Breaking in the engine, Starting the engine – AquaCraft 15 Marine Engine User Manual

Page 2

Water Cooling Lines

Connect the boat's water-cooling lines to the cylinder head using

medium silicone fuel tubing. It is important to make sure that the

water-cooling lines are unobstructed and allow water to flow directly

through the cylinder head. Once again, use a minimum of tubing

and be careful not to crimp the lines.

There are Several Simple Steps to Starting the Engine

1. Install a glow plug. The glow plug threads into the top of the

cylinder head. We recommend the O.S.

®

#8 glow plug (OSMG2691).

2. Fill the tank almost to the top. Leave a little air at the top of the tank.

3. Open the high-speed needle valve 2-1/2 turns out

(counterclockwise) from fully closed. The high-speed needle is

sticking out the left side of the engine (looking at it from behind the

prop). If you have previously run the engine, keep the same needle

valve setting that you used on your last run.

4. Prime the engine by lightly pulling the recoil handle with the intake

choked. Stop when you see the fuel reach the carburetor. This will

take approximately 2-3 pulls. DO NOT ENERGIZE THE GLOW PLUG

DURING THIS STEP. The quantity of fuel drawn into the engine by

priming is an important factor in starting the engine successfully.

5. Secure the glow starter onto the engine's glow plug.

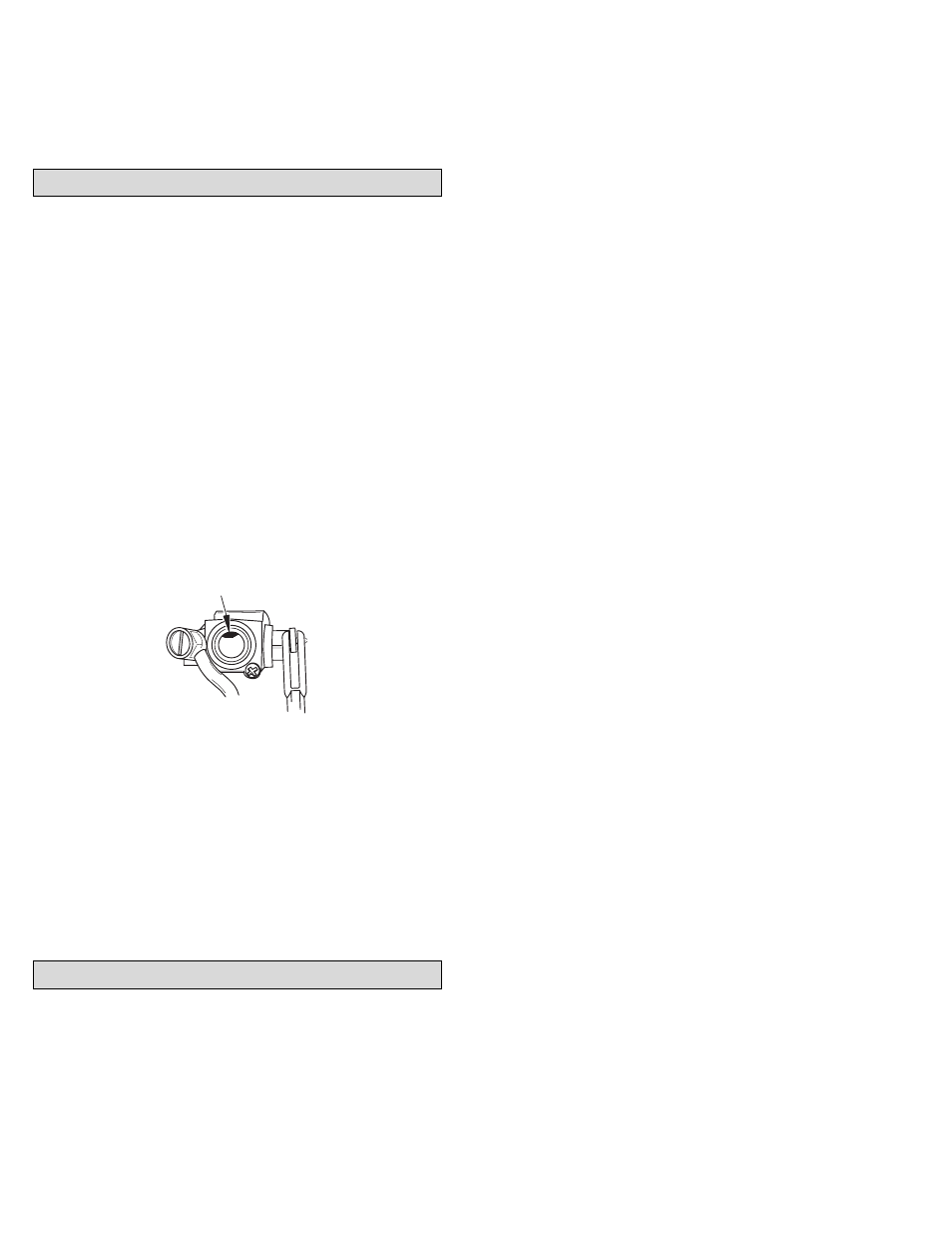

6. Check that the throttle is 1/8 open from the fully closed position.

Pull the recoil handle in quick strokes until the engine fires. If you pull

the recoil handle beyond 12-15 inches, you will damage your

engine. Repeat, if necessary. After 10 pulls, if the engine fails to start

there is a chance that there may not be enough fuel in the engine.

Remove the glow starter and repeat step 4. If the recoil becomes

difficult to pull, the engine has become flooded. If this occurs, simply

remove the glow plug and turn the engine upside down. Pull the recoil

handle 2-3 times and the excess fuel will drain out. Re-install the glow

plug, re-attach the glow starter, and try starting the engine again.

7. Once started, remove the glow starter after 10-15 seconds.

To insure long life and good performance from your AquaCraft Pro

.15 engine, you MUST break-in the engine. The break-in period is

critical for long life of the internal parts of the engine. This should be

done over the first 5 or 6 tanks of fuel.

Some Things to Remember During Break-In

1. Use the same fuel that you will use for normal running.

2. Resist the urge to accelerate and decelerate quickly.

3. Break-in puts stress on the glow plug and you can burn it out

during break-in. Make sure you have an extra plug or two on hand.

BREAKING IN THE ENGINE

Carburetor 1/8th open

STARTING THE ENGINE

