Rebuilding the differential, Disassembly, Reassembly – Losi LOSB0208BD User Manual

Page 10: Changing the spur gear, Changing the pinion gear/gear ratio, Setting the gear mesh

Rebuilding the Differential

The gears in the differential will wear over time. The same

is true for the outdrives, driveshafts, and rear axles. We

suggest using a small rag or paper towel to lay out the parts

you remove to make it easier to reassemble.

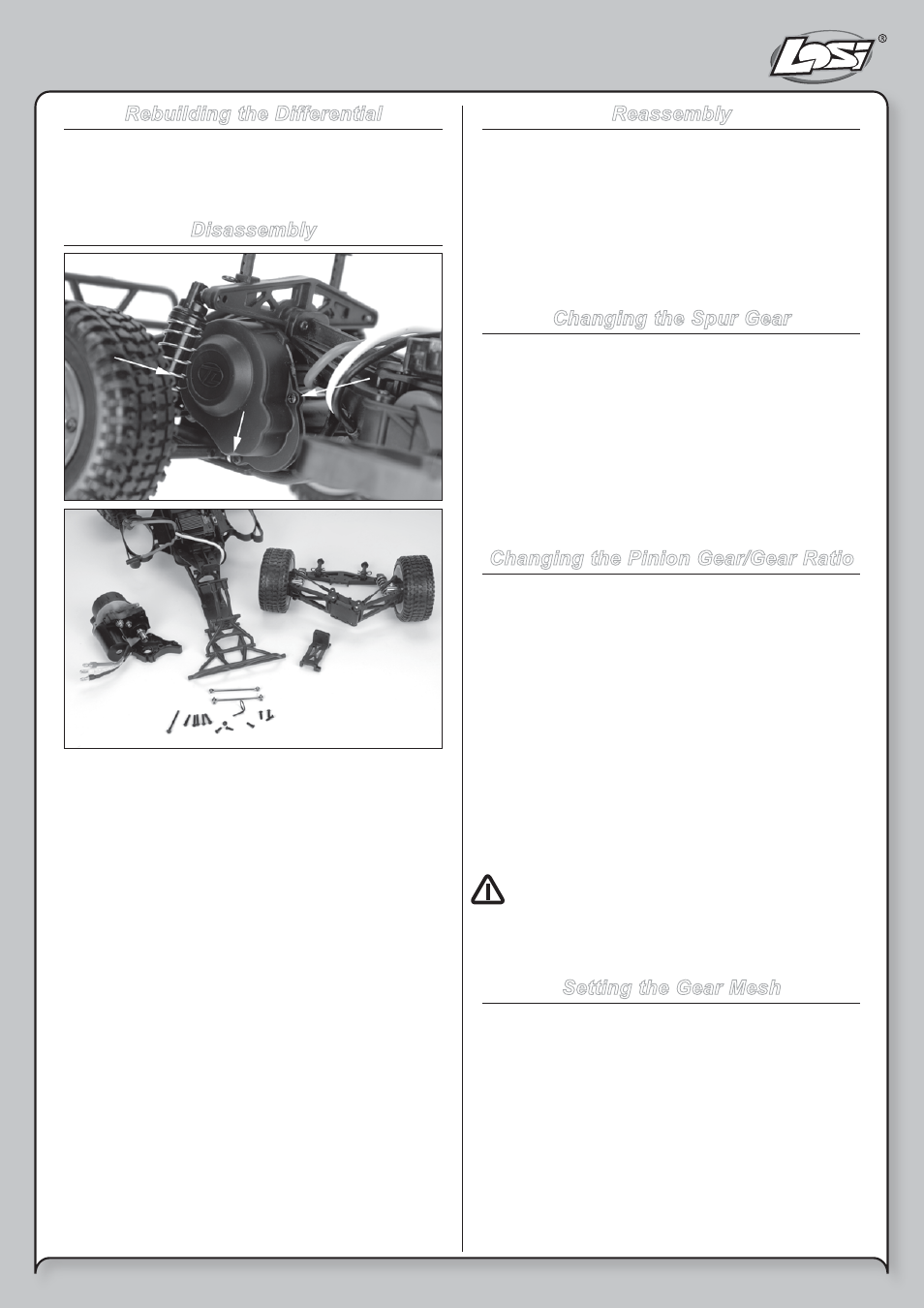

Disassembly

1. Unplug the 3 motor wires from ESC.

2. Remove the gear cover (three screws pictured)

3. Remove the 2 screws on the front of the rear shock

tower that attach to the rear upper cage. Once the

screws are removed, rotate the rear cage toward the

rear enabling access to the rear camber block.

4. Remove the 2 screws attaching the rear camber block to

the transmission case.

5. Remove 4 screws from rear skid plate and remove

transmission from vehicle.

6. Remove bracket on top of transmission by removing the

2 front screws and removing the long screw (secured

with a bolt), which passes through the transmission from

the motor plate side.

7. Remove the left side of the gearbox by removing the

three screws.

8. Remove any shims on the bevel gears (not used on all

models) and set them aside so they can be reinstalled in

the same location.

9. Carefully remove the large plastic sun gear and the

bevel gears on either side of it. You can use the

removed differential assembly as a guide for putting

together the replacement unit. For the best performance

Losi Grease (LOSA3066) can be applied to these gears.

10. Remove the center mounted idler gear from the

gearbox. Remove the shaft and push the ball bearings

out of both sides. Install these bearings in the new gear.

Reassembly

Replace the idler gear and shaft into the center of the same

right side of the gearbox. Replace any shims removed from

the right bevel gear and slide it through the lower bearing.

Replace any shims that came off of the left side bevel gear

and allow it to slide through the lower bearing as you put the

left gearbox half back into position. Replace the screws and

reinstall the rebuilt gearbox using the above steps in reverse

order. Consult the exploded view in the back of this manual

for more details.

Changing the Spur Gear

Remove the gear cover by removing the three small screws.

