Combination clutch/brake, Clutch/brake selection, Application data – Wichita Clutch CCB - Combination Clutch Brake Unit User Manual

Page 3: Selection

Combination Clutch/Brake

12

Wichita Clutch 800-964-3262

P-1100-WC 1/12

Clutch/Brake Selection

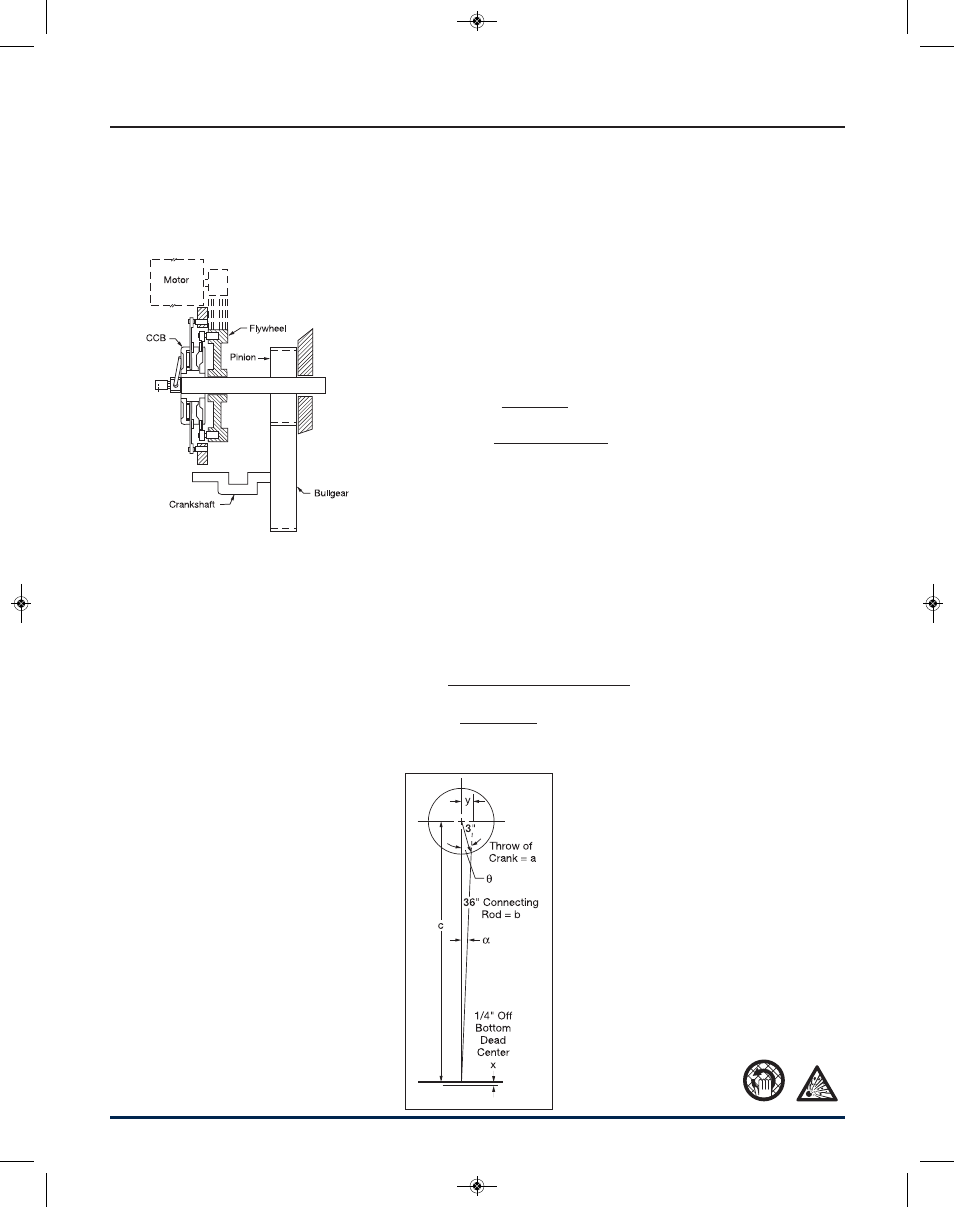

A typical Combination Clutch/Brake application

would be on a geared punch press. To properly

select a CCB the fol low ing application

information is needed.

1. To determine the proper Application Duty

Factor for a Geared Punch Press, consult

page 16. Under Duty “B” or Normal, the

Duty Factor is 1-1/2.

2. To determine the application clutch torque,

the following information is needed:

a. Torque @ Crank

= (Rated Tonnage) (2000 lb./ton) (Torque

Arm)

b. Torque Arm = y = (c) (tan a)

c = a + b - x

= 3 + 36 - .25

= 38.75 in.

b

2

+ c

2

- a

2

Cos

α

=

2bc

(36)

2

+ (38.75)

2

- (3)

2

=

(2) (36) (38.75)

= .99948

= 1.8478°

c. Torque Arm = y = (c) (tan

α

)

= (38.75) (tan 1.8478)

= (38.75) (.03226)

= 1.25 in.

Torque @ Crank

= (Rate Tonnage) (2000 lb./ton)(Torque Arm)

= (200) (2000) (1.25)

= 500,000 lb.in.

Required Torque @ Clutch

(Torque @ Crank) x (Crank shaft RPM)

=

lb.in.

Clutch Shaft RPM

(500,000) (30)

=

lb.in.

204

= 73,529 lb.in.

Application Data

Press Type . . . . . . . . . . . . Geared Punch Press

Rated Tonnage . . . . . . . . . . . . . . . . . . 200 tons

Crankshaft Speed . . . . . . . . . . . . . . . . 30 RPM

Degrees of Crank to Start . . . . . . . . . . . . . . 90°

Distance Above Bottom – x . . . . . . . . . . .25 in.

1/2 of Press Stroke (throw) = a . . . . . . . . . 3 in.

WR

2

of Parts on Backshaft . . . . . . . . . 78 lb.ft.

2

Required Clutch Torque. . . . . . . . . 73,529 lb.in.

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 in.

Clutch/Brake Shaft . . . . . . . . . . . . . . . 204 RPM

Degrees of Crank to Stop . . . . . . . . . . . . . . 120

Connecting rod length = b . . . . . . . . . . . . 36 in.

WR

2

of Parts on Crankshaft . . . . . 39,091 lb.ft.

2

Cycles/Minute . . . . . . . . . . . . . . . . . . . . . . . . . 7

Air Pressure Available. . . . . . . . . . . . . . 100 PSI

Shaft Size . . . . . . . . . . . . . . . . . . . . . . . . 4.5 in.

Selection

Press clutch and brake selection is

based on:

1. Application Duty Factor

2. Application clutch torque

3. Application brake torque necessary

to stop

4. Maximum Energy Input

5. Heat generated during cycling

6. Bore size

1/4" distance

above bottom

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 12