AquaCraft 18 Marine Engine User Manual

Page 2

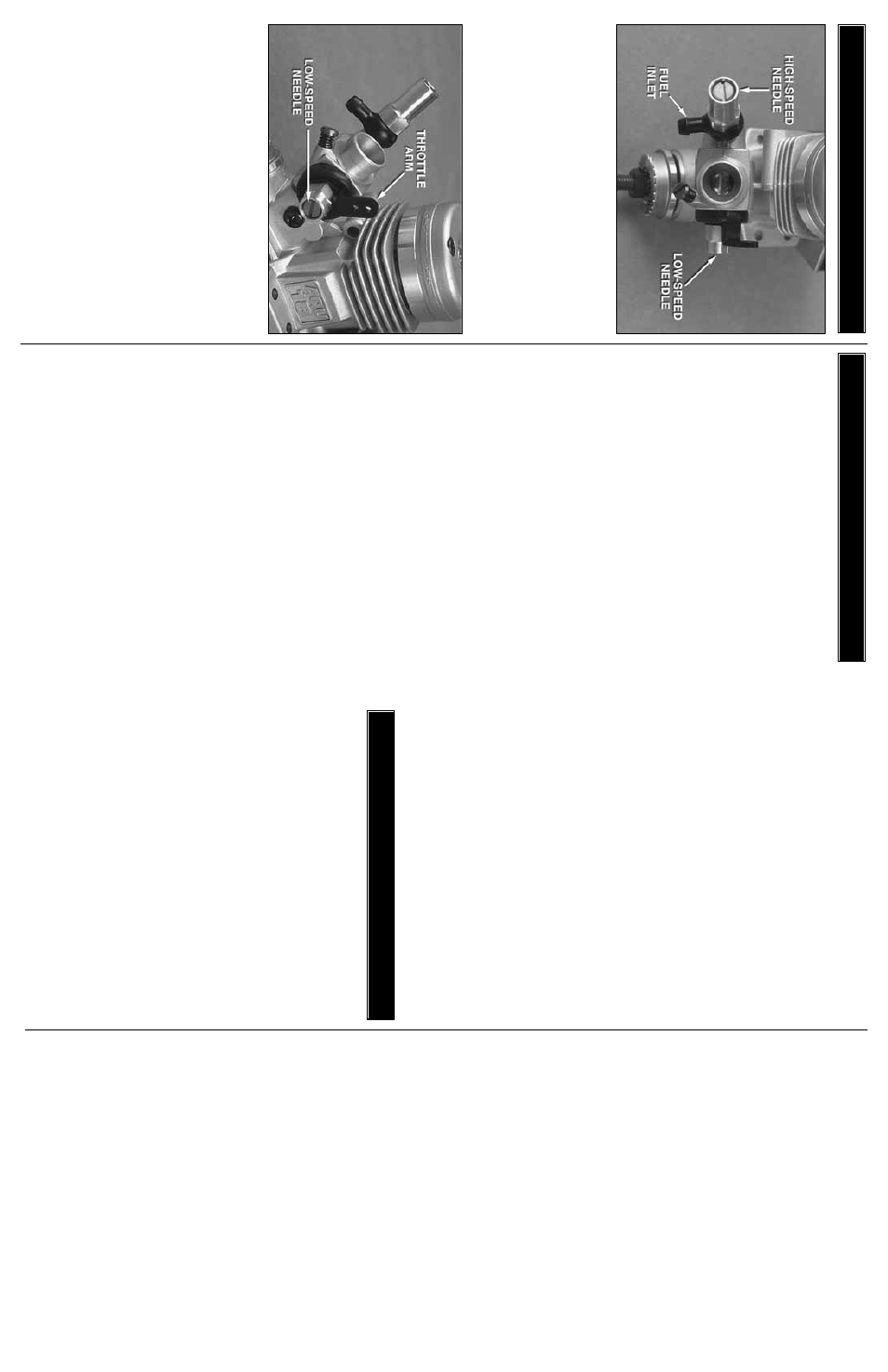

The High-Speed Needle

The

“high-speed”

needle is stic

king up from the side of the carb

.

It is located in the br

ass housing, just abo

v

e

the fuel inlet.

It

controls the fuel to air mixture of the carb

.The needle is pre-set

fo

r break-in from the f

a

ctor

y at 2 tur

ns out from the fully closed

position of the carb

.

Once the engine is brok

en-in, the high-

speed needle w

ould typically r

un from 1-1/4 to 1-3/8 tur

ns out

from closed (2 tur

ns to star

t break-in), depending on the

w

eather

, humidity and altitude abo

v

e

sea le

v

el.

T

o

r

ichen tur

n

the needle countercloc

kwise

, to lean tur

n

the needle cloc

kwise

.

The Lo

w-Speed Needle

The

“lo

w-speed”

needle is the scre

w in the carb body

, in the end

of the throttle ar

m.

It controls the fuel to air mixture at lo

w throttle

settings

.

There is a simple w

a

y of adjusting the lo

w-speed

needle correctly called the

“pinch test.

”

With the engine at idle

,

pinch the fuel line and listen to ho

w the engine speeds up or

slo

ws do

wn.

