InnoMax Softside Fluid User Manual

Page 3

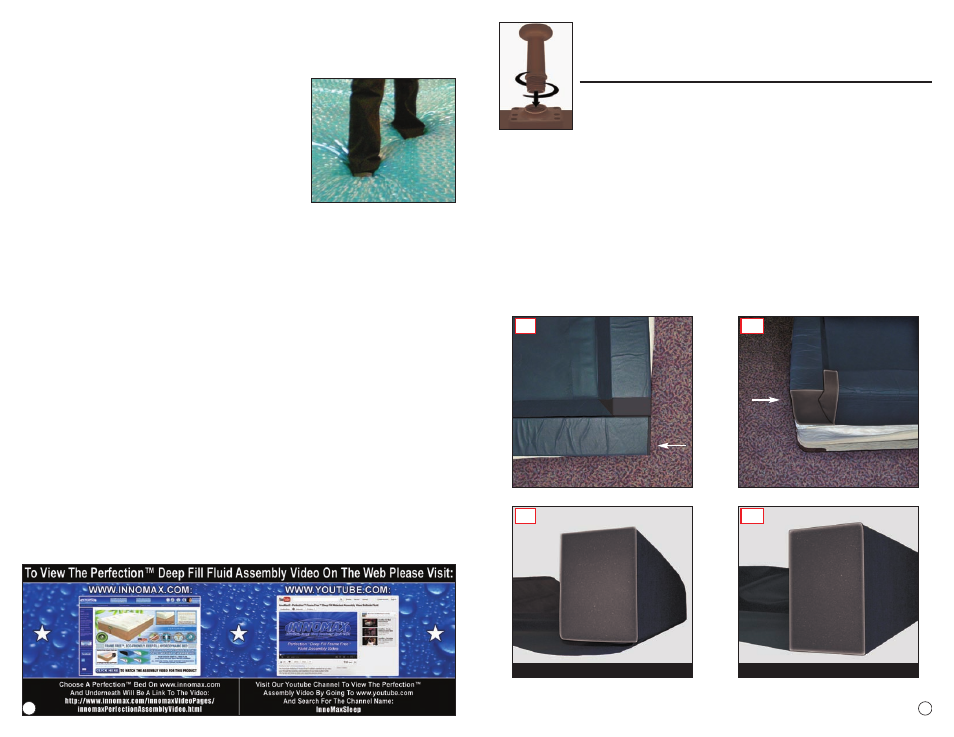

3. Unfold the mattress enclosure and completely unzip the cover.

Insert the

head and foot rail inside the cover. The head of the bed should be stamped and

will have two slits in the black webbing material.This is for the exit of your temperature

control sensor and heater pad power cord. The side rails are inserted in between

the head and foot rails with the webbing as smooth as possible. The rails are

correctly installed when the webbing material is completely unrolled and is at the

bottom of the rail (see DIAGRAM

B2

). The rail should be approximately 6” in

height and 4” in width.

Exception:

The Perfections

®

Sponge Bed

™

is a full depth

flotation style system and is designed with the “M Rail System” which is

approximately 8” in depth and has interlocking slanted rails (see DIAGRAM

A2

).

The black webbing is also to be at the bottom of the rail (see DIAGRAM

B2

).

legs rest upon the ground and you have the firm, flat side of the

foundation is facing up. You are now ready to begin the bed

assembly.

For the assembly video of this product please visit:

www.innomax.com

or

www.youtube.com

under the channel name

InnoMaxSleep

2

5

B1

INCORRECT

Black Webbing Running Under Rails

B2

CORRECT

Black Webbing Running Straight Out

From Rails

A1

Perfection Rails Top View

Foot

Of Bed

A2

Perfection Rails Side View

Foot

Of Bed

4. Install the heater pad(s) directly on the black webbing material in head to

toe position.

Ensure that the entire pad is on a solid (CONTINUED)

all of the trapped air. Use the Air Extractor to remove the excess air.

10. Several of InnoMax’s

®

firmer water chambers feature a high level of fiber,

closed cell and/or sponge support sheets.

These layers need to become fully

saturated with water to provide the desired comfort

levels. This process may take several days and may

require you to walk or roll on the mattress many times

during this period to extract as much air as possible.

While this early portion of the mattresses life may be

somewhat inconvenient, you will off set the extra

effort with the enhanced comfort you will enjoy for

years to come. The mattress may not feel as it did in

the showroom until you have finished this process. It

is recommended that you do not adjust fill levels to change firmness levels during

this process. Most sleepers find that following the “break end” period, the initial fill

level is the preferred setting.

11. Plug the heater pad into the heater control.

Plug the control into a 110 volt

wall outlet and then set the temperature to the desired level. It is recommended to

be set between 80-87 degrees Fahrenheit depending upon your personal comfort

level. If you have a dual heating system, repeat this step for the other side of the

mattress.

12. Zip up the cover/pillow top.

Install the new mattress pad and sheets. Enjoy

a great night’s sleep on your new fluid support system!

13. Maintenance of your fluid support sleep system.

To receive the maximum

comfort, enjoyment and longevity from your new fluid system, it is important to

perform periodic maintenance. In addition to the use of quality waterbed conditioner

on an annual basis, it is recommended to use Blue Magic

®

Vinyl Cleaner on the outside

of your water chamber(s) and vinyl safety liner at least 2-3 times per year to

prevent plasticizer migration which dries vinyl and can cause brittleness, and in

some cases, cracking of the surface. Also, vinyl is a porous surface and over time,

air molecules can pass through into the chamber requiring the use of the Air

Extractor to remove the trapped air bubbles. This small amount of maintenance

will allow you to benefit from the amazing comfort and support of your fluid

system for many years to come.