The First Tank

Your first tank of fuel should be running the engine at a very rich

high-speed needle valve setting. This allows the fuel to carry as

much oil as possible into the engine to lubricate the internal parts

during the break-in.

1. Open the needle valve 2-1/2 turns out from fully closed

(counterclockwise). This is factory set already, but check it to make

sure. When closing the high-speed needle, close the needle until

you feel some resistance. DO NOT over tighten or you will damage

the engine.

2. Start the engine.

3. Once the engine is started, open the high-speed needle valve

around 1/8 turn at a time, finding the setting where the engine just

barely runs. This may take a few times adjusting the needle. The

engine will perform sluggishly and stall from time to time - this is

normal during the break-in process.

4. Place the boat in the water and run the engine at a medium

speed, periodically accelerating and decelerating. Do not give the

engine full throttle at this time.

5. Continue running the engine until the tank is almost out of fuel.

Do not allow the engine to run out of fuel. This leans out the engine

and can cause overheating.

Tanks 2-6

Turn in the needle valve (clockwise) around 1/8 turn each tank from

the previous setting. You should notice that the engine performs

better during each run. After the 6th tank, you should be near to the

peak performance of the engine.

Adjusting the Idle

From time to time you will have to make adjustments to keep your

engine running smoothly. Factors such as humidity, altitude, and

temperature will all affect engine performance. If your engine will not

idle smoothly, try adjusting the idle mixture screw. Start the engine

and let it run at idle. Pinch the fuel line. If the engine speeds up, the

mixture is too rich. Stop the engine and turn the idle mixture screw

clockwise 1/8 of a turn. Repeat this process until there is no change

when pinching the fuel line.

If the engine slows down when pinching the fuel line, the mixture is

set too lean. Richen the idle mixture screw 1/8 turn counterclockwise.

Once again, repeat this process until there is no change when

pinching the fuel line.

How to Stop Your Engine

Just as squeezing the throttle trigger on your transmitter increases

power, pushing the trigger the opposite way decreases power.

Pushing the throttle trigger forward should close off the throat of the

carburetor completely, cutting off air intake and stopping the engine.

If you are using a stick type transmitter, set the throttle trim so that

you can stop the engine by moving the throttle trim lever down to

close off the carburetor.

If the above methods fail, simply pinch the fuel line leading to the

carburetor. This will keep the engine from getting fuel and the engine

will stop.