To remove belt guard (see fig. 22), To replace ground drive belt (see figs. 22 and 23), Ground drive belt adjustment (see fig. 23) – Craftsman 917.295651 User Manual

Page 16: Service and adjustments

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE AND ADJUSTMENTS

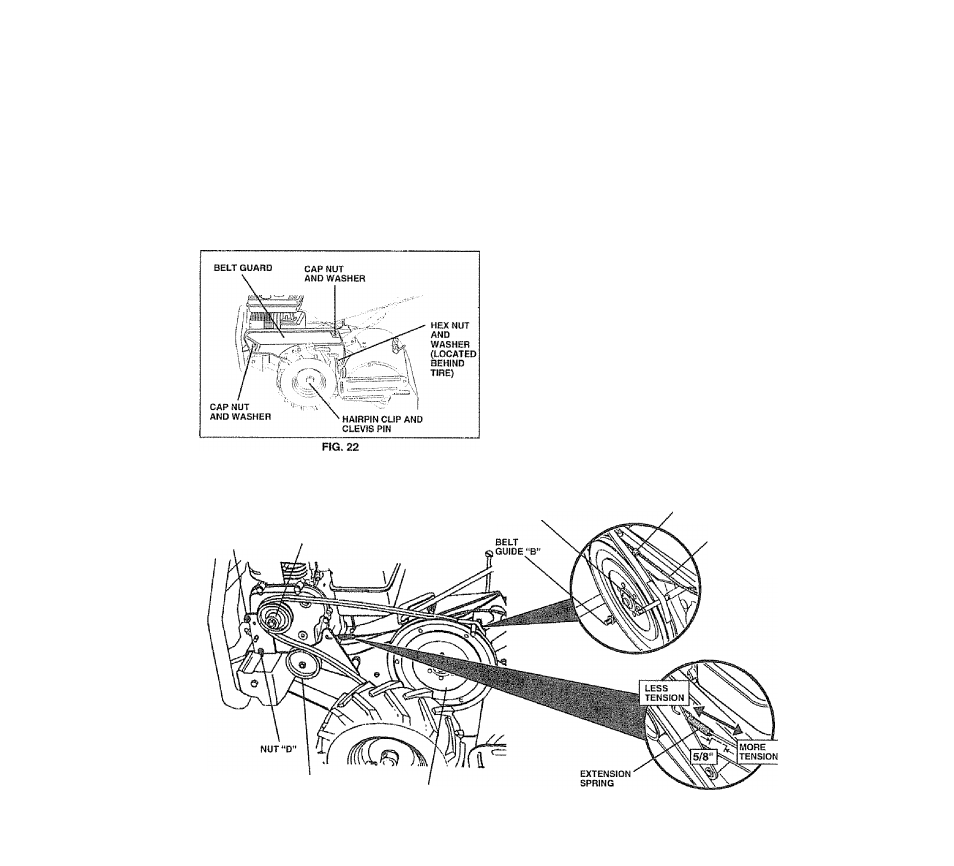

TO REMOVE BELT GUARD (See Fig. 22)

■* Remove L.H, inner and outer side shields (See "TO

REMOVE WHEEL" in this section of this manual).

«

Remove hairpin dip and clevis pin from left wheel. Puii

wheel out from tiiier about 1 inch,

"

Remove two (2) cap nuts and washers from side of belt

guard.

•

Remove hex nut and washer from bottom of belt guard

(located behind wheel).

" Puii belt guard out and away from unit,

“ Replace belt guard by reversing above procedure.

TO REPLACE GROUND DRIVE BELT (See

Figs. 22 and 23)

® Remove belt guard. (See‘TO REMOVE BELT GUARD"

in this section of this manual).

" Loosen belt guides "A" and *'B" and also nuts “C” and

* Remove oid belt by slipping from engine puiley first.

“ Place new belt in groove of transmission pulley and

into engine pulley . BELT MUST BE IN GROOVE ON

TOP OF IDLER PULLEY. NOTE POSITION OF BELT

TOf^i

* Tighten belt guides "A" and "B" and nuts

“C"

and “D”.

" Check belt adjustment as described beiow,

“ Replace belt guard.

= Reposition wheel and replace clevis pin and hairpin

ciip.

“ Replace inner and outer side shields.

GROUND DRIVE BELT ADJUSTMENT (See

Fig. 23)

For proper belt tension, the extension spring should have

about 5/8 inch stretch when drive control bar is in "EN

GAGED” position. This tension can be attained as follows:

® Loosen cable ciip screw securing the drive control

cable,

® Slide cable forward for less tension and rearward for

more tension until about 5/8 inch stretch is obtained

while the drive control bar is engaged.

® Tighten cable dip screw securely.

NUT"C"

ENGINE

PULLEY

BELT

GUIDE “A”

. CABLE CLIP

SCHEW

DRIVE

CONTROL

CABLE

IDLER

PULLEY

TRANSMISSiON

PULLEY

F!G. 23

16