Instruction, Manual ni-491e – WIKA TCA User Manual

Page 4

INSTRUCTION

MANUAL

NI-491E

Rev. 5 11/02

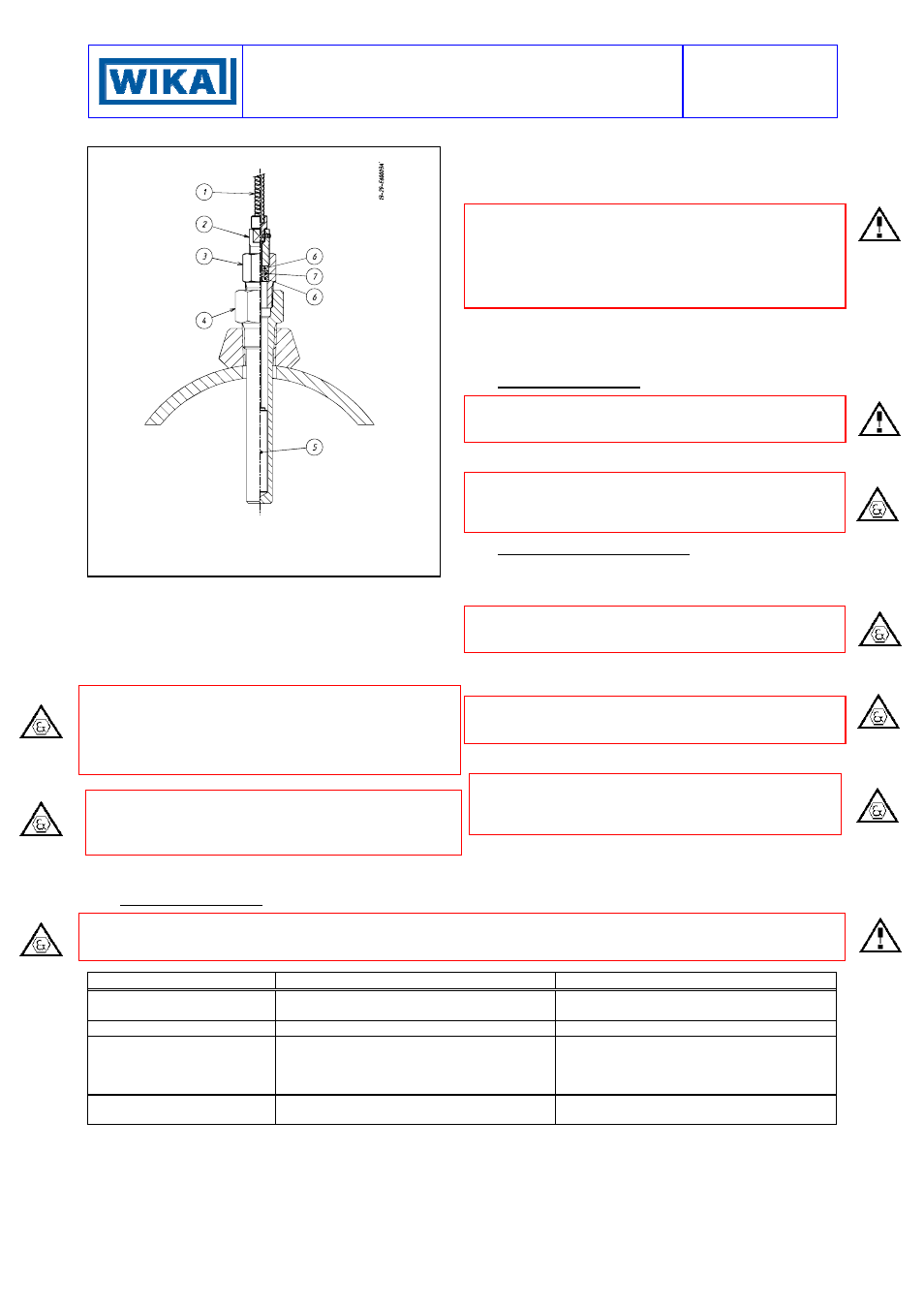

Fig. 5 -

Mounting the bulb

1) Armored

capillary

2) Stuffing nut (SW 12)

3) Rotating fitting (SW 22)

4) Thermowell

5) Bulb

6) Stainless steel washer

7) PTFE

washer

Extend the capillary protected by the sheath in the established

direction, avoiding tight bends, and block using the stainless steel

bands.