If you are replacing the spur gear with one of a different size

(number of teeth), you must first loosen (do not remove) the

two screws that secure the motor and slide it back slightly.

Remove the 3mm nut at the end of the slipper shaft and all

of the slipper parts on the outside of the spur gear as well

as the old gear. Place the new spur gear into position and

replace the slipper parts. If you have changed the size of

the spur, see Setting the Gear Mesh below. After you have

changed the spur gear, you will have to adjust the slipper as

described elsewhere.

Changing the Pinion Gear/Gear Ratio

Before you change the pinion gear ask yourself why you are

doing it. In general, if you change to a larger pinion the top

speed will improve but you will see less acceleration and

run time. This would only be advisable for really long track

layouts with few tight turns. Changing to a smaller pinion

will give you quicker acceleration and possibly a bit longer

run time but a little less top speed. This would be good for

short layouts or when running hotter motors. The pinion on

the Mini SCT offers the best balance of both. To change the

pinion, remove the gear cover, loosen the motor screws, and

slide the motor back. Use a pair of small needle-nose pliers

between the motor plate and back of the pinion to push the

pinion off. Place the new pinion on the end of the motor shaft

and, using the flat of the pliers or a similar flat tool, push it

on to the same position as the one removed. See Setting the

Gear Mesh below.

CAUTION

: When running aftermarket motors, check

with the motor manufacturer for correct gearing. Never

over-gear the motor as it can cause overheating, damaging it

and the speed control.

Setting the Gear Mesh

The motor screws should be slightly loose. Slide the motor

forward allowing the pinion gear to mesh with the spur gear.

Snug (not tight) the bottom motor screw and try rocking the

spur back and forth. There is a slight bit of movement before

the motor is forced to turn over. If not, pull the top of the

motor back slightly and recheck. If there is too much slop

between the gears, push the top of the motor forward. When

set properly, the wheels can be spun forward freely with

very little noise. Make sure to tighten both motor screws and

replace the gear cover before running.

10