Connectivity setup wizards mapped i/o waversaver, On-board diagnostics secure memory module (smm), In-weight) from a vessel to a – Hardy HI 3010 Filler/Dispenser Controller User Manual

Page 16: Connectivity, Setup wizards, Mapped i/o, Waversaver, Calibration, On-board diagnostics

3

CHAPTER 1

Overview

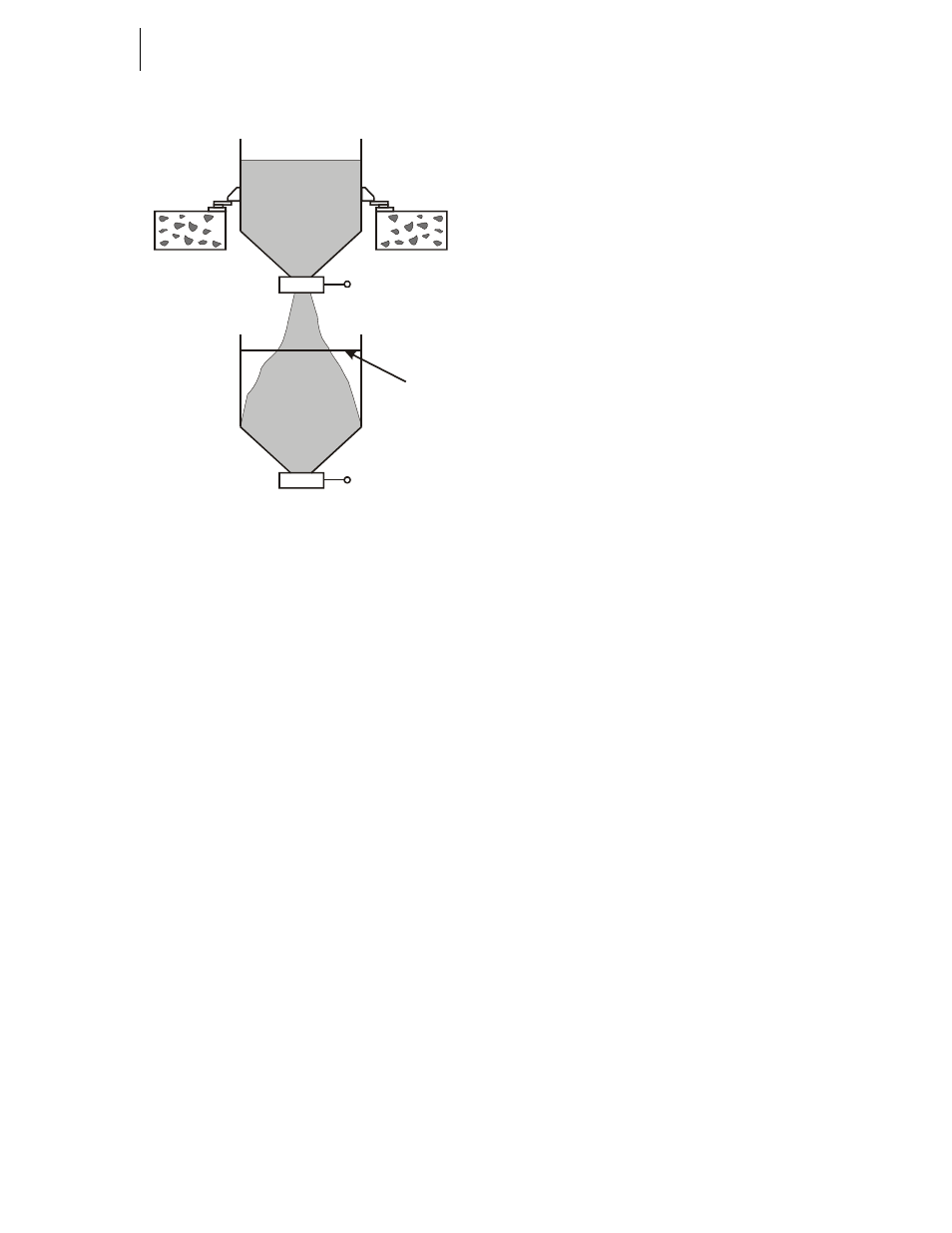

FIG. 1-4 DISPENSING (LOSS-IN-WEIGHT) FROM A

VESSEL TO ANOTHER VESSEL

Connectivity

All HI 3000 Series products enable the user to use the select-

able 10/100 base T Ethernet IP port or use its embedded web

server to link performance, diagnostics and setup data to and

from your intranet, extranet, VPN or the internet. Receive

alarms via e-mail or over WAP enabled devices including

cellular phones and PDA’s. A DeviceNet interface allows

multiple applications to be viewed and controlled from a dis-

play and additional 3rd party I/O to be easily added to the

filling/dispensing system. The controller has single RS-232

serial port configured as a printer port.

Setup Wizards

Setup Wizards enable the user to walk through the instru-

ment set up. On-board Help files are just a key press or click

away.

Mapped I/O

Mapped I/O saves wiring costs by distributing the I/O where

you need it, at the process or in the control room. The con-

troller is a DeviceNet Scanner and the DeviceNet Scan table

is configured using RS Networks

®

. Optional interfaces for

Allen-Bradley Remote I/O, Profibus provide communica-

tions to PLC and DCS systems.

WAVERSAVER

®

Typically, mechanical noise (from other machinery in a plant

environment) is present in forces larger than the weight

forces trying to be detected. The HI 3010 is fitted with

WAVERSAVER

®

technology which eliminates the effects of

vibratory forces present in all industrial weight control and

measurement applications. By eliminating the factor of

vibratory forces the controller is capable of identifying the

actual weight data. WAVERSAVER

®

can be configured

from the front panel to ignore noise with frequencies as low

as 0.25 Hz. One of four higher additional cut off frequencies

may be selected to provide a faster instrument response time.

The default factory configuration is 0.50 Hz vibration fre-

