Adjust wheel to disc, Adjusting wheel to disc – Great Plains 25P Eliminator Bushing Field User Manual

Page 5

Adjust Wheel to Disc

Great Plains Manufacturing, Inc.

5

11/15/2010

498-255M

Adjust Wheel to Disc

Adjusting Wheel to Disc

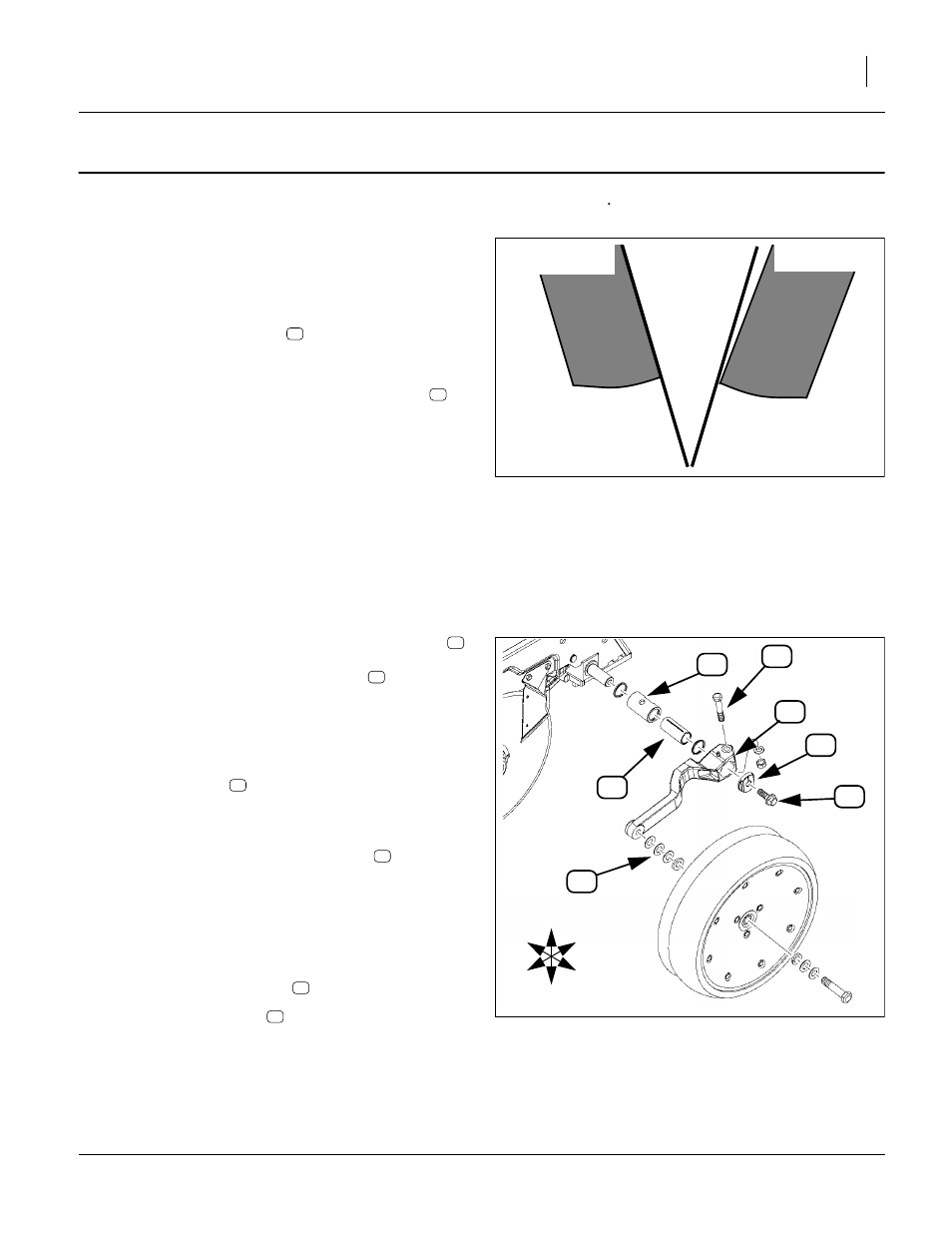

Refer to Figure 7 and Figure 8

Hex Head Adjuster

Check tire to disc contact location. Wheel should hit disc

at bottom of tire. At top of tire it should have

3

⁄

8

gap away

from disc. Adjust hex adjuster

to obtain correct con-

tact location.

19. Move wheel arm in so side gauge wheel contacts

row unit disc at bottom. Tighten hex-head bolt

to

clamp arm around bushing and shank.

Wheel and disc should touch but not be so tight

there is pressure. Pressure will cause it to bind up.

Allow for enough movement. Check wheel-to-disc

contact at 2in (5cm) planting depth. Lift wheel 2in

(5cm) and release. When let go, wheel should fall

freely.

If wheel does not contact disc at bottom to area

where blade leaves contact with soil, move hex

adjuster until wheel is angled for proper contact with

disc.

20. If wheel does not fall freely, loosen hex-head bolt

and slide wheel arm out just until wheel and arm

move freely. Retighten hex-head bolt

per grade:

1

⁄

2

in Grade 5 bolt, 76 ft-lbs (105 N-m).

1

⁄

2

in Grade 8 bolt, 110 ft-lbs (150 N-m).

21. Keep turning hex adjuster and moving wheel arm

until the wheel is adjusted properly. When satisfied,

tighten pivot bolt

to 110 ft-lbs.

Shims

22. If wheel does not contact blade when arm is slid into

end of bushing, then adjust the shims

. Remove

shim from behind wheel to move tire closer to blade.

23. Retain removed shims by placing them on the outer

side of the gauge wheel bolt so there is always

access to them for any future adjustments.

Finish

24. Tighten the hex-head bolt

.

25. Then tighten pivot bolt

(roughly

1

⁄

4

in gap at top of

wheel).

Incorrect

Correct

Null4:

Figure 7

Disc/Gauge Wheel Alignment

Side Gauge

Wheel

Opener

Discs

Side Gauge

Wheel

32

36

36

25

32

28

U

D

F

B

L

R

34

26

Figure 8

Bushings and Guage Wheel Arm

31700

36

36

28

26

36

28