System Sensor B401BH User Manual

System Sensor Equipment

D400-50-00

1

I56-0612-006R

B401BH and B401BHA

Sounder Bases

INSTALLATION AND MAINTENANCE INSTRUCTIONS

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

BEfORE INSTALLINg

Please read the System Smoke Detector Application Guide, which provides

detailed information on detector spacing, placement, zoning, wiring, and

special applications. Copies of this manual are available from System Sen-

sor. NFPA 72 and NEMA guidelines should be observed. (For installation

in Canada, refer to CAN/ULC-S524, Standard for the Installation of Fire

Alarm Systems and CEC Part 1, Sec. 32.)

NOTICE: This manual should be left with the owner/user of this equipment.

IMPORTANT: The detector used with these bases must be tested and main-

tained regularly following NFPA 72 requirements. The detector should be

cleaned at least once a year.

gENERAL DESCRIpTION

Models B401BH and B401BHA sounder bases are intended for use with Sys-

tem Sensor 400 Series plug-in sensor heads in conventional 2-wire plug-in

systems. Refer to systems manuals for the maximum allowable number of

units per loop. The B401BH requires an external 24VDC (nominal) supply

with reverse polarity capability. The connections of the external supply (termi-

nals 1 and 2) and the initiating loop (terminals 3, 4, and 5) are isolated in the

B401BH to prevent electrical interaction between them.

When the detector head’s visible LEDs are latched on for approximately 10

seconds, the associated horn sounds. A loop of horns can be made to sound

by reversing the polarity of the external supply.

NOTE: When the associated system is NOT used as a supplementary evacua-

tion system, the external 24VDC supply must be treated as a component of the

main power supply system with the result that it falls under the requirements

of NFPA 72.

