C. electrical wiring, Separate circulator – Amtrol TD-7ZDW User Manual

Page 8

-8-

Step 5 - Connect boiler supply pipe. Figure 1.

a. Shut off the cold water supply valve to the boiler, and

drain it using a hose attached to the drain valve at the

boiler.

b. When the boiler system piping is drained, cut the

piping to accommodate the supply line tee. Install the

tee between the boiler supply outlet and any system

zone valve or flow check.

c. Connect the circulator flange and mount the

circulator to the boiler supply. Be sure the flow

arrow points towards the BOILER MATE™

. Mount

the second flange to the circulator.

d. Connect a 3/4" NPTM to a 3/4" sweat adapter to the

second circulator flange.

e. Using short lengths of tubing, connect the 3/4"shut-

off valve.

f. Run the 3/4"copper tubing with necessary fittings to

the point of connection to the boiler supply tee.

Step 6 - Connect boiler return pipe. Figure 1.

a. Connect the 3/4" NPT, boiler return fitting and

connect the drain valve and union.

b. Sweat a short length of tubing to the adapter and

connect the weighted check valve with the flow

towards the boiler (preventing flow towards the

BOILER MATE™). Failure to do so will result in the

BOILER MATE™ overheating.

c. Run the 3/4" tubing and fittings as required to the

point of connection to the boiler return.

NOTE: This point must be between the boiler return

tapping and any system circulator(s). Failure to do so

will result in the BOILER MATE™ overheating.

Step 7 - Refill the boiler system

a. Open the cold water supply valve to the boiler.

b. Check for system leaks.

c. Close the weighted check valve on the boiler return

piping of the BOILER MATE™

d. Open the drain valve on the boiler return line to

release entrapped system air.

e. Close the drain valve

f. Open the weighted check valve.

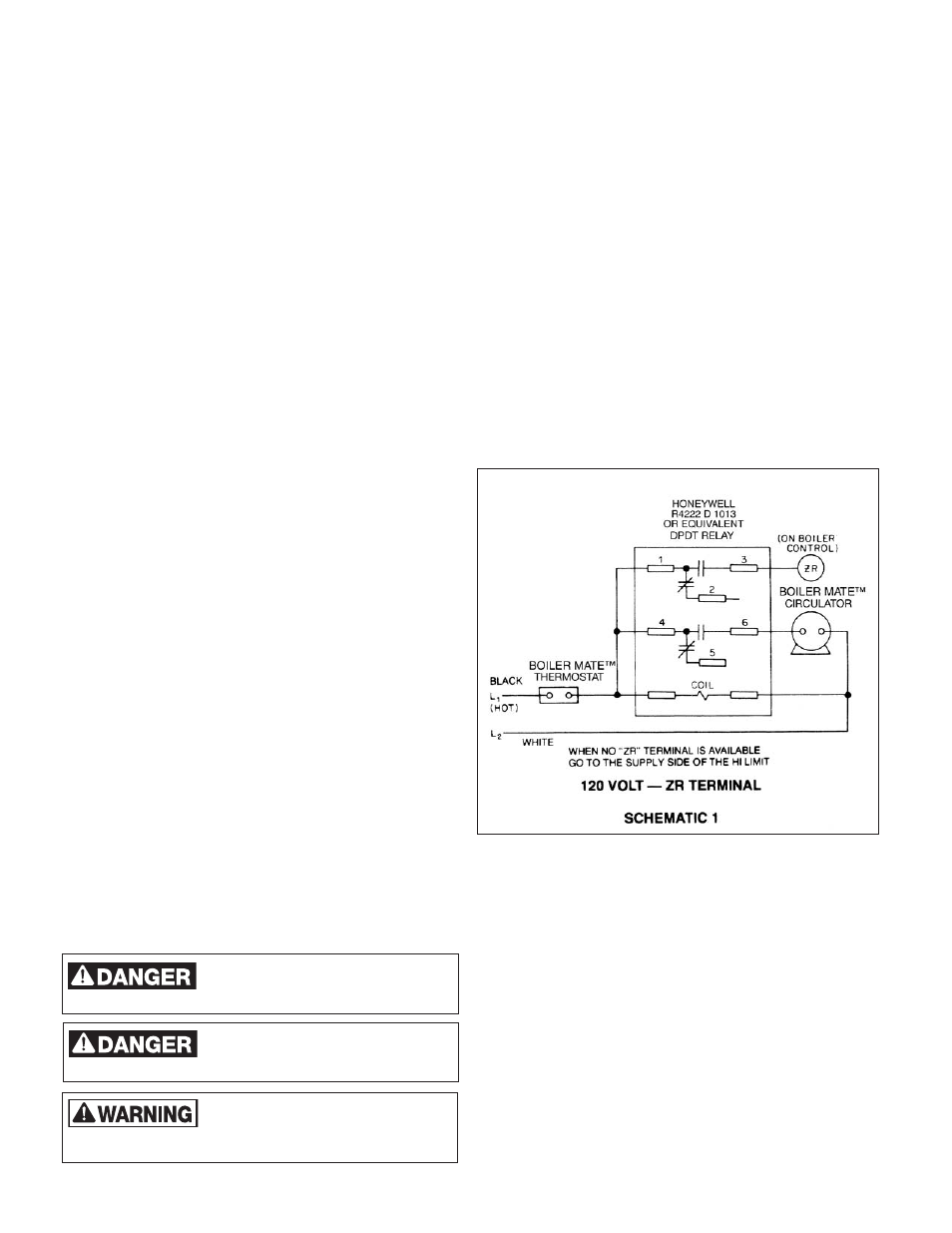

C. ELECTRICAL WIRING

All wiring must be in accordance with local codes, regulations,

and ordinances or, in the absence of such codes, the National

Electrical Code ANSI/NFPA No. 70, latest edition.

The BOILER MATE™ thermostat can be used for either 24 or

120V AC. The thermostat is packaged separately and is installed

by sliding the capillary tube into the thermostat well.

Electrocution hazard. First

dis-connect

all electrical power

before doing any electrical work.

Electrocution hazard. The BOILER

MATE™ must be electrically

grounded.

Electrical supply must come from the

boiler side of boiler’s emergency

shut-off switch in order to prevent

unsafe boiler operation.

SEPARATE CIRCULATOR

I. BOILER MATE™ as Separate Zone - Non-Priority

A. Use of separate BOILER MATE™ ZONE CIRCULATOR

Step 1 - Disconnect electrical power.

a. Turn off the boiler service switch.

b. Turn off the safety switch (if separate from

the service switch).

c. Switch off the branch circuit breaker.

Step 2 - Remove electrical box cover on Thermostat.

Step 3 - Wire BOILER MATE™ using

Schematic #1 or #2.

a. Install BX connector.

b. Insert outside wiring to BOILER MATE™

through electrical conduit opening on

thermostat.

c. Complete exterior electrical wiring per

Schematic #1 or #2.

Step 4 - Turn boiler low-limit control (it is part of the

boiler control) to the off position.

Note: Some boilers require minimum setting of low limit.

Step 5 - Adjust boiler high-limit control to the desired

setting. In most cases 180° F to 200° F

is acceptable.

Step 6 - Re-assemble electrical box cover.

Step 7 - Re-connect electrical power.

B.

Use of only the heating system circulator.

When wiring a separate zone valve, follow all steps in 1A

except for Step 3c. Use Schematic #3(A, B or C)

depending upon the type of zone valve. (Zone valve

sizing per pg. 5)

II. BOILER MATE™ - Priority Wiring

Hot Water Before Space Heating

A. Use of separate BOILER MATE™ zone.

A DPDT relay is to be used. Refer to Schematic #4.

Step 1 - Disconnect electrical power.

a. Turn off the boiler service switch.

b. Turn off the safety switch (if separate from

SEPARATE CIRCULATOR