If the engine increases its speed f

o

r about 3 or 4

seconds and then loses speed, the needle is set correctly

.

If the

engine loses RPM quic

kly

, it is set too lean and the lo

w-speed

needle needs to be opened (countercloc

kwise) to r

ichen the

mixture

.

Pinch again to chec

k the mixture

.

If the engine tak

es

longer than 5 seconds to slo

w do

wn, lean (cloc

kwise) the lo

w-

speed needle and then pinch again to chec

k the mixture

.

The

Thr

ottle Stop Scre

w

T

u

rn

the throttle stop scre

w out 1 full tur

n

bef

ore installing the

engine in y

our boat.

The carb

uretor barrel should fully close with

the throttle ar

m fully bac

k.

Note:

This engine was designed to racing tolerances and

ma

y take long

er than 5 tanks to full

y break-in.

T

o

insure long lif

e and good perf

o

rmance from y

our AquaCr

aft

.18 engine

, y

ou

MUST

break-in the engine

.

The break-in per

iod

is cr

itical f

or long lif

e of the inter

nal par

ts of the engine

.

This

should be done o

v

er the first 5 or 6 tanks of fuel.

Some

Things

T

o

Remember During Break-In:

1.

Use the same fuel that y

ou will use f

or nor

mal r

unning.

2.

Resist the urge to acceler

ate and deceler

ate the boat quic

kly

.

3.

Break-in puts stress on the glo

w plug and y

ou can b

u

rn

it out

dur

ing break-in.

Mak

e sure y

ou ha

v

e

an e

xtr

a plug or tw

o

on hand.

Star

ting the Engine:

1.

Install a glo

w plug if one is not in y

our engine

.

This threads

into the top of the cylinder head.

2.

Fill the tank almost to the top

.

Lea

v

e

a little air at the top of

the tank.

3.

Pr

ime the engine b

y

co

v

e

ring the e

xhaust por

t and rotating

the flywheel on the engine

.W

atch the fuel go through the line

and when it gets to the carb

uretor

, tur

n the flywheel one more

full re

v

o

lution.

4.

Open the high speed needle v

alv

e 2 to 2-1/2 tur

ns out

(counter

c

loc

kwise)

from fully closed.

The high-speed

needle is stic

king up fr

om the carb

uretor inside the brass

housing.

All of the carb

uretor settings are adjusted with a flat

b

laded scre

wdr

iv

er

.

If y

ou ha

v

e

pre

v

iously r

un the boat, k

eep

the same needle v

alv

e setting that y

ou used on y

our last r

u

n.

5.

Star

t the engine b

y

pulling the recoil – use shor

t, quic

k

pulls

.

DO NO

T

pull the recoil star

ter’

s str

ing to the end.

6.

Once the engine is star

ted, open the high-speed needle

v

alv

e around 1/8 tur

n

at a time

, finding the setting where the

engine just barely r

uns

.

7.

Look at the smok

e that comes out the e

xhaust this is also a

good indicator of ho

w r

ich or lean the engine is r

unning.

If

there is a good amount of smok

e coming out of the e

xhaust,

then chances are good that y

ou are r

unning r

ich.

8.

Run the boat at a medium speed until the tank is almost out

of fuel.

Do not allo

w

the tank to r

un out of fuel.

This leans

out

the engine and can cause o

v

erheating (See

Ho

w T

o

Stop

Y

our

Engine

).

9.

Stop the engine and allo

w the engine to cool bef

ore the

second tank.

This nor

mally tak

es around 10 min

u

tes

.

If the engine does not star

t after se

v

e

ral pulls

, sometimes it is

helpful to star

t the engine at around half throttle

.

H

a

v

e a fr

iend

pull bac

k on the throttle some while y

ou star

t the engine

.

This

ma

y

be an indicator that the lo

w speed needle setting needs to

be adjusted.

When the engine star

ts

, immediately retur

n

the

throttle to idle

.

If this is not done the engine can o

v

er-re

v and

cause engine damage

.

If the engine is difficult to turn o

ver

with the recoil star

ter

,

especiall

y

if it is brand ne

w

,

loosen

the glo

w plug a half turn bef

o

re star

ting the engine

.

This

allo

ws some compression to escape

,

b

ut the engine will

BREAKING IN

THE ENGINE

CARB

URET

OR SETTINGS

still star

t.

Make sure y

ou tighten the glo

w plug after the

engine star

ts.

If the recoil star

ter is still difficult to pull, the

engine is flooded – there is too m

uch fuel inside the engine

.

Remo

v

e

the glo

w

plug and air cleaner

, then tur

n

the engine

upside do

wn and pull the recoil 5 or 6 times

.

This will clear the

engine of fuel, and y

ou will notice the recoil pulls easier

.Replace

the glo

w

plug and repeat the star

ting procedure

.

Fuels

Use fuels that are specially f

o

rm

ulated f

or mar

ine engines

.

O’Donnell Boat Fuel is specially f

o

rm

ulated f

or engines lik

e the

AquaCr

aft .18.

Stopping Y

our

Engine

Y

ou will need to stop y

our engine as the boat approaches shore

.