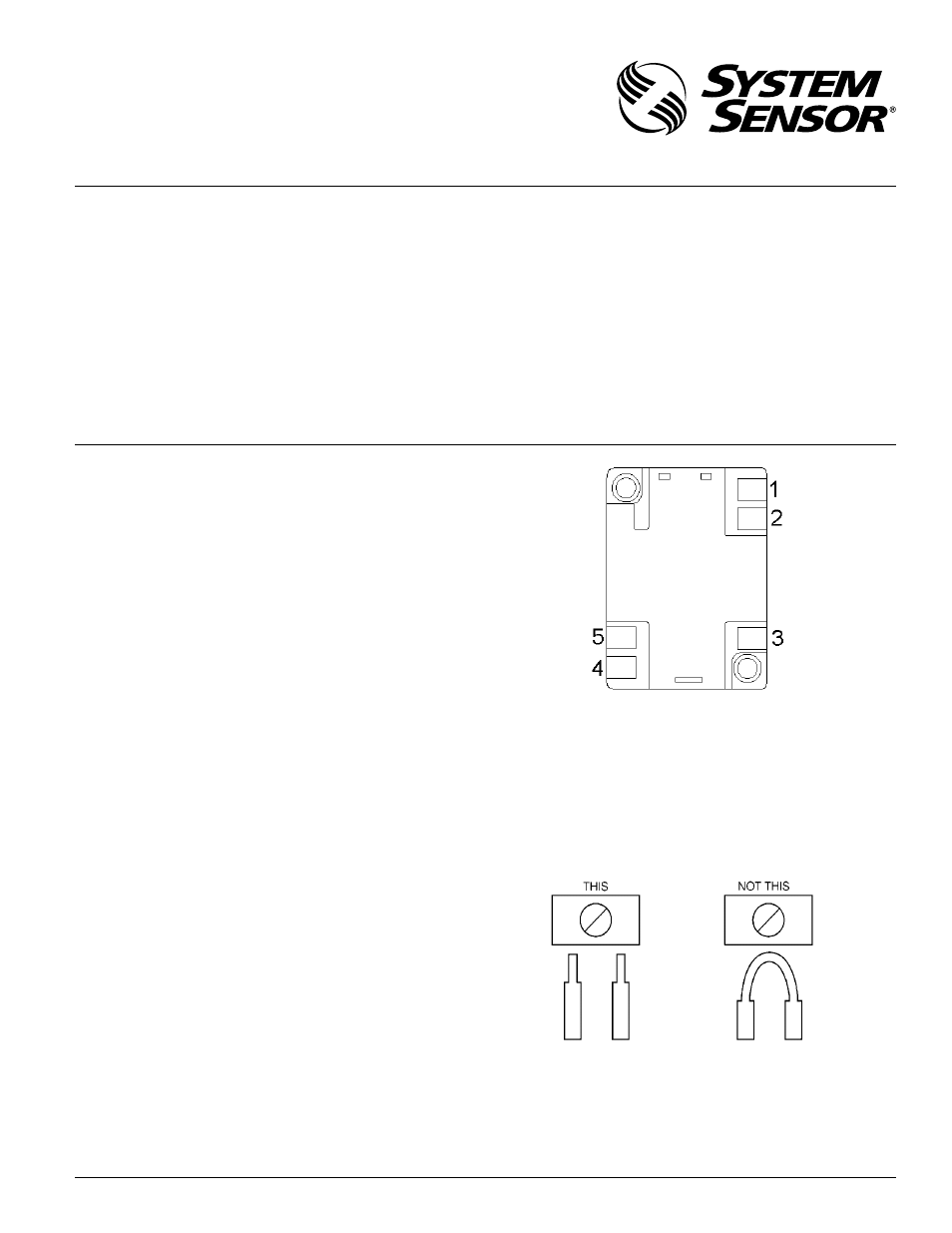

B401BH AND B401BHA TERMINALS

No. Function

1

External Supply Positive (+)

2

External Supply Negative (–)

3

Negative (–) V

4

Positive (+) V In

5

Positive (+) V Out

Terminals 3, 4, and 5 are used for the communication/initiating circuit.

INSTALLATION WIRINg gUIDELINES

All wiring must be installed in compliance with the National Electrical Code

and all applicable local codes and any special requirements of the authority

having jurisdiction, using the proper wire size. The conductors used to con-

nect smoke detectors to control panels and accessory devices should be color-

coded to reduce the likelihood of wiring errors. Improper connections can

prevent a system from responding properly in the event of a fire.

SpECIfICATIONS

Base Diameter:

6 inches (152 mm)

Base Height (less base and sensor):

0.75 inches (19mm)

Weight:

0.3 lb. (140 g)

Operating Temperature Range:

14° to 140°F (–10° to +60°C)

Operating Humidity Range:

10% to 95%, noncondensing

Electrical Ratings

Voltage:

17 to 32 VDC

Standby Current:

1.0 mA maximum

Alarm Current:

15 mA maximum

Maximum Ripple Voltage:

10% of supply voltage

Start-up Capacitance:

200 µF

Horn Input Current Requirement:

600 µA maximum

Sound Output:

Greater than 90 dBa measured in anechoic room at 10 feet (3 meters),

24 volts. 85 dBa minimum measured in UL reverberant room.

For signal wiring (the wiring between interconnected detectors), it is recom-

mended that the wire be no smaller than AWG 18. However, the screws and

clamping plate in the base can accommodate wire sizes up to AWG 12. The

use of twisted pair wiring or shielded cable for the power (+ and –) loop is

recommended to minimize the effects of electrical interference on the initiat-

ing loop.

Begin electrical connections by stripping about 3/8” insulation from the end

of the wire. Then, slide the bare end of the wire under the clamping plate and

tighten the clamping plate screw. Break the wire at each terminal to ensure

that the connections are supervised, as shown in Figure 2.

I56-06

12-006R

fIgURE 1. TERMINAL LAyOUT:

C0471-00

fIgURE 2.

C0473-00

DO NOT loop the wire under the clamping plate.

Check the zone wiring of the detector base before the detector heads are in-

stalled. Perform continuity, base polarity, and dielectric tests on the wiring.

Smoke detectors and alarm system control panels have specifications for al-

lowable supervision current. Consult the control panel manufacturer’s speci-

fications for the total loop current supervision allowed for the control panel

being used before wiring the detector loops.