If a large amount of capillary remains this should be rolled up and

fixed tightly. The coil must not have a diameter of less than 200

mm.

7.3 ELECTRICAL CONNECTIONS

It is recommended to carry out the electrical connections accord-

ing to the applicable standards. In case of explosionproof instru-

ments (Series TCA) see also the Standard EN-60079-14. If the

electrical connection is carried out in a protected tube, it shall be

made so that condensate is prevented from entering instrument

enclosure.

The arrangement shown in Fig. 6 or 7 is therefore recommended.

CAUTION:

fittings used for the electrical connection of the

pressure switch Series TCA (explosionproof) shall be certified to

Standards EN 50014 and 50018, and shall guarantee instrument

degree of protection (IP65).

Check that there is no power in the lines.

Remove the cover and carry out the cabling and connections to

the terminal block (see Fig. 2).

Flexible cables with a maximum section of 1.2 mm

2

(16AWG) are

recommended using the pre-insulated test prod thimbles with a

maximum diameter of 2.5 mm supplied with the instrument.

When inserting cables into the enclosure pay attention not to

force the microawitch with cable or tools, otherwise instrument

calibration or even its operation could be compromised. The

microswitch has been factory mounted and positioned in order to

obtain the best performances. Any tampering made on site with-

out following instructions authorised by the E. CELLA SPA may

result in instrument malfunction.

Ensure that no deposits or wire ends remain inside the case.

Once the connection operations have been completed, replace

the cover and ensure that it is properly sealed and blocked. See

Fig. 3.

8 - MESSA IN FUNZIONE

As the signal transmitted by the instrument is used in a complex

system, it is necessary that the means of putting it into operation

are established by personnel in charge of the plant

.

The instrument starts working as soon as it is connected to an

electrical line.

In case of explosionproof instruments (Series TCA), initial

inspections are to be carried out according to customer

procedures and at least in accordance with Standard EN-60079-

17.

9 - FUNCTIONAL VERIFICATION

Si effettuerà secondo le modalità previste dal piano di controllo

del Cliente. Series TCS instruments can be verified on the plant if

mounting is done as illustrated in Fig. 6 and 7.

The instruments Series TCA may be checked on site only if

apparatus suitable for explosive atmosphere are used and

provided that the electric line is not energized.

If this is not the case it is necessary to stop operation, dismount

by means of the three piece joints and carry out the verification in

a test room.

CAUTION: do not open the cover of explosionproof temperature

switches (Series TCA) when energized, in explosive atmos-

pheres.

Verification consists in checking the calibration value and

possibly regulatory the adjustment bush (see §5).

In case of explosionproof instruments (Series TCA), inspections

of the electrical installation are to be carried out also according to

customer procedures and at least in accordance with Standard

EN-60079-17.

10 - TROUBLESHOOTING

IMPORTANT NOTE: operations involving replacement of essential components must be carried out at our workshop, especially

for instruments with explosionproof certificate; this is to guarantee the user the total and correct restoration of the product

original characteristics.

MALFUNCTION PROBABLE

CAUSE

REMEDY

Set point shift

Deposits on thermowell or bulb.

Filling fluid leakage.

Check and clean surfaces.

Replace the instrument.

Slow response

Deposits on thermowell or bulb.

Check and clean surfaces.

No actuation

Loosened electrical joints.

Interrupted or short-circuited electrical line.

Microswitch contacts damaged.

Filling fluid leakage.

Check all electrical joints.

Check the conditions of the electrical line.

Replace the instrument.

Replace the instrument.

Undue actuation

Accidental shocks.

Interrupted or short-circuited electrical line.

Modify the mounting.

Check the conditions of the electrical line.