, slightly to disengage it from its half-cock notch. Holding

the hammer back out of its half-cock notch position, carefully pull the trigger back, and, holding it back, allow the hammer to tra-

vel slowly forward, but only far enough to pass its half-cock notch. NOTE: You will not hear a click as it moves through the half-

cock notch. Then release the pressure on the trigger and continue to slowly lower the hammer forward until it clicks into its safe-

ty position. Again, you should practice this loading function without any cartridges until you are comfortable with handling the

hammer and are familiar with its respective notches. Then, and only then, are you and your revolver ready for use.

SPECIAL WARNING FOR CAL. 22

When loading the cylinder, be sure to push each cartridge fully into the chamber to avoid interference of the cartridge rim with

either the frame of the revolver or the loading gate. Failure to fully seat the cartridge and any attempt to force the cylinder to rota-

te or to force the loading gate closed could lead to possible detonation of the cartridge and injury to the shooter. Remember to

always keep the muzzle pointed in a safe direction when loading, and to close the loading gate after loading before handling fur-

ther. NEVER DRY FIRE your revolver. If you do this you will ruin your cylinder and the ammunition will not enter the cham-

ber in the correct way.

UNLOADING

Draw the hammer to its half-cock position and open the loading gate on the right rear part of the frame. Push out each cartridge

or empty case with the ejector rod located under the barrel. Operate the ejector rod in each chamber to its full length to assure full

length case ejection. Close the loading gate after you are sure that all six chambers in your revolver are empty.

CLEANING

Check first to make sure your revolver is empty. Then remove the cylinder using the following steps:

1. Open the loading gate.

2. Put the hammer in its half-cock notch.

3. Depress the base pin catch. This is the spring loaded plunger which is located on the left front side of the frame. Keep it

depressed.

4. Slide the base pin all the way out. The base pin is the heavy pin around which the cylinder revolves (and provides a bearing

surface for the cylinder). It should always be clean and lubricated.

5. Remove cylinder toward the loading gate.

The cylinder is made to fit your revolver precisely and can be removed and replaced easily, but carefully. It is a close fit, so don’t

force it to move in any direction. To reassemble, simply reverse the steps used in removal. When you reassemble the base pin,

make sure the base pin catch snaps back to its regular position. You can test this by making sure the plunger is free to move when

you depress it and it returns under its own spring pressure.

Use a wood, aluminum or brass cleaning rod (not steel), a brass bristle brush, and patches appropriate to your revolver’s caliber

to clean it. Use a good quality cleaning solution to scrub the bore and each cylinder. While scrubbing the bore, always brush all

the way through the bore; never try to reverse directions while the brush is actually in the barrel or chamber. After scrubbing, run

clean patches through the bore and chambers until they come out clean. Then completely, but lightly, oil the entire revolver. You’ll

find that the oil will nicely color the one piece grip of your revolver over the years, and it will develop and retain a soft patina

glow. Use a good quality brass polish on the back-strap and trigger guard. The brass parts are solid brass, and, as such, will tar-

nish, reflecting their good quality. It is easily removed with any good quality brass polish.

Use your revolver carefully and safely. Help us to help you keep and protect your right to gun ownership.

CAUTION - Remember, when you fullcock your revolver to shoot it again, you rotate the cylinder, you decide not to fire when

you decocked the pistol. This round is still live and will rotate back towards the firing position with each cocking. Do not forget

about this round.

If you fired rounds prior to the decocking operation and commence firing again, the hammer will fall on one or more empty cylin-

ders and still will fall on a live round. Be careful and attentive to this live round.

Always keep pistol pointed in a safe direction.

A

A

A

B

C