Trouble shooting, Troubleshooting – Craftsman 113.225931 User Manual

Page 23

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

trouble shooting

WABWING: FOR YOUR OWN SAFETY, TURN

SWITCH "OFF" AND REMOVE PLUG FROM

POWER SOURCE OUTLET BEFORE TROUBLE

SHOOTING YOUR SANDER,

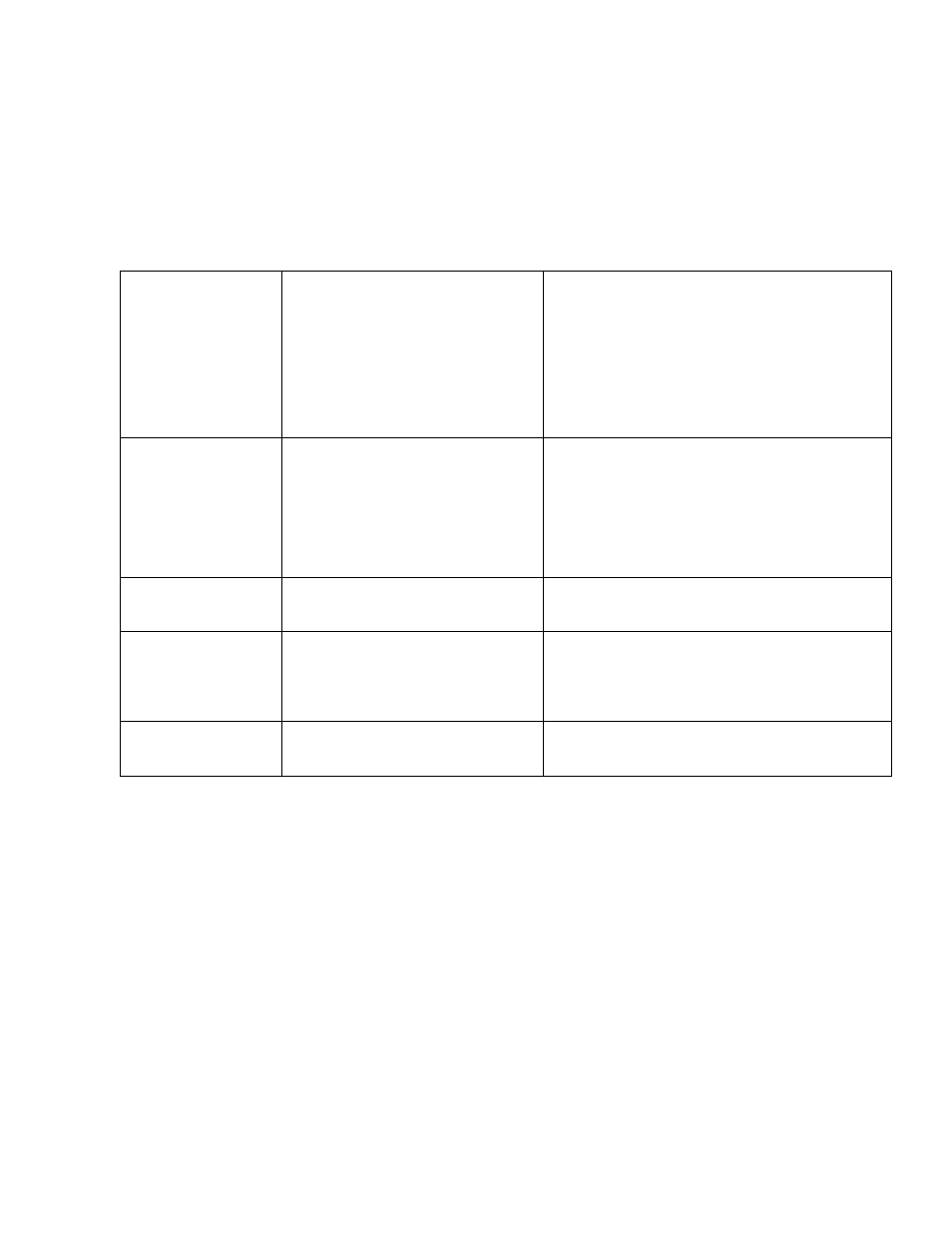

TROUBLE SHOOTING CHART

TROUBLE

Motor wit! not run.

PROBABLE CAUSE

1. Defective On-Off switch.

Defective switch cord.

Defective switch box receptacle,

2. Motor protector open, (only if

your motor is equipped with an

overload protector),

3 . B u r n e d o u t m o t o r .

REMEDY

1.

R e p l a c e d e f e c t i v e p a r ts b e f o r e u s i n g b e l t

disc

Sander

a g a i n .

2 .

R e s e t p r o t e c t o r a f t e r m o to r h a s c o o l e d .

3 . C o n s u l t S e a 's S e i v i c e . A n y a t t e m p t t o r e p a i r t h i s

m o t o r m a y c r e a t e a H A Z A R D u n l e s s f i r p a i r i s

d o n e b y a q u a l i f i e d s e r v i c e t e c h n i c i a r , . R e p a i r

s e r v i c e i s a v a i l a b l e a t y o u r n e a r e s t S e a r s S t o r e .

Machine slows down

when finishing.

1. V-Belt too loose.

2. Applying too much pressure to

workpiece.

3. Too much tension on abrasive

belt.

1. Increase belt tension, see Assernbly Section,

"Motor Pulley Belt Guard and Motor

Installation."

2. Ease up on pressure.

3. Adjust tension, see Assembly Section, "Installing

and Adjusting Abrasive Beit."

Abrasive Belt Slips

1. Not enou^ tension.

1. Adjust tension, see Assembly Section, "Installing

and Adjusting Abrasive Belt."

Abrasive Belt runs

off pulleys.

1. Not tracking properly ,

2. Not enou^ tension.

1, Adjust tracking, see Assembly Section, "Instaliirrg

and Adjusting Abrasive Belt."

2. Adjust tension, see Assembly Section, "installing

and Adjusting Abrasive Beit."

Wood burns while

finishing.

. . .

1. Abra&ive disc or belt is glaz^ with

sap.

1, Replace disc or belt.

23