Service and adjustments, Engine speed, Carburetor – Craftsman 580.327071 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE AND ADJUSTMENTS

ENGINE SPEED

CAUTION: Engine speed was properly adjusted at

the factory and should require no additional adjust

ment Do not attempt to change engine speed. If

you believe the engine is running loo fast or too

slow, take your generator to an authorized Sears

Service Center for repair and adjustment CHANG

ING ENGINE GOVERNED SPEED WILL VOID EN

GINE WARRANTY.

Th speed of the generator is maintained by an electronically

controlled governor. DO NOT try to adjust the governed

speed setting for the foliowing reasons:

•

High engine speeds are dangerous and increase the

risk of personal injury or damage to equipment,

•

Low engine speeds impose a heavy load orr the engine

when sufficient engine power is not available and may

shorten engine life

•

The generator will supply correct rated AC trequency

and voltage only at the proper speed Some connected

electrical devices could be damaged by incorrect fre

quency and/or voltage,

CARBURETOR

You may need to adjust the carburetor to compensate for

differences in fuel, temperature, altitude or load Air

cleaner and air cleaner cover must be assembled to carbu

retor when you run the engine

NOTE: DO NOT remove the air cleaner when running the

engine Operation without the air cleaner fully assembled

and the air filter installed may cause engine damage

INITIAL ADJUSTiWIENT

•

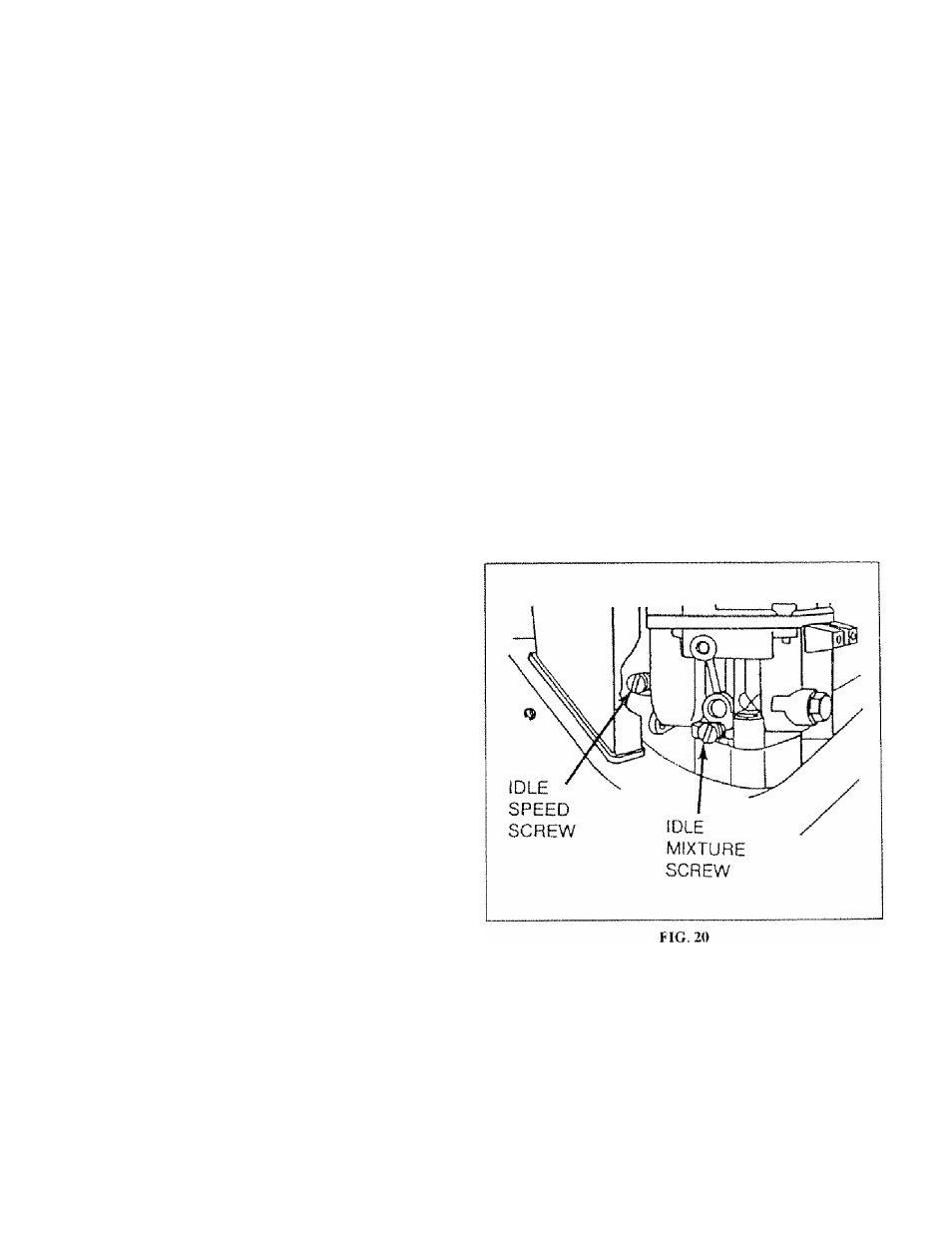

Gently turn IDLE MIXTURE valve (Fig 20) clockwise

until it just closes DO NOT FORCE Valve may be

damaged by turning it inward too far

o Next open IDLE MIXTURE valve 1-3/4 turns counter-

cloctavise

•

This initial adjustment will permit the engine to be

startsd and warmed up

FINAL ADJUSTMENT

•

Start engine and let it warm up for at least five minutes

» Hold the throttle against its idle stop (idle speed) and

then turn the IDLE MIXTURE valve slowly clockwise

1/8 turn at a time until the lean dropoff point is reached

(engine starts to miss and run erratically) Now turn the

IDLE MIXTURE valve counterclockwise until engine

speed begins to slow again (rich dropoff point)

•

Turn the valve to mid point between rich and lean

If further adjustment is needed, the main adjustment should

be made under a load condition as outlined under LOAD

ADJUSTMENT

I DAD Afl.Hl'iTMFNT

•

Let engine accelerate to normal governed speed,

•

Apply electrical loads to the generator at or near the

unit's full rated wattage/amperage capacity

•

If the engine stops or hesitates under load, open the

IDLE MIXTURE screw 1/8 turn at a time. Test each

setting with the engine under load until engine runs

smoothly,

•

If engine smokes excessively, turn the IDLE MIXTURE

SCREW clockwise 1/8 turn at a time until condition is

corrected,

•

After IDLE MIXTURE SCREW is property sat, move

throttle to idle speed position. If engine does not idle

smoothly turn IDLE SPEED SCREW 1/8 turn at a time

(either direction) until engine runs smoothly

NOTE: Engines operated at altitudes at about 5000 feet or

higher may require that you install a high altitude carburetor

main jet (Part No 80883) to achieve best engine perform

ance If engine performs erratically, contact your Sears

Service Certter to install the high altitude jet

n