Kfm series, General pump – General Pump KFM Repair Manual User Manual

Page 12

GENERAL PUMP

A member of the Interpump Group

KFM SERIES

Page 12

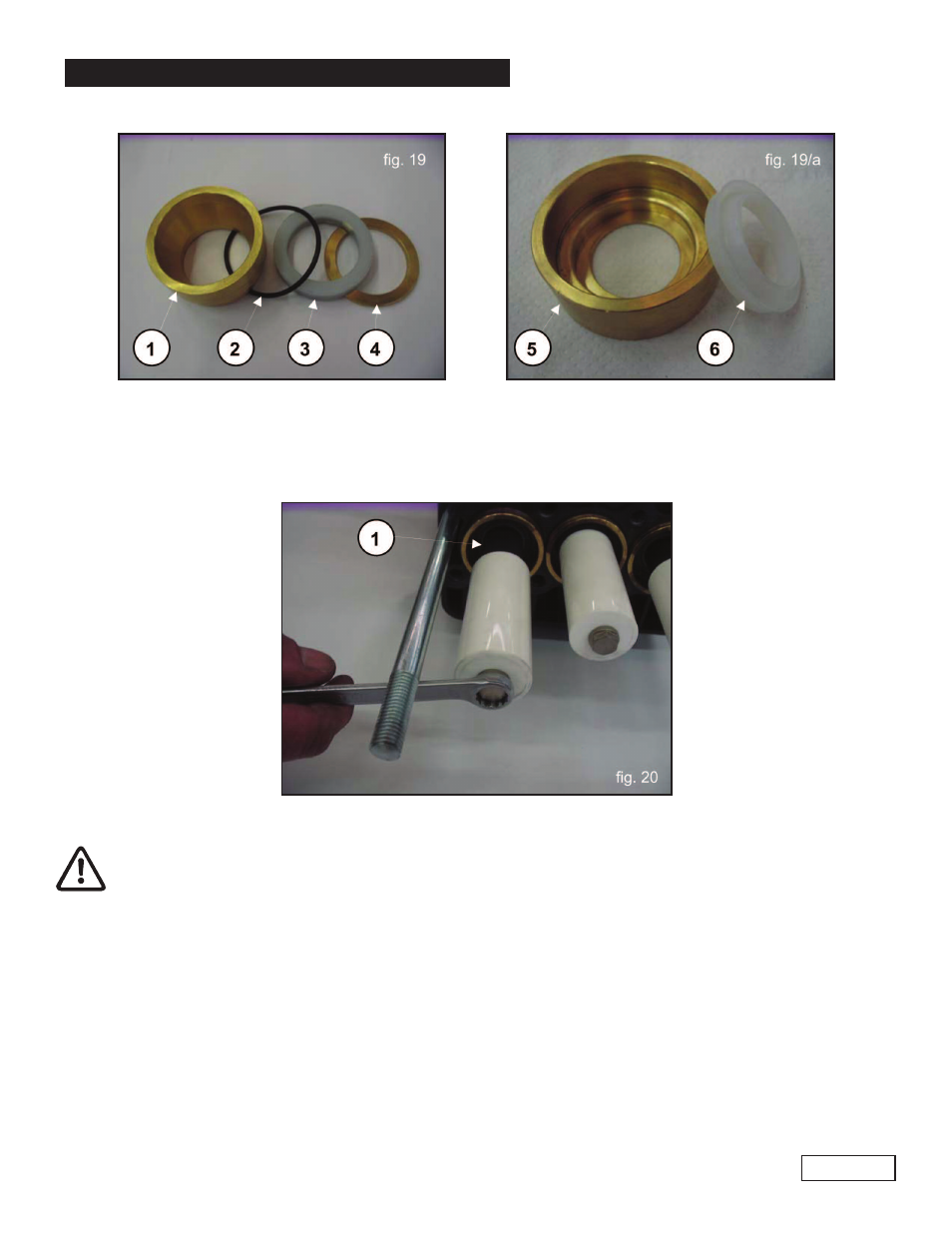

2.2.4 Plunger Unit Disassembly

The plunger unit does not require periodical maintenance. Service interventions are limited to visual

inspections only. For plunger unit extraction, operate as follows:

A) Pull out the spacer and loosen the M7 x 1 plunger fastening screws as shown in fig. 20.

B) Check and verify their state of wear, and replace them if necessary. Check and verify the state of wear of the

spacers located behind the plunger (fig. 20, pos. 1), and replace them if necessary.

At each disassembly, all plunger unit O-rings MUST be replaced.

2.2.5 Head assembly - seals - plunger unit

Reassemble the various components by inverting the operations previously listed in paragraph 2.2.3, paying careful

attention to the following:

A) Seal packing: respect the same order followed during disassembly.

B) Lubricate components 2, 3 and 6 with silicone grease type (#F12001600); this operation is also considered

necessary in order to facilitate the setting of the seal lip pn the plunger.

C) For correctly assembling the HP seals in their related seats on the head without damaging the lips, use the

correct tools depending on the plumbing assembly diameters as indicated in Chapter 4.

D) Reassemble the plungers by fastening the screws with a torque wrench, respecting the fastening torque

value inicated in Chapter 3.

E) Assemble the head: for fastening torque values and fastening sequences, follow the instructions in Chapter 3.