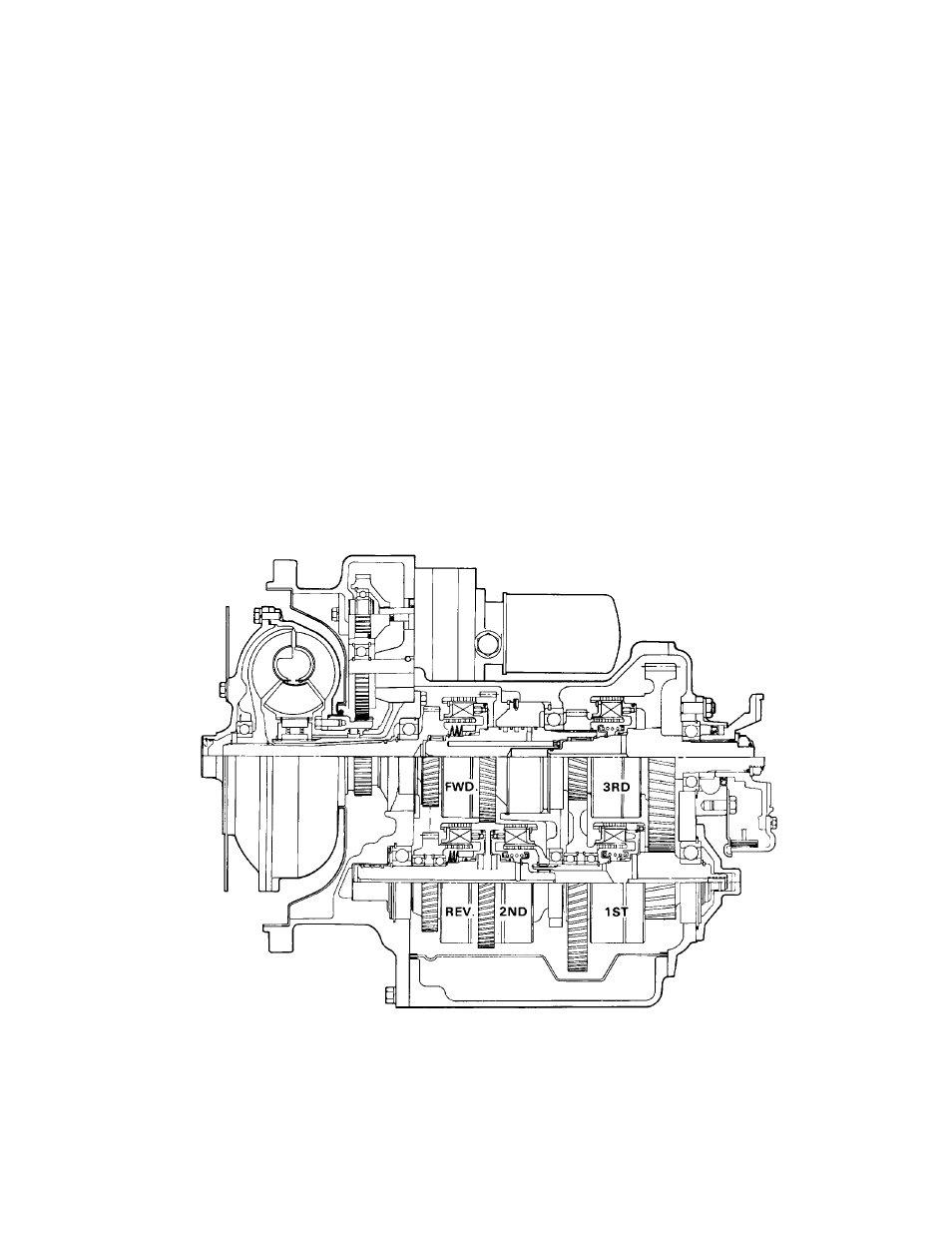

Sectional views and parts identification, Basic design – Gradall 534B (9020-7317) Service Manual User Manual

Page 146

When either directional clutch is selected the opposite clutch is relieved of pressure and vents back through

the direction selector spool. The same procedure is used in the speed selector.

The direction or speed clutch assembly consists of a drum with internal splines and a bore to recieve a hy-

draulically actuated piston . The piston is “oil tight” by the use of sealing rings. A steel disc with external

splines is inserted into the drum and rests against the piston. Next , a friction disc with splines at the inner

diameter is inserted. Discs are alternated until the required total is achieved . A heavy back-up plate is then

inserted and secured with a snap ring. A Hub with O.D. splines is inserted into the splines of discs with

teeth on the inner diameter The discs and hub are free to increase is speed or rotate in the opposite direc-

tion as long as no pressure is present in that specific clutch.

To engage the clutch, as previously stated , the control valve is placed in the desired position. This allows

oil under pressure to flow from the control valve , through a passageway, to a chosen clutcth shaft. This shaft

has a drilled passageway for oil under pressure to enter the shaft. Oil pressure sealing rings are located on

the clutch shaft. These rings direct oil under pressure to a desired clutch. Pressure of the oil forces the piston

and discs against the heavy back-up plate. The discs, with teeth on the outer diameter clamping against

discs with teeth on the inner diameter , enables the hub and clutch shaft to be locked together and allows

them to drive as a unit.

There are balls or bleed orifices, depending upon the model, in the clutch piston which allow quick

e s c a p e f o r o i l w h e n t h e p r e s s u r e t o t h e p i s t o n i s r e l e a s e d .

BASIC DESIGN

Figure A