Actron CP8201 User Manual

Water/oil temperature gauge instructions, Installation, Precautions

1

WATER/OIL TEMPERATURE GAUGE

INSTRUCTIONS

Warning: If your car is microprocessor (computer) controlled or has an electric cooling fan, refer to

the section on the front cover titled Microprocessor Controlled Engines.

6. Never install the captive fitting on the capil-

lary tube directly into the engine without an

adapter, as a proper seal will not be formed.

INSTALLATION

Note: If you are planning to use both an oil

temperature gauge and an an oil pressure

gauge, some modifications may be

necessary as there is only one available hole

for both senders. Since the temperature

gauge cannot use a T-fitting, we suggest that

you install the oil temperature sender into

the oil pressure warning light sender location

in the engine block. Then obtain an adapter

(which we do not manufacture) used for oil

coolers which will give you an additional outlet

for oil pressure.

FOR MECHANICAL GAUGES:

1. Drain the fluid level in the system to below the

senders mounting location which is normally

the factorys warning light sender location.

2. Route the capillary tubing through the mount-

ing hole for the gauge and then through the

firewall, protecting the tubing from rough

edges. Form at least one 3" or larger loop of

tubing as it comes through the firewall and

route the remainder to the sender mounting

locations.

Temperature gauges measure the temperature

of any liquid their sender tip is submerged in. An

electrical temperature gauge is simpler and more

versatile for installation than a mechanical gauge

but is not quite as fast to respond to temperature

changes.

PRECAUTIONS

1. A temperature gauge requires that its sender

tip have a circulating flow around it to give an

accurate reading. For this reason, a T-fitting

cannot be used because it has no circulation

therefore the original warning light sender can-

not be operated off the same location. An ad-

ditional location may be available on the cyl-

inder head, intake manifold, or thermostat

housing but caution should be used in that

these locations may have different average

temperatures than the original warning light

sender location.

2. Do not over tighten the fittings or sender, par-

ticularly for mechanical gauges. The threads

are designed to strip before the engine com-

ponent can be damaged. The fittings use ta-

pered self-sealing threads and do not require

extreme force to seal properly.

3. Do not use sealing tapes or compounds on

electrical senders as this will disturb their

grounding connection to the engine resulting

in false low readings.

4. Take caution when uncoiling and routing the

mechanical gauges capillary tubing that you

do not bend it too sharply or flex it too often.

Any break in the inner tube will make the

gauge nonrepairable. A replacement service

is available only at the factory service center.

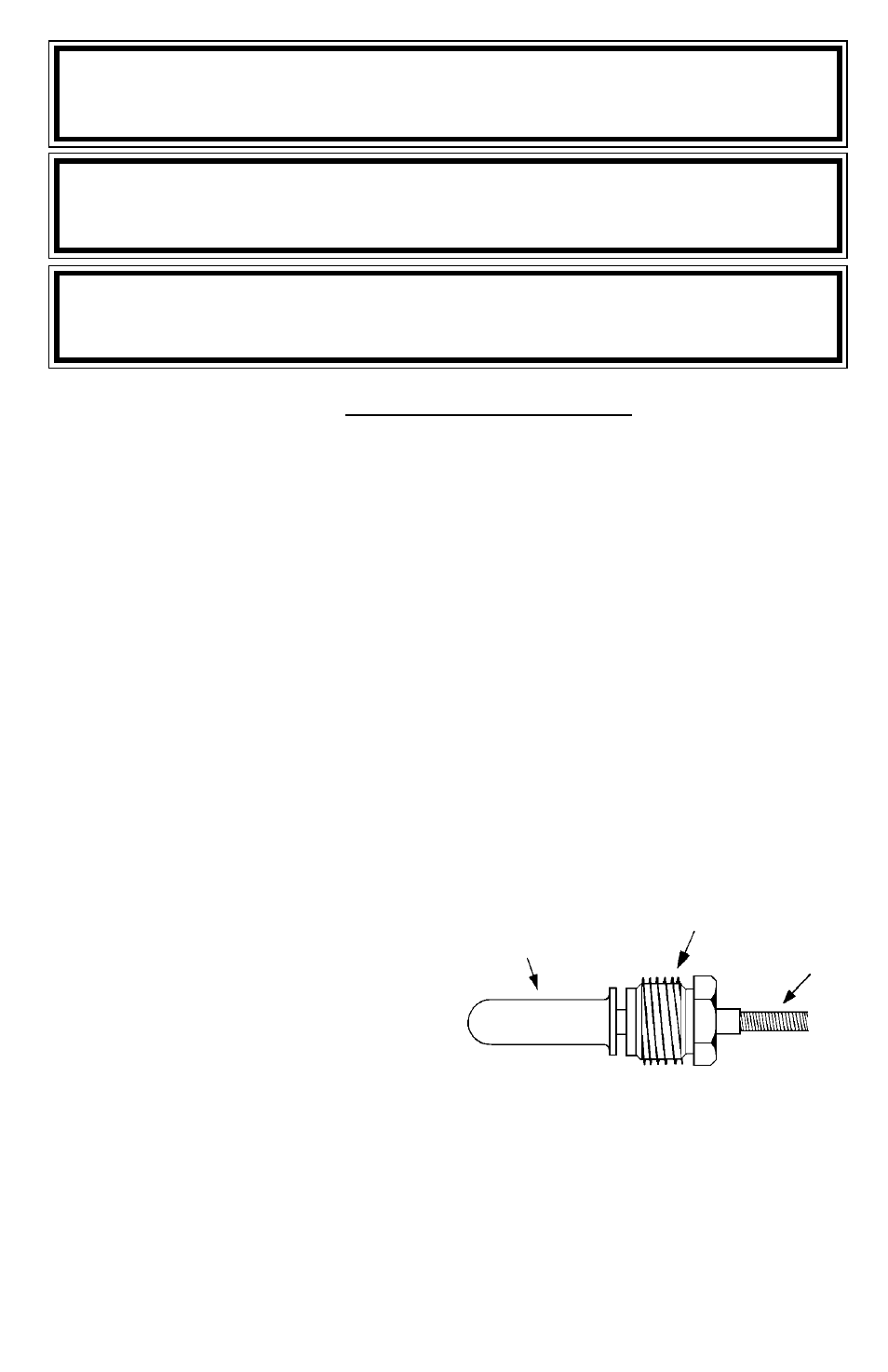

5. Always install the adapter fitting into the en-

gine first and then tighten the captive fitting

(Diagram 1) on the capillary tube to avoid

twisting the tubing.

CAPILLARY

TUBE

Diagram 1

CAPILLARY TUBE TIP

CAPTIVE FITTING

INDICADORES DE TEMPERATURA DE AGUA/

ACEITE INSTRUCCIONES - TENSIÓN 12 V

THERMOMÈTRE POUR EAU / HUILE -

INSTRUCTIONS

PARA NOMBRE, DOMICILIO Y TELEFONO DE IMPORTADOR: VER EMPAQUE.