Amerex 05618 User Manual

Page 7

6

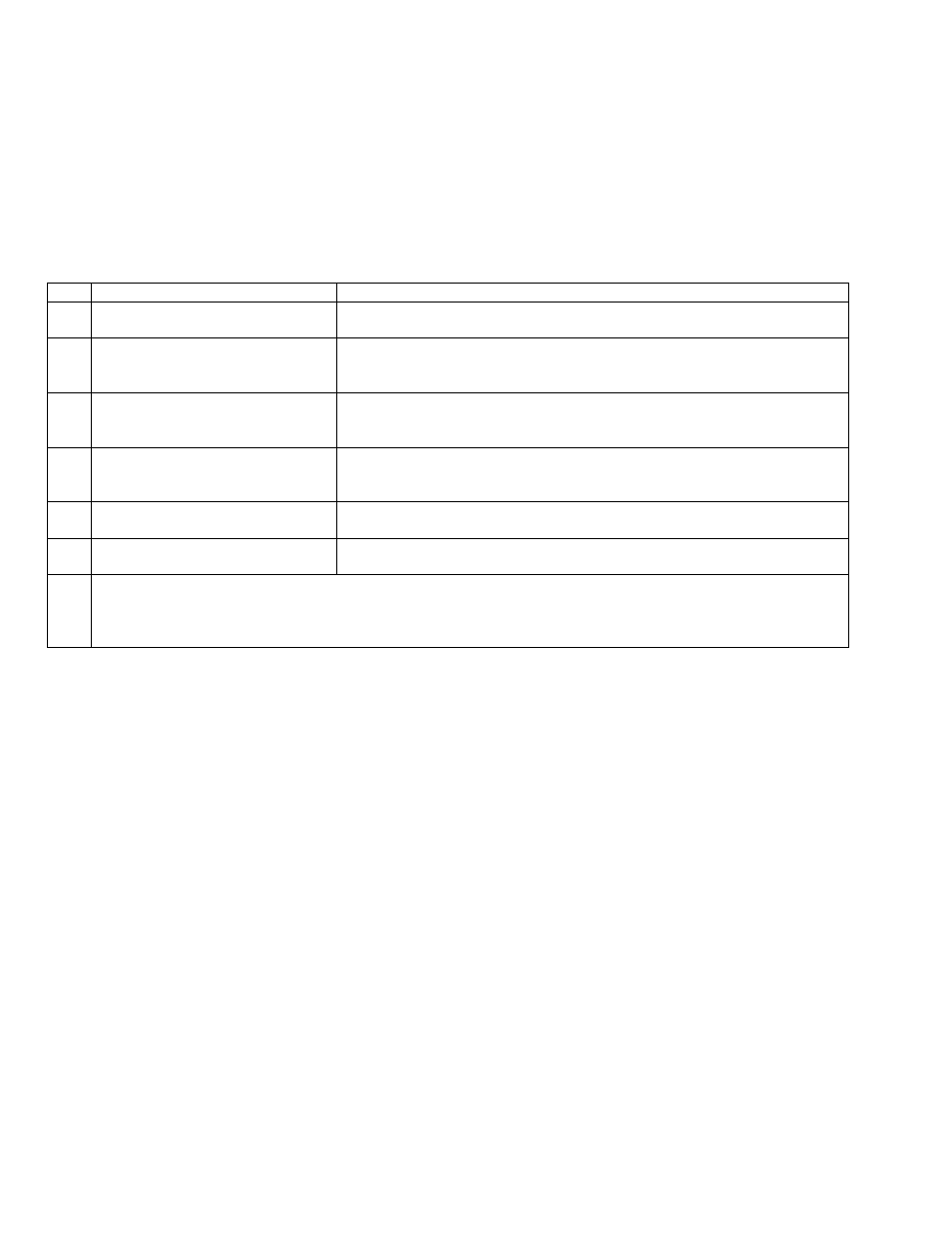

TROUBLE SHOOTING GUIDE

WARNING:

BEFORE ATTEMPTING TO CORRECT ANY LEAKAGE PROBLEM, BE SURE THAT THE

CYLINDER AND HOSE ARE COMPLETELY EMPTY AND DEPRESSURIZED.

NOTE: Check to determine the source of a leak before the extinguisher is emptied. Leakage repairs will

require that the Carbon Dioxide cylinder be completely empty and the valve assembly removed. When

reinstalling the cylinder valve assembly, the cylinder must be placed in a suitable securing vice and valve

installed to 150 ft. lbs. of torque.

PROBLEM

CORRECTIVE ACTION

1.

Leak at valve to cylinder

connection

Remove valve assembly, install new Teflon sealing tape, reinstall valve

to a maximum of 150 ft. lbs. torque.

2.

Leak through valve

Remove valve assembly, downtube, spring and valve stem assembly.

Install new valve stem assembly. Check valve seat for scratches or

foreign matter.

3.

Leak at safety relief nut

Remove safety nut, disc and gasket assembly. Replace with new

Amerex P/N 04000 safety nut, disc and gasket assembly. Tighten

assembly to 250 in. lbs. of torque.

4.

Leak

at base of “T” handle on

valve.

Remove valve assembly, downtube, spring and valve cylinder stem

assembly. Install new valve stem assembly. Check valve seat for

scratches or foreign matter.

5.

Leak at any hose connections

Tighten hose connections and check for hose coupling damage.

Replace hose assembly as necessary.

6.

Leak in the cylinder

Contact Amerex if under warranty, otherwise mark “REJECTED” and

return to owner.

NOTE: When valve removal is performed at hydrotest, the cylinder neck threads must be examined per

CGA C-

6. “Cylinders shall be rejected if the required number of effective threads is materially reduced so

that a gas tight seal cannot be obtained by reasonable valving methods. Common defects are worn or

corroded crests and broken or nicked threads.”