Install new spindle, About bearing seals – Great Plains Gauge Wheel-Spindle User Manual

Page 8

Great Plains Mfg., Inc.

8

Dual Gauge Wheel/Spindle Update

195-080M

04/10/2009

Install New Spindle

About Bearing Seals

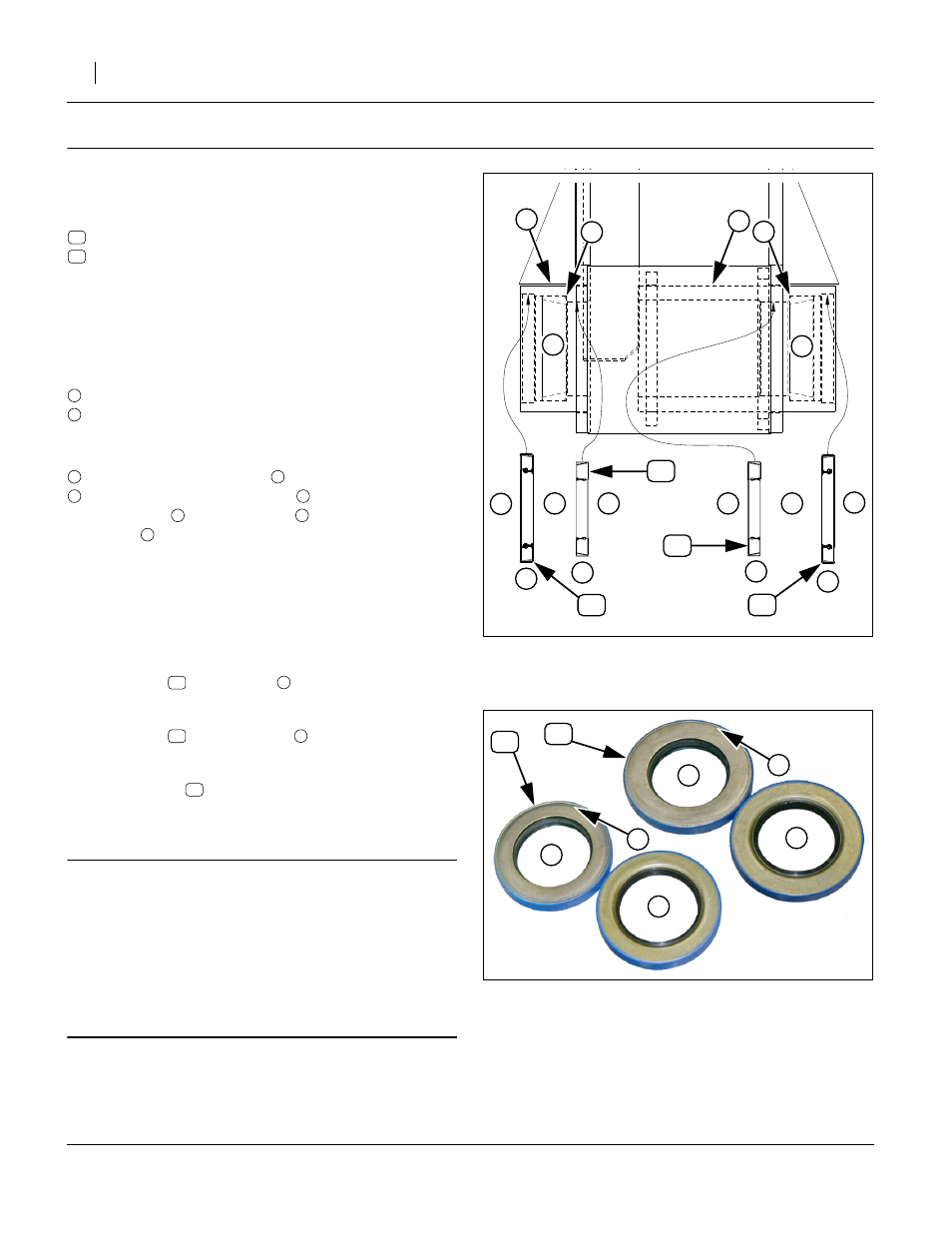

Refer to Figure 9 and Figure 10

The new bearing seals are supplied in two sizes:

816-012C SEAL 3.375 X 2.0 X.438 CR20125

816-138C SEAL DBL LIP 2.5 ID X 3.881 OD

The smaller diameter (inside) seals are installed into the

axle-cup weldments from the inside of the gauge wheel

weldment. The larger diameter (outside) seals are

installed from the outside.

Note that there are two different axle-cup weldments on

each gauge wheel:

a long hub, where the seal seats deeply, and

a short (shallow) hub.

These are reversed left-to-right on each side.

Bearing seals have distinct faces:

inner - toward sealed area

(bearing)

outer - away from sealed area

(bearing), and

The inner face

of the shells. The

outer face

has any printing on the housing. If the seal

has a visible taper at the outside diameter, the smaller

diameter side is the inside.

The seals and keyless hub must be installed in a specific

order, depending on the tools available. Using the sug-

gested tools, the order used in these instructions is:

a. bearing cups (if not left in place)

b. inside seal

in deep hub

c. keyless hub (not shown on this page)

d. inside seal

in shallow hub

e. bearing cones (not shown on this page)

f. outside seals

If using different tools, rehearse the sequence before

starting work.

IMPORTANT !

Seals are hollow metal structures and are somewhat

fragile. The are not intended to be in contact with the

bearings. When installing them, carefully align them

so they are concentric with the shaft hole. Apply

insertion force across the entire face, or at least

equally along the entire outside diameter (as close to

the shaft diameter as possible). See page 3 for tool

suggestions.

Figure 9

Seal Locations

29448

1

2

5

6

1

Figure 10

Bearing Seals

29447

6

4

3

2