Its best to dr

iv

e y

our boat par

allel to the shore and tur

n the boat

in AFTER the engine quits

.

Mak

e sure bef

ore y

ou r

un y

our boat

fo

r the first time

, that when y

ou push the throttle tr

igger full bac

k

that the engine shuts off

.

Complete the Break-In

T

u

rn

in the needle v

alv

e (cloc

kwise) around 1/8 tur

n from the

pre

vious setting f

or each additional tank.

Y

ou should notice that

the engine will perf

or

m better dur

ing each r

un.

Stop the boat

per

iodically to chec

k f

or o

v

erheating.

If it is too hot, stop the

engine

.W

ait f

or it to cool, then open up the needle v

alv

e 1/4 tur

n

and restar

t.

After the 5th tank, y

ou should be near to the peak

perf

or

mance of the engine

.

Nine

W

a

ys

T

o

Ensure A Long Lif

e

Fr

om

Y

o

ur Engine:

1.

K

eep y

our engine clean.

Dir

t will act as insulation on an

engine

.

It will not be ab

le to shed heat as easily

.

2.

Do not o

v

er-lean y

our engine

.

3.

Do not r

un y

our engine with little or no load.

Don’t re

v the

engine up to full throttle with the boat out of the w

ater

.

4.

Do not o

v

erheat the engine

.

This goes along with k

eeping it

clean and not o

v

er-leaning the engine

.

5.

Mak

e sure y

ou use a fuel from a reputab

le man

u

facturer

,

such as O’Donnell Fuels

.

6.

A

v

oid using old fuels in the engine

.

A

lw

a

ys r

un all of the fuel

out of the engine

.

After r

unning f

o

r the da

y,

use an after-r

un

oil and w

o

rk

it into the engine b

y

tur

ning the flywheel or

pulling the engine recoil slo

wly

.

7.

Do not scr

atch the piston or cylinder slee

v

e

.

A

v

o

id jamming

something into the e

xhaust por

t when remo

ving or re-installing

the flywheel.

Use a special tool called a cr

ankshaft loc

king tool

(not included), which is installed in the glo

w plug hole

.

8.

Do not use silicone sealer on the engine joints

.

Silicone

sealer contains acetic acid, which is corrosiv

e if it gets inside

y

our engine

.

9.

T

emper

ature changes can cause condensation inside the

engine

.

Use an after-r

un oil to protect the inside of y

our

engine

.

S

tore y

our engine inside the house

, not in a gar

age

or shed where there will be temper

ature e

x

tremes

.

Glo

w Plug

The glo

w

plug is an item that will w

ear out and need

replacement from time to time

.

It is a good idea to remo

v

e

the

glo

w

plug bef

ore y

our first r

un, heat it and see ho

w w

ell it glo

ws

.

Y

ou should see a br

ight or

ange glo

w

from the filament.

If a coil

or tw

o will not glo

w or the plug will not glo

w at all, replace the

plug.

If the engine quits when y

ou remo

v

e the glo

w

star

ter

, the

plug might need to be changed, although this ma

y be because

y

ou are r

unning too r

ich and need to scre

w in y

our high-speed

needle some

.

Look at the glo

w plug when y

ou are r

unning the

engine

.

If y

ou see some b

u

b

b

les coming from around the plug,

replace the glo

w plug (copper) gask

et, or both the plug and

gask

et.

The only real w

a

y to test a glo

w plug is to replace it.

Mak

e sure y

ou ha

v

e

a spare plug or tw

o (Silv

er Spor

t Glo

w

Plug-DTXG3001) on hand when y

ou r

un the engine

.

Fuel

Fuel can go bad.

The main ing

redient in model fuel is methanol,

which can absorb w

a

ter out of the air

, so k

eep y

our fuel jug

capped at all times

.

S

tore y

our fuel out of the sunlight and in a

cool place

.

Bad fuel is one of the most difficult prob

lems to

diagnose in engines

.

If y

ou ha

v

e

tr

ied e

v

er

ything y

ou can think

of to remedy an engine that is not r

unning correctly

, tr

y using

some fresh fuel.

Maintenance

Fuel line is susceptib

le to pinhole leaks

.Y

ou cannot see the hole

in the fuel line

, b

u

t if y

ou see air b

u

b

b

les in the line going to the

carb

uretor

, replace the fuel line

.

Another symptom of a leak in

the fuel line is a surging engine

.

The proper

ly tuned engine will

surge when the air b

u

b

b

les hit the carb

.

It is basically leaning out

the mixture

.

T

o

k

eep dir

t out of the engine

, w

e

recommend that y

ou use an

inline fuel filter (Clean-Flo

w Fuel Filter-DTXC2551) on the fuel

line r

unning from the fuel tank to the carb

uretor

.

Dir

t can get

caught in the needle seat and cause an inconsistent r

unning

engine

.

If y

ou suspect that some dir

t has lodged itself in the

carb

, remo

v

e

the needles and clean the carb with denatured

alcohol or fuel.

It can help to use compressed air to b

lo

w

out the

fuel passages as w

e

ll.

ENGINE MAINTENANCE