Aerovent IM-105 User Manual

Shutter types and construction, Im-105, Typical shutter installations

©1997 Aerovent

Automatic

Automatic shutters are constructed with galvanized steel

frames and drilled for ease of installation. Aluminum felt-

edged blades open from fan pressure and close automatically

when fan is off. All aluminum construction is available as an

option.

Motor-Operated, End-Pivoted

Used for exhaust only. Constructed of galvanized steel frames

and aluminum felt-edged blades. Flanges are drilled for ease of

installation. Motor-operated units are furnished with electric

actuators. These actuators are not equipped with end switches.

All-aluminum construction is available as an option.

Motor-Operated, Center-Pivoted

Can be used in either supply or exhaust applications.

Constructed of galvanized steel frames and blades with stain-

less steel jamb seals. Blades are held in place with oil-impreg-

nated bronze bushings. Motor-operated units are supplied

with electric actuators that are furnished with end switches.

Shutter Types and Construction

Typical Shutter Installations

Manually-

Operated

Manually-operated

shutters are of the

same rugged construc-

tion as the automatic

shutter. This shutter is

supplied with a six-foot

pull chain connected

through a pulley on the

inside of the shutter.

Spring arrangement

holds louver tightly

closed when unit is not

in use. All aluminum

construction is avail-

able as an option.

Extra Heavy-Duty

Extra heavy-duty shutters are recommended where discharge

velocity exceeds 2400 FPM or where velocity is low and exces-

sive fluttering action is a concern. All extra heavy-duty shutters

have 16-gauge aluminum blades. Can be provided as auto-

matic, manual or motorized operation.

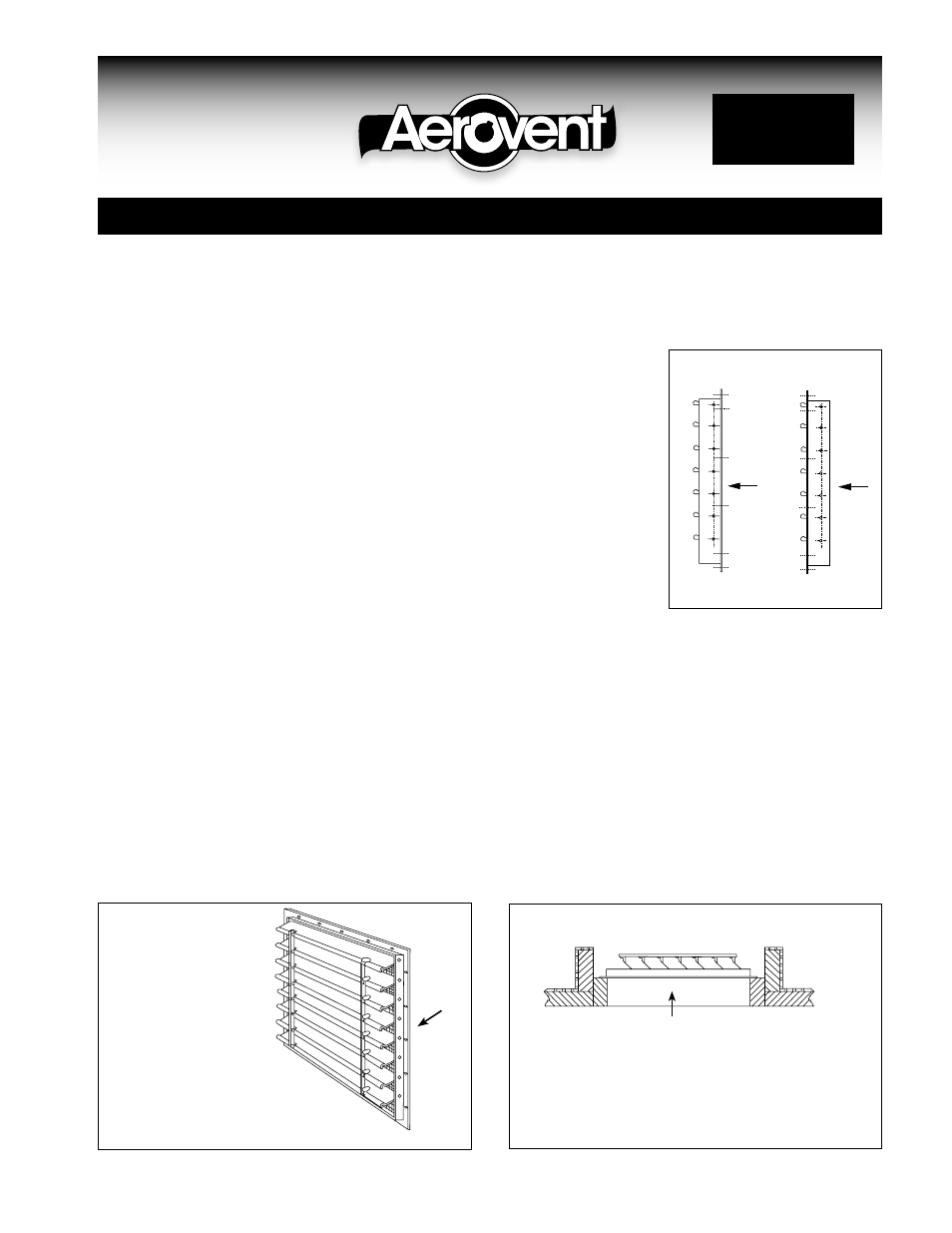

AIRFLOW

AIRFLOW

STANDARD

FLANGE

REVERSE

FLANGE

AEROVENT SHUTTER

FLANGE ARRANGEMENT

AUTOMATIC TYPE:

Designed for horizontal

airflow — gravity close.

Optional bird screen

shown.

Airflow

CEILING TYPE: Designed for vertical airflow.

Auto-matic gravity close. Exhaust only

Airflow

General Installation, Operation and Maintenance Instructions For Aerovent Products

IM-105

June 1997

®