quency immunity.

C2

®

Calibration

C2

®

Electronic Calibration enables a scale system to be cali-

brated electronically without using certified test weights

which equals the systems load capacity. A C2 weighing sys-

tem consists of up to eight load sensors, a junction box, inter-

connect cable and an instrument with C2 capabilities, such

as the Filler/Dispenser/IBC. All Hardy C2 certified load sen-

sors contain digital information detailing its unique perfor-

mance characteristics. The Hardy Filler/Dispenser/IBC reads

the performance characteristics of each individual load sen-

sor and detects the quantity of load sensors in the system.

Calibration is performed by simply adding a reference point

from the front panel, or via the Web Server. The reference

can be zero (no weight on the scale) or alternatively, a

known weight on the scale. The instrument is capable of per-

forming traditional calibration such as with the use of certi-

fied test weights.

NOTE:

WAVERSAVER

®

and C2

®

are registered trade-

marks of Hardy Process Solutions Inc.

On-Board Diagnostics

The HI 3010 has a built in diagnostics utility which enables

the operator to rapidly troubleshoot a weighing system from

the front panel of the controller or via the Web Server. Sim-

ply press the Test button and scroll through several tests that

will furnish the current state of each of the parameters that

concern your application and the weigh system. Help is just

a click away in the event you should not understand the

information on the display or need a description of the

parameter.

Secure Memory Module (SMM)

The Secure Memory Module stores critical configuration (up

to 12 material configurations), calibration and setup data of

the HI 3010 Filler/Dispenser/IBC, thereby protecting this

information from corruption. During system operation when

a new parameter is entered, the SMM automatically updates

the value in its memory. Data stored in one HI 3010 can be

restored in another HI 3010 by physically transferring the

SMM to the new instrument. The SMM is conveniently

accessible from the instruments rear panel.

Load Point

Load Point

Dispense Gate

Discharge Gate

Target Weight