Installation instructions, Operation, Capacity – Powers SH1430 Hi/Lo Master Tempering Valves User Manual

Page 2

1. Installation should be in accordance with acceptable plumbing

practices. Flush all piping thoroughly before installation. Installation

and field adjustment are the responsibility of the installer.

2. Valves are to be installed as close to building inlet supply as

possible to prevent/minimize pressure fluctuations.

3. Valve body can be rotated to install in multiple positions due to

union inlets (see Figure 2). Make sure that union nuts are tightened

securely.

4. Connect inlets and outlet and check for leaks.

5. When the HydroGuard supplies tempered water to self-closing and/

or solenoid valves, provide a shock absorber (Powers Part No. 460-

353) on the discharge line.

6. Before use, check discharge temperature. Reset if

necessary.

OPERATION CHECK:

After HydroGuard is installed, make certain the supply stop valves and

strainers are free of debris, clean and ready for operation by disas-

sembling checkstops as shown in servicing.

Typical Flow

Hot and cold water supplies enter HydroGuard at indicated ports, (see

Figure 1) then flow past their respective seats. Next, hot and cold water

flow is directed to the mixing chamber where the thermostatic motor is

located.

Temperature Change

With a rise in discharge temperature due to pressure or temperature

fluctuation on the inlet, the actuator expands, decreasing flow of hot

water. The reverse occurs with a drop in discharge temperature.

Responses

Temperature adjustment screw moves the actuator to the desired

discharge temperature.

• Cold water supply failure – causes actuator to expand drastically

reducing the flow of hot water

*

.

• Hot water supply pressure failure – causes actuator to contract

drastically reducing the flow of cold water

*

.

*

When tested in accordance to conditions described in ASSE 1017.

Installation Instructions

n

Operation

n

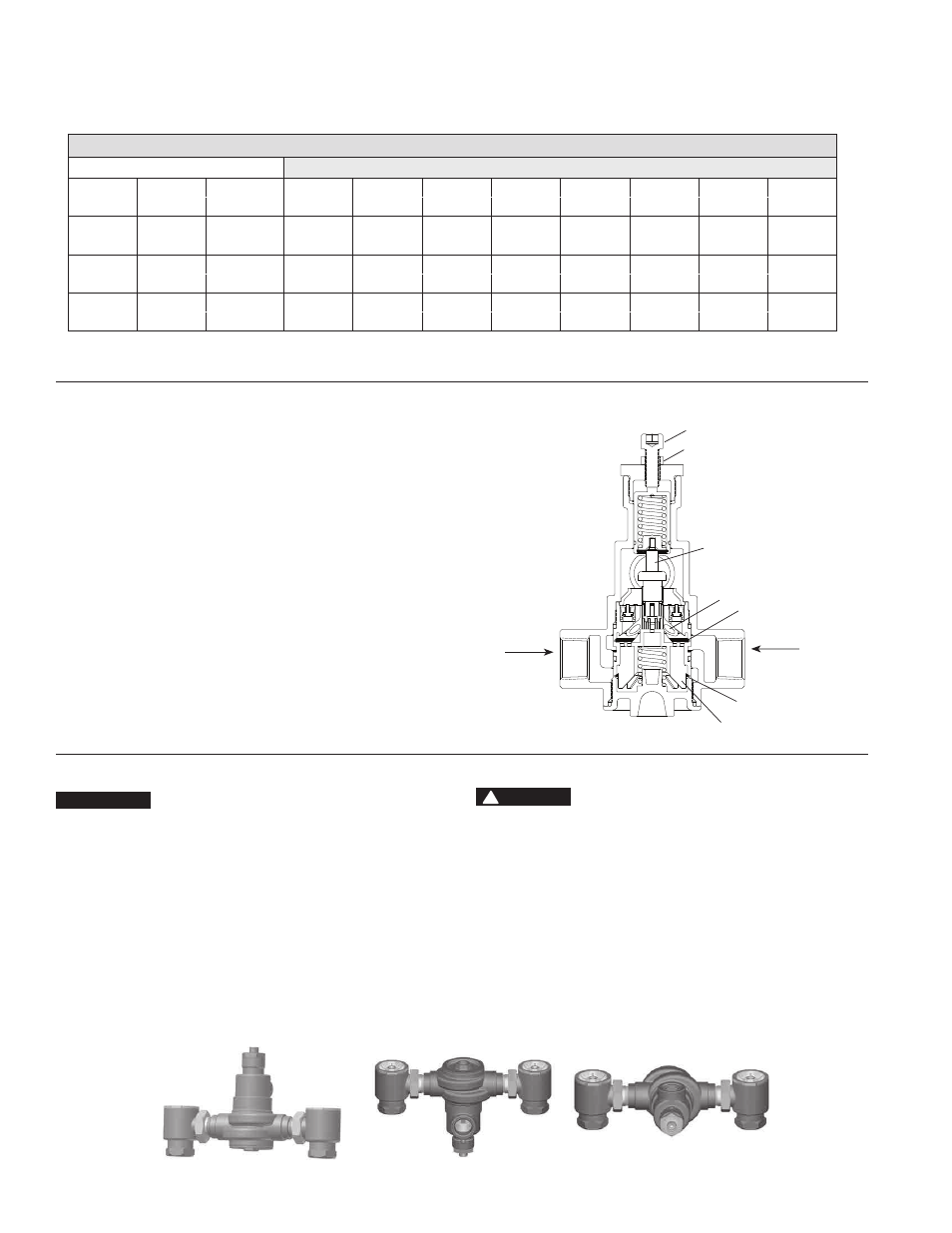

Figure 2

Back Outlet

Front Outlet

Top Outlet

2

Figure 1

Temperature Adjustment Screw

Temperature Adjustment Locknut

Actuator

Mixing Chamber

Cold Water Seat

Hot Water

Seat

Cold Water

Hot Water

Plunger

Flow Capacity at 50-50 mixed ratio

P r e s s u r e D r o p A c r o s s V a l v e

Model

Min. Flow

Min. Flow

C

V

5psi

10psi

20psi

30psi

45psi

60psi

70psi

Rate*

to ASSE 1017

(34 kPa)

(69 kPa)

(138 kPa)

(207 kPa)

(310 kPa)

(414 kPa)

(517 kPa)

LFSH1432

0.5 gpm

1 gpm

8.54

19 gpm

27 gpm

38 gpm

47 gpm

57 gpm

66 gpm

71 gpm

1.89 lpm

4 lpm

72 lpm

102 lpm

144 lpm

178 lpm

216 lpm

250 lpm

269 lpm

LFSH1434

0.5 gpm

1 gpm

19.00

42 gpm

60 gpm

85 gpm

104 gpm

127 gpm

147 gpm 159 gpm

1.89 lpm

4 lpm

159 lpm

227 lpm

322 lpm

394 lpm

481 lpm

556 lpm

602 lpm

LFSH1435

0.5 gpm

5 gpm

30.00

67 gpm

95 gpm

134 gpm

164 gpm

201 gpm

232 gpm 251 gpm

1.89 lpm

19 lpm

254 lpm

360 lpm

507 lpm

621 lpm

761 lpm

878 lpm

950 lpm

* Minimum flow when HydroGuard is installed at or near hot water source with recirculated tempered water with continuously operating recirculating pump.

Capacity Table, presents the HydroGuard discharge capacity in gpm

and lpm for various pressure drops across the valves (the difference

Capacity

n

between the lowest inlet pressure and the discharge pressure at the

HydroGuard.)

CAUTION

!

NOTICE