HF scientific MicroTUV Online UV %Transmission Sensor/Sampler (small) User Manual

Page 11

2.3.

2.3.

2.3.

2.3.

2.3.2

2

2

2

2

Removing and Installing the Desiccant Tray

Removing and Installing the Desiccant Tray

Removing and Installing the Desiccant Tray

Removing and Installing the Desiccant Tray

Removing and Installing the Desiccant Tray

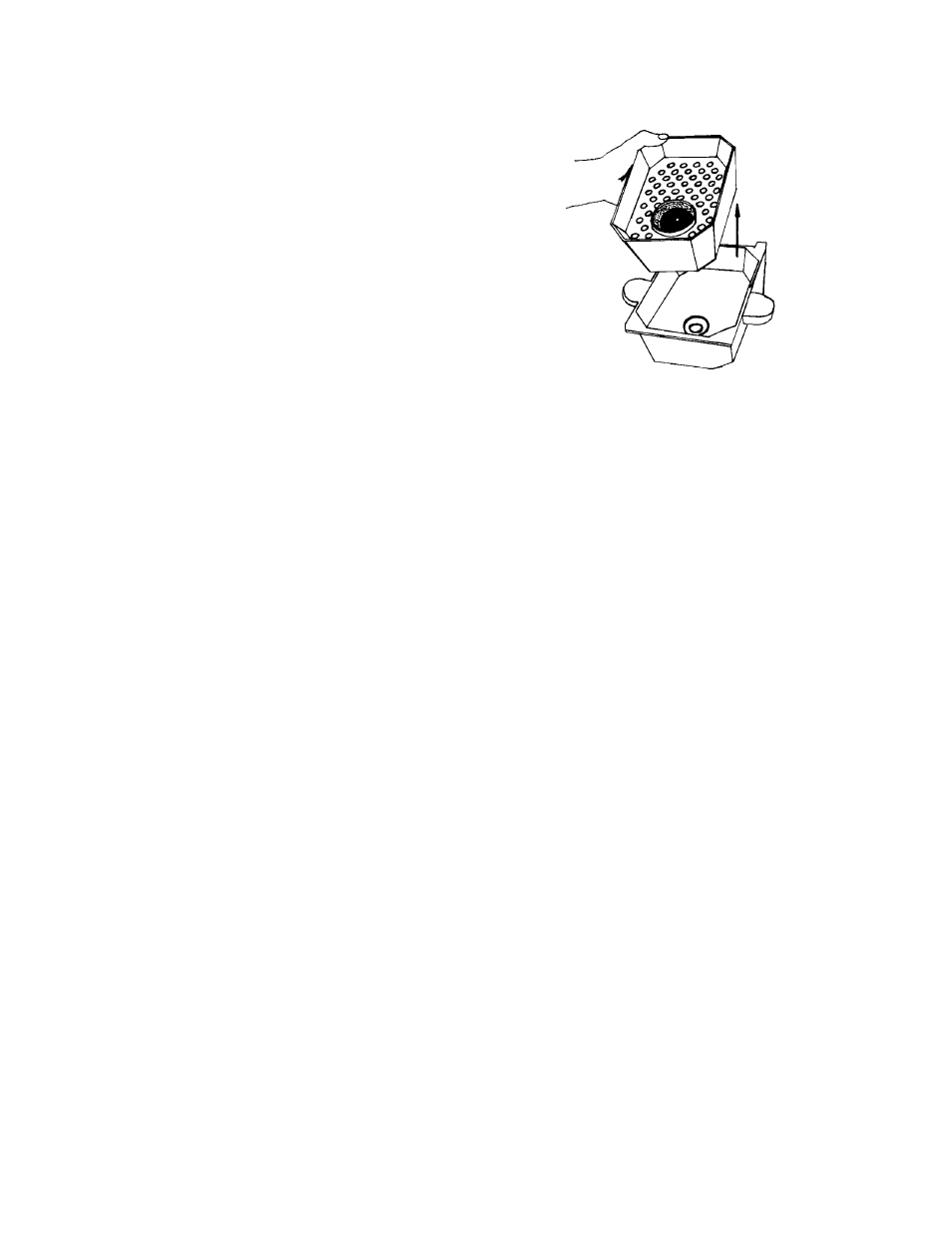

Before operating the unit for the first time, the desiccant tray,

foot valve and O-rings must be installed in the sensor housing.

These items are shipped in a moisture resistant pouch. Use care

when opening so as not to damage the contents. The smaller O-

ring #205 goes into the desiccant tray, at the foot valve seat. O-

ring #218 goes underneath the desiccant tray in the O-ring

groove provided in the housing. Refer to figure 1 for details. See

section 6.4 for maintenance instructions.

2.3.

2.3.

2.3.

2.3.

2.3.3

3

3

3

3

Sensor/Sampler Plumbing

Sensor/Sampler Plumbing

Sensor/Sampler Plumbing

Sensor/Sampler Plumbing

Sensor/Sampler Plumbing

There are two external connections required. The first is the source line with the strainer at its foot. The second

is the drain line. These hoses are shipped in separate plastic bags in the Sensor/Sampler enclosure. The source

and drain lines should not exceed 25 feet (7.6 m) in length. The flow rate may be substantially reduced if the

lines are extended any further. The sampling flow rate is 140 ml/min. - 180 ml/min.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Only route drain line to a free flowing drain.

Only route drain line to a free flowing drain.

Only route drain line to a free flowing drain.

Only route drain line to a free flowing drain.

Only route drain line to a free flowing drain.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Only use as much line as needed. The excess should be cut off.

Only use as much line as needed. The excess should be cut off.

Only use as much line as needed. The excess should be cut off.

Only use as much line as needed. The excess should be cut off.

Only use as much line as needed. The excess should be cut off.

If any of the above conditions are not met, a flow error or an emergency drainage may occur.

2.4

2.4

2.4

2.4

2.4

COLD WEATHER

COLD WEATHER

COLD WEATHER

COLD WEATHER

COLD WEATHER KIT

KIT

KIT

KIT

KIT INSTALLATION

INSTALLATION

INSTALLATION

INSTALLATION

INSTALLATION

2.

2.

2.

2.

2.4.1

4.1

4.1

4.1

4.1

Heating Cable Installation

Heating Cable Installation

Heating Cable Installation

Heating Cable Installation

Heating Cable Installation

Disconnect power before installing the heating cable. The drain and intake lines must be sized to the proper

length before installing the heating cable. First, measure the amount of heating cable necessary to run from the

heating cable bulkhead on the bottom of the Sensor/Sampler enclosure to 2 inches above the maximum level of

the effluent stream and add 9 inches (230 mm) for the connections inside. If the heating cable needs to be cut

to length, make the cut at the open end, not the yellow sealed end. Next, prepare the cut end for connections

(see Figure 6). After the cable is prepared, unscrew the compression nut on the heating cable bulkhead on the

bottom of the instrument enclosure located between the intake and drain bulkheads (see Figure 7). Remove the

slotted through plug, it will be used later. Replace the compression nut, but do not tighten. Remove the cover of

the vertical wiring duct by pressing the fingers on the sides inward. Locate the heating cable power block (labeled

L3 & L4). The heating cable should now be stripped and prepared for power and ground connection at one end,

and sealed at the other. Feed the prepared end carefully through the bulkhead far enough to make the power and

ground hookup (about nine inches). Connect the power wires to the power block and the rolled braided shield wire

to the ground terminal block (see Figure 4). Run the heating cable into the wiring duct and through the fingers so

there are no kinks or slack in the cable. Replace the wiring duct cover. Unscrew the compression nut and allow

it to slide down the cable a few inches. The slotted through plug should be slit on one side to allow it to be wrapped

around the heating cable. Wrap it around the cable with the chamfered end down just below the bulkhead fitting.

Slide the plug into the bulkhead and tighten the compression nut behind it by hand. A wrench should not be

necessary.

Refer to Figures 4, 6 and 7.

TUV (01/03)

Page 3

REV. 2.2

Figure 1

Desiccant Tray Installation

WARNING:

WARNING:

WARNING:

WARNING:

WARNING:

If the power connection is to be hardwired, place

If the power connection is to be hardwired, place

If the power connection is to be hardwired, place

If the power connection is to be hardwired, place

If the power connection is to be hardwired, place TUV

TUV

TUV

TUV

TUV on a separate circuit breaker or

on a separate circuit breaker or

on a separate circuit breaker or

on a separate circuit breaker or

on a separate circuit breaker or

switch to allow for service. Observe all local wiring codes. Site connections should be wired by a Qualified

switch to allow for service. Observe all local wiring codes. Site connections should be wired by a Qualified

switch to allow for service. Observe all local wiring codes. Site connections should be wired by a Qualified

switch to allow for service. Observe all local wiring codes. Site connections should be wired by a Qualified

switch to allow for service. Observe all local wiring codes. Site connections should be wired by a Qualified

Electrician.

Electrician.

Electrician.

Electrician.

Electrician.