Pulsafeeder PULSAtron Series ET User Manual

Page 11

10

5.5 Operation By External Input Signals (Options):

The pump can be controlled by three types of input signals. All are fully isolated from AC input and from earth ground.

The input socket connections are located at the bottom of the control panel face and the signal cords are provided with

the pump. Remove rubber plugs to access plug sockets.

5.5.1 Stop Function (E+, A+, C+, C and HV only)

Operation of the pump can be stopped by an external signal input. When the external signal is input to the terminal

marked which is provided at the bottom of the control panel, the lamp (red) lights up and operation of the pump is

stopped. The stop function overrides both manual settings and external input.

Operation of more than one pump from the same contact closure will damage the pump circuits.

When such operation is required, the pump circuits must be electrically isolated from one another by means of a

multi-contact control relay or similar means.

The input signal must be in the form of closure of a mechanical relay or other mechanical switching device, or solid-state

relay or other solid-state switching device. Voltage signals are prohibited. The switching resistance of either mechanical

or solid-state devices must be 100 ohms or below when ON and 1 megohm or above when OFF. If any type of solid-state

device is employed, it must be installed with the proper polarity, if required for the device; and leakage current must not

exceed 200 microamperes to prevent false triggering in the OFF state.

The stop function is commonly used in conjunction with a tank float switch. The float switch contacts are normally open

but when the tank level falls past a certain point the contacts close and the pump stops.

5.5.2 External Pacing Function (E+, A+, C+, C and HV only)

The pump's stroke rate can be controlled by an external signal input. When the input signal line is connected and the

EXTERNAL /OFF /MANUAL switch is in the external position and a contact signal is input to the terminal marked

, the

pump makes one discharge stroke.

Operation of more than one pump from the same contact closure will damage the pump circuits.

When such operation is required, the pump circuits must be electrically isolated from one another by means of a

multi-contact control relay or similar means.

When the “ON” signal pulse is input, the pump operates one stroke and the fluid is discharged. In addition, the pump can

be operated continuously to its maximum strokes/min. by repeated

input of “ON” and “OFF” signals.

After receiving an input signal, the pump generates the necessary power pulse to actuate the solenoid. The external

signal input is debounced by the pump circuit. The pump will not stroke in response to a spurious or erratic input signal

that follows at a rate greater than its maximum strokes/minute. If the external signal rate exceeds its maximum

stokes/minute, the pump will stroke at half the external signal rate to prevent overdosing and to protect the pump from

overheating.

The input signal must be in the form of closure of a mechanical relay, other mechanical switching device, or of a solid-

state switching device. Voltage signals are prohibited. The switching resistance of either mechanical or solid-state

devices must be 100 ohms or below when ON and 1 megohm or above when OFF. If any type of solid-state device is

employed, it must be installed with proper polarity, if required for the device; and leakage current must not exceed 200

microamperes to prevent false triggering in the OFF state.

Cycle rate of the input signal should not exceed the maximum stroke/minute speed of the pump.

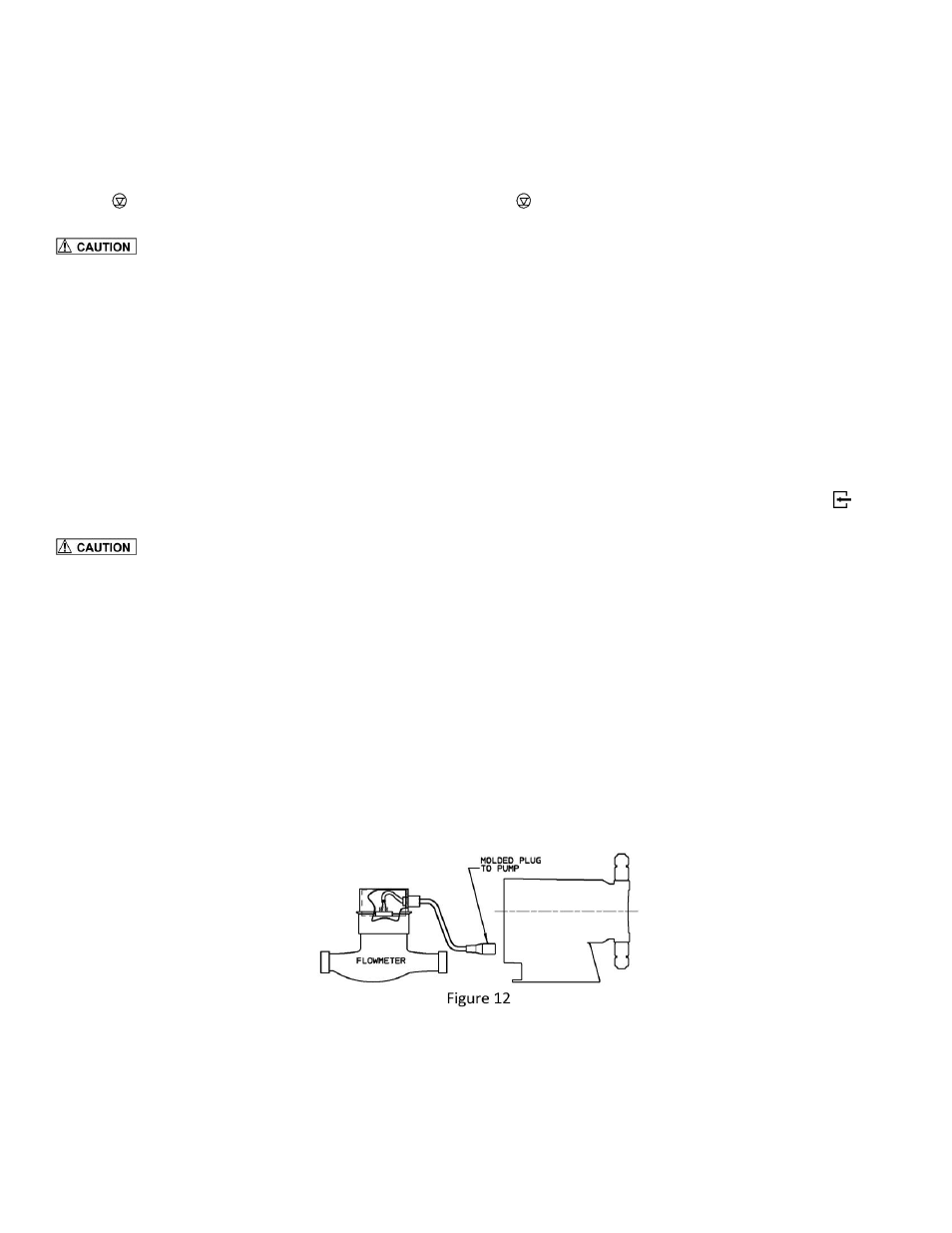

Typical wiring is shown at right for use with switch closure flow-meters. (Figure 12)

10 millisecond contact time required for each “ON” input signal.

5.5.3 4-20mA DC Input Function (E+ and HV only)

The pump’s stroke rate can also be controlled by a 4-20 mA DC signal to the terminal marked [4-